Subscribe to our newsletter and always be the first to hear about what is happening.

Application Scope, Advantages and Disadvantages of Different Mineral Processing Methods Part 1

Aug 02, 2024Ore sorting is a very critical step in mining production, which directly affects the recovery rate of ore, resource utilization rate and the quality of the final product. Through effective sorting, useful minerals can be separated from waste rocks or low-grade minerals, thereby increasing the overall value of the ore. In addition, ore sorting also helps to reduce energy and material consumption in subsequent processing, reduce production costs, and reduce environmental impact. Different ores use different sorting methods according to their physical and chemical properties.

Different ore beneficiation methods have their own applicable ores and advantages and disadvantages. Below we will introduce the eight main sorting methods on the market in detail through two articles:

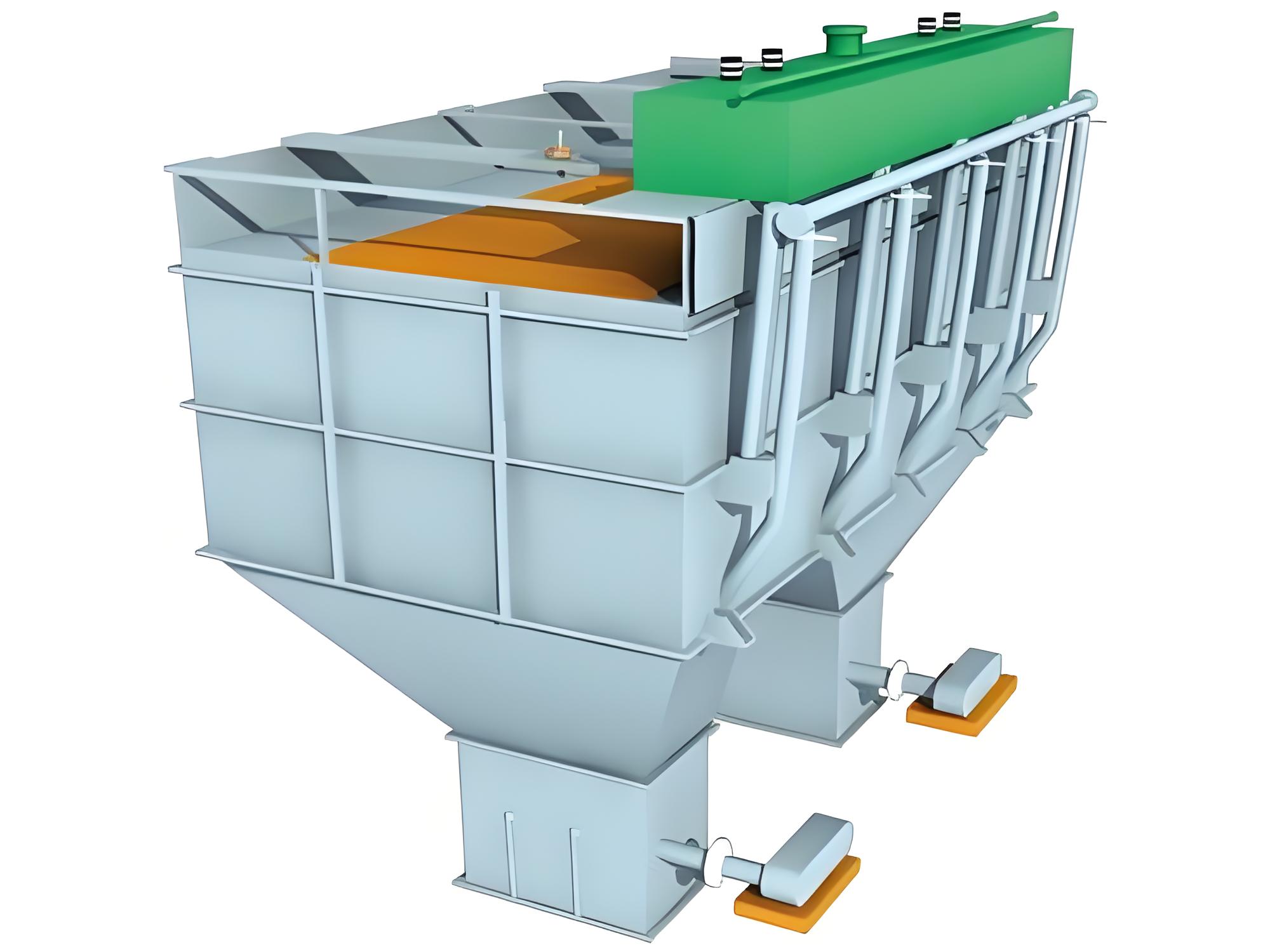

