Subscribe to our newsletter and always be the first to hear about what is happening.

AI intelligent Sorting Machine: A New Choice for Ore Sorting

Jul 20, 2024As the number of ore resources with low mining difficulty and good quality is decreasing, mining companies are gradually falling into trouble, especially low-grade mining companies. How to improve the economic value of mines? Reduce the overall mining and selection costs? It is an important problem facing its development, especially at the current stage, the mining and selection technology and production process improvements of industrial and mining enterprises are in a stagnant stage. The only best choice is to break the existing thinking mode.

In view of the current situation of industrial and mining enterprises, there will be no major breakthroughs in mining and selection technology for the time being. Only by looking for external breakthroughs in the production process can new innovations be achieved. It is obvious that the best solution is to start with the sorting after the crushing and dissociation of the original ore.

Some people will definitely ask why? In fact, it is very simple. We need to understand what ore sorting is and what is the difference between the sorting mentioned and the sorting at the current stage. The ore sorting mentioned here is to enrich the grade of the ore in advance before grinding and crushing, and to raise the pre-throwing waste tailings to reduce the amount of ore entering the subsequent process, saving a lot of costs for the subsequent process. At the same time, the pre-throwing waste tailings have not been ground and have certain economic value.

Take an example of economic benefits. Let's do some economic calculations. Assuming that an industrial and mining enterprise mines 1 million tons per year, before using an ore sorter, the original production process is mining-crushing-grinding-flotation. According to the calculation of $6.3 per ton for grinding and flotation, the annual cost before using an ore sorter is about 6.3 million dollar. After using an ore sorter, each ore sorter sorts about 25 tons per hour (the smaller the particle size, the lower the hourly sorting output. In this example, the particle size of the ore particles is in the range of 1cm-4cm). The sorting cost is mainly electricity. The electricity cost per machine is $1.37 per hour, and the sorting cost per ton is about $0.137. According to 20% of the discarded tailings, there is no need for subsequent grinding and flotation, and the annual savings can reach about 1.1 million dollar. In addition, the discarded tailings can still be backfilled in the mine, or sold as other construction, road construction and other materials. The overall estimated annual output value is at least more than 1.37 million dollar. Among them, Mingde Optoelectronics' artificial intelligence ore sorter was born. Committed to the introduction, research and development, promotion and application of artificial intelligence ore sorting technology.

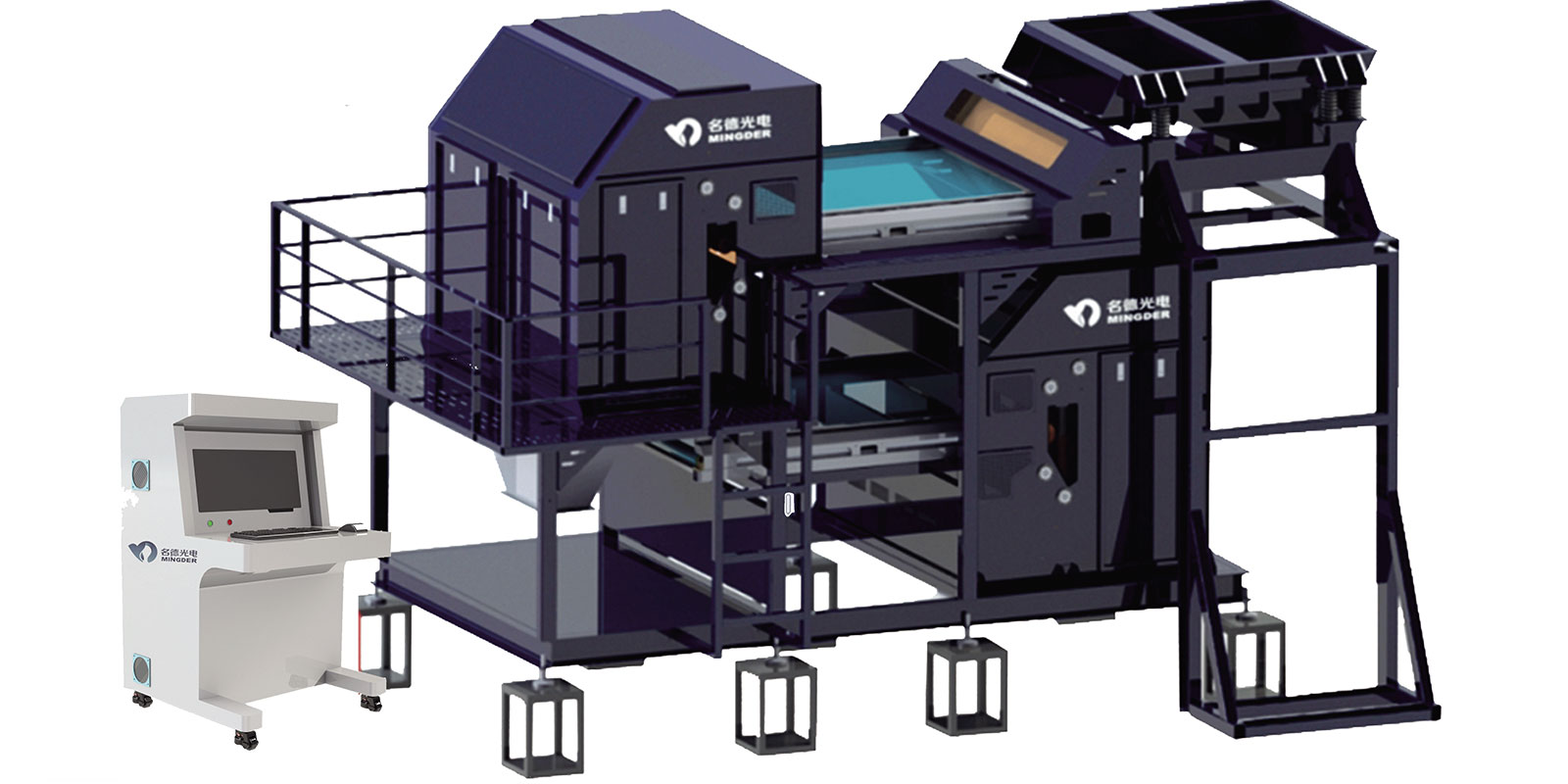

AI Ore Sorting Machine

AI Ore Sorting Machine is a device that uses the principle of photoelectric sorting, artificial intelligence means, and AI photoelectric sorting technology. After the original ore is crushed and before flotation, it can be sorted in a composite manner according to the different surface characteristics of the original ore, such as texture, color, texture, shape and other multi-dimensional characteristics, to achieve ore grade enrichment and pre-disposal of tailings. Intelligent sorting equipment. It also has the following advantages

https://www.mdoresorting.com/mingde-ai-sorting-machine-separate-quartzmicafeldspar-from-pegmatite

Adjustable parameters: Sorting models can be established according to different sorting requirements to meet personalized sorting requirements;

Automatic sorting: No manual work is required to achieve intelligent ore sorting with high sorting efficiency;

Intelligent: It can continuously learn through the learning mode to further improve the overall sorting effect;

Application range: Mainly in the sorting of talc, wollastonite, potassium feldspar, fluorite, quartz, calcite, lithium ore, gold ore, iron ore, lead-zinc ore, high-crystalline silicon and other ores with visible differences;

Applicable fields: new and old mines, historically abandoned low-grade ores and other industrial and mining enterprises.