Subscribe to our newsletter and always be the first to hear about what is happening.

A Detailed Introduction to Talc

Jun 22, 2024

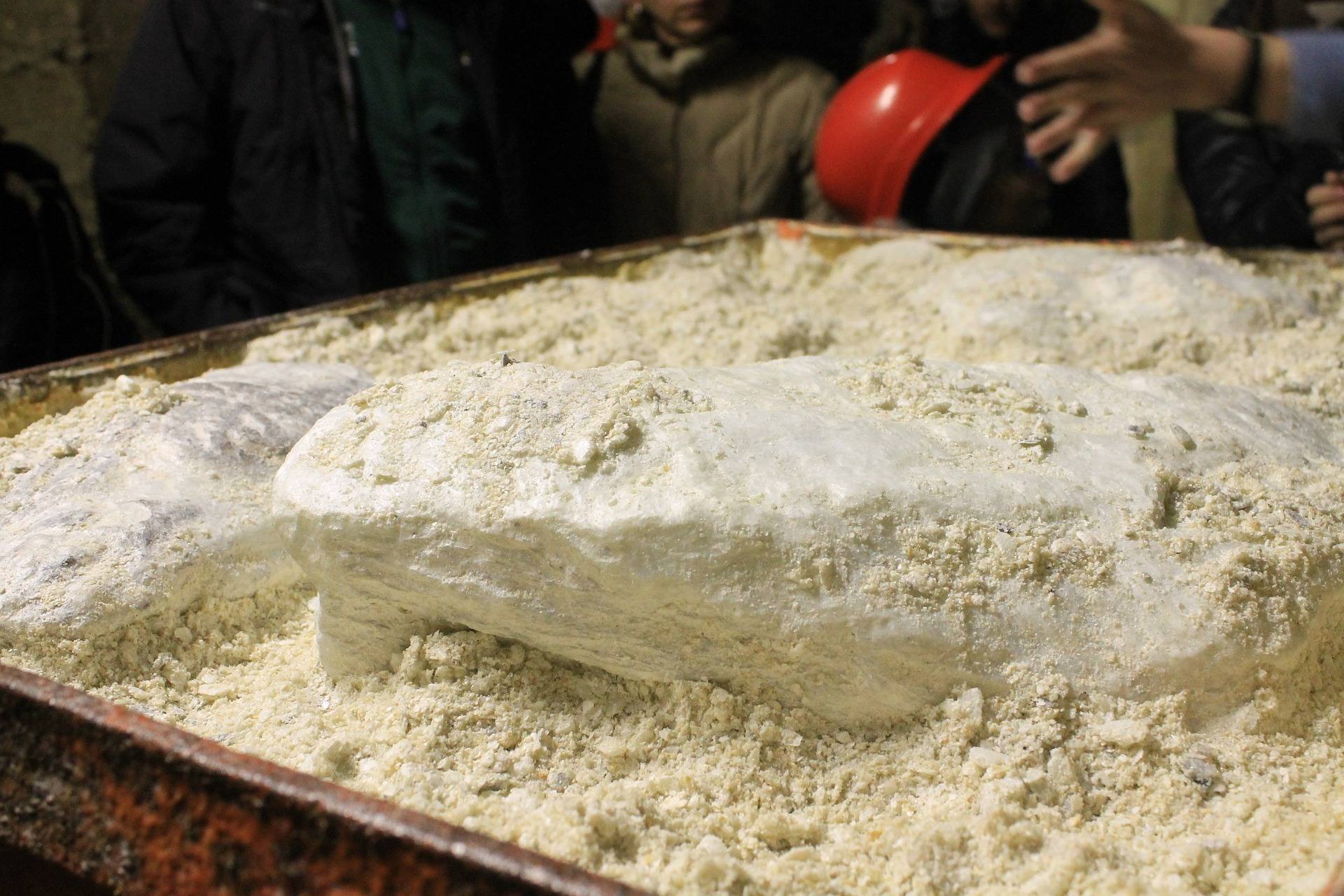

Talc is a silicate mineral with a chemical composition of Mg3Si4O102. It is a trioctahedral mineral with a soft, smooth feel and a low Mohs hardness (1). It is often in the form of blocks, blades, fibers or radial aggregates. The color of talc is mostly white or off-white, but it can also have various colors due to other impurities. Due to its unique layered structure and lubricity, talc is widely used in industry, such as as a filler, reinforcing agent and insulating material.

