Subscribe to our newsletter and always be the first to hear about what is happening.

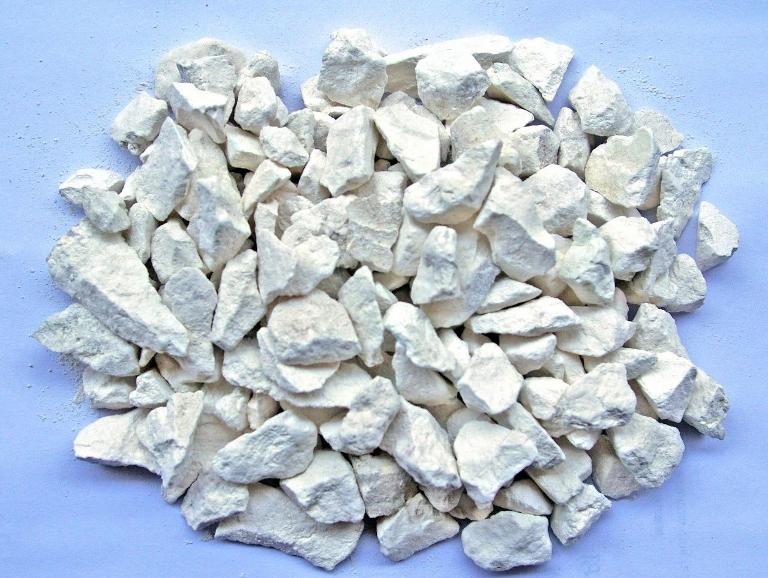

An Article on Limestone

Jun 14, 2024Limestone is a common sedimentary rock, the main component of which is calcium carbonate (chemical formula: CaCO₃). Limestone can be directly processed into stone and burned into quicklime. Quicklime becomes slaked lime after adding water. The main component is calcium hydroxide (Ca(OH)₂), which is often used in building materials and industrial raw materials.

The physical properties of limestone include density, porosity, hardness, strength, decomposition temperature, thermal expansion coefficient, specific heat capacity, thermal conductivity, color, etc. For example, the density of limestone is approximately between 2.65 and 2.80 g/cm³, the hardness is between 2 and 4 on the Mohsscale, and the reference value of compressive strength is approximately 7.85 to 196.14 Mpa.

The chemical properties of limestone mainly depend on the chemical properties of its main component, calcium carbonate. When heated to 898~910℃ under normal pressure, limestone will decompose into lime and carbon dioxide. The calcium carbonate in limestone reacts with almost all strong acids to form corresponding calcium salts and release carbon dioxide at the same time. In addition, the solubility of calcium carbonate in limestone in water containing carbon dioxide is much higher than that in water without carbon dioxide, because calcium carbonate generates more soluble calcium bicarbonate at this time.

Limestone is widely used in building materials, roads, metallurgy, chemical industry and other industries.

Limestone can be used to produce lime and slaked lime.Quicklime can be used to produce building materials such as gypsum products, putty, and paint.At the same time, limestone can also be directly used to produce concrete, mortar and other building materials.

Limestone can be used as a chemical raw material to produce a variety of chemical products, such as calcium chloride, calcium nitrate, calcium hydroxide, etc. These chemical products are widely used in food, medicine, pesticides and other fields.

In the metallurgical industry, limestone can be used as an auxiliary material for desulfurization and dephosphorization of molten metals. The calcium sulfate and calcium phosphate produced can be recycled as by-products. At the same time, limestone can also be used to produce metal elements such as calcium and magnesium.

Since limestone can react with acidic substances to form precipitates, it can be used in environmental protection fields such as wastewater treatment and flue gas desulfurization. For example, limestone can react with acidic wastewater to form precipitates, so that harmful substances in the wastewater can be removed; in flue gas desulfurization, limestone can react with sulfur dioxide to form calcium sulfate, thereby achieving the purpose of desulfurization.

Limestone can also be used to produce glass, ceramics, coatings and other products; in agriculture, limestone can be used as fertilizer to increase the pH value of the soil; in medicine, limestone can be used to produce some drugs and reagents.With the continuous development of science and technology, the application prospects of limestone will be broader.

Limestone mining generally follows these basic steps:

1) Exploration and evaluation: First, geological exploration is carried out on potential limestone mining areas to evaluate the reserves, quality and economic feasibility of limestone mining.

2) Mining Permits: Obtain necessary mining licenses and environmental impact assessment approvals to ensure mining activities are carried out legally and in compliance with regulations.

3) Selection of mining method: According to the characteristics and geographical location of the limestone deposit, the appropriate mining method is selected. Common methods include open pit mining and underground mining.

4) Mining operations: In open-pit mining, step-by-step or slope mining methods are usually used to dig downwards. Underground mining may use chamber-pillar method, staged caving method, etc.

5) Stone processing: The mined limestone needs to go through crushing, screening and other processing processes to meet different application requirements.

6) Transportation and Storage: The processed limestone is transported to the processing plant or storage site by truck, rail or belt conveyor.

7) Environmental protection and reclamation: Measures should be taken to prevent environmental pollution during the mining process, and land should be reclaimed after mining to restore the ecological environment.

Limestone mining technology and equipment include:

1) Drilling equipment: used to drill holes in limestone for blasting operations.

2) Blasting equipment: used to separate limestone from rock.

3) Loading machinery: such as excavators, loaders, etc., used to load the limestone after blasting.

4) Transportation equipment: such as trucks, rail cars, conveyor belts, etc., used to transport limestone from the mining site to its destination.

5) Crushing and screening equipment: including jaw crusher, cone crusher, hammer crusher, vibrating screen, etc., used to crush limestone into products of different specifications.

6) Sorting equipment: including gravity sorting equipment, magnetic separation equipment, photoelectric sorting equipment, etc., used to separate crushed limestone and impurities

During limestone mining, the following safety and environmental protection measures must be taken:

1) Safety procedures: Ensure that all staff follow safe operating procedures to avoid accidents.

2) Dust prevention measures: Take measures such as spray dust reduction and closed transportation to reduce the harm of dust to the environment and human health.

3) Noise control: Take sound insulation measures to reduce noise pollution generated by mining activities.

4) Water resource protection: Rationally utilize water resources and prevent water pollution.

5) Waste disposal: Properly dispose of waste generated during the mining process to reduce the impact on the environment.

Recent trends in limestone mining include:

1) Intelligent mining: Use advanced automation and information technology to improve mining efficiency and safety.

2) Green mining: focus on environmental protection and adopt more environmentally friendly mining technologies and management methods.

3) Energy conservation and emission reduction: Reduce energy consumption and emissions by improving processes and equipment.