There are two main ways to mine talc: open-pit mining and underground mining. Open-pit mining is suitable for talc mines above the surface, while underground mining is used for ore bodies below the surface. During the mining of talc, attention should be paid to the crushing of the ore because it is relatively fragile. After a series of processes such as crushing and grinding, talc ore can be made into talc powder of different specifications for use in various industrial fields.

Talc is widely used in many industries due to its unique physical and chemical properties. In the cosmetics industry, talc is used as a filler for moisturizing powder, beauty powder, etc. In the coatings industry, talc is used as a white body pigment for various industrial coatings. In the papermaking industry, talc is used as a filler for paper and paperboard. In addition, talc is also used as a filler and reinforcing agent in industries such as plastics, rubber, cables, and ceramics.

In the industrial industry, talcum powder is mainly used to improve the mechanical properties of products, such as improving the rigidity, heat resistance, creep resistance, etc. of plastic products. The addition of talcum powder can significantly improve the rigidity and heat resistance of plastic products, while also reducing production costs and improving the market competitiveness of products.

In the construction industry, talcum powder can be used to improve the performance of building materials, such as increasing the strength and durability of concrete. Talc is also widely used in architectural coatings, which can improve the hiding power and stability of coatings, while also providing certain thermal insulation and aging resistance effects.

In the automotive industry, talcum powder is mainly used in the production of automotive interior and exterior parts, such as dashboards, door panels, pillars, etc. The addition of talcum powder can improve the mechanical strength and rigidity of these parts, while also reducing the overall weight of the car, contributing to the lightweight design of the car.

In the aerospace industry, talc is widely used in the manufacture of high-temperature structural parts due to its excellent high-temperature resistance.The high-temperature stability of talc makes it an indispensable material in this industry.

In the pharmaceutical and cosmetic industries, talc is used as a filler and coating agent to improve the quality and safety of products. The whiteness and chemical stability of talc make it widely used in these industries.

High-quality talcum powder is usually white or light gray, with a fine and smooth texture and no visible impurities. Low-quality talcum powder may be darker in color, rough in texture, and may contain other impurities.

The water content of talcum powder will affect its performance and application effect. Generally speaking, high-quality talcum powder has a lower water content and is not easy to absorb moisture and become soft. The water content can be determined through simple experiments, such as placing the powder in a dry environment and observing its moisture absorption.

The particle size of talcum powder directly affects its application performance. High-quality talcum powder has uniform particle size and fine particle size, which helps to improve the gloss and smoothness of the product. The particle size distribution can be tested using equipment such as laser particle size analyzer.

The main component of talc is magnesium silicate, but it may contain a certain amount of impurities, such as aluminum silicate and iron. Chemical analysis methods can be used to determine the chemical composition of talc to ensure that it meets the requirements of specific industries.

As an industrial raw material widely used in many industries, talc purification technology is directly related to product quality and effective utilization of resources. In the purification process, how to balance product quality and resource waste is particularly important..

Flotation method uses the difference in physical and chemical properties between talc and other mineral surfaces, and adds collectors and foaming agents to combine talc particles with water to form foam, thereby achieving purification. This method is simple to operate, but it is highly dependent on chemicals and has a certain impact on the environment.

The hand selection method is to purify talc powder and gangue minerals by manual selection according to their different slipperiness. Although this method has high purity, it is labor-intensive and has low production efficiency, making it unsuitable for large-scale production.

Magnetic separation is a method of separating minerals by using a magnetic field, using the magnetic difference between talc and associated minerals. This method is suitable for processing ores with high iron content, but the equipment investment is relatively large.

https://www.mdoresorting.com/mingde-ai-sorting-machine-separate-phosphorite-ore

Photoelectric beneficiation is a method that uses the difference in reflection characteristics of talc and impurity minerals under different light to identify and separate them through photoelectric sensors. This method has high accuracy, but the equipment is complex and the maintenance cost is high.

Chemical treatment is to remove impurities from talc through chemical reactions such as acid washing and alkali washing. This method can effectively remove specific types of impurities, but it may cause pollution to the environment.

The heat treatment method is to heat the talc to a high temperature and remove impurities by high-temperature calcination. This method can significantly improve the whiteness and physical and chemical properties of talc, but it consumes a lot of energy.

The waste of resources in the process of talcum powder purification is mainly manifested in the following aspects:

1. Energy consumption: In the purification process, especially heat treatment and chemical treatment, the energy consumption is huge, which is not conducive to sustainable development.

2. Reagent use: Processes such as flotation require a large amount of chemical reagents, which may be harmful to the environment and have high costs.

3. Tailings accumulation: The tailings generated during the beneficiation process have not been effectively utilized, resulting in a large amount of resource discard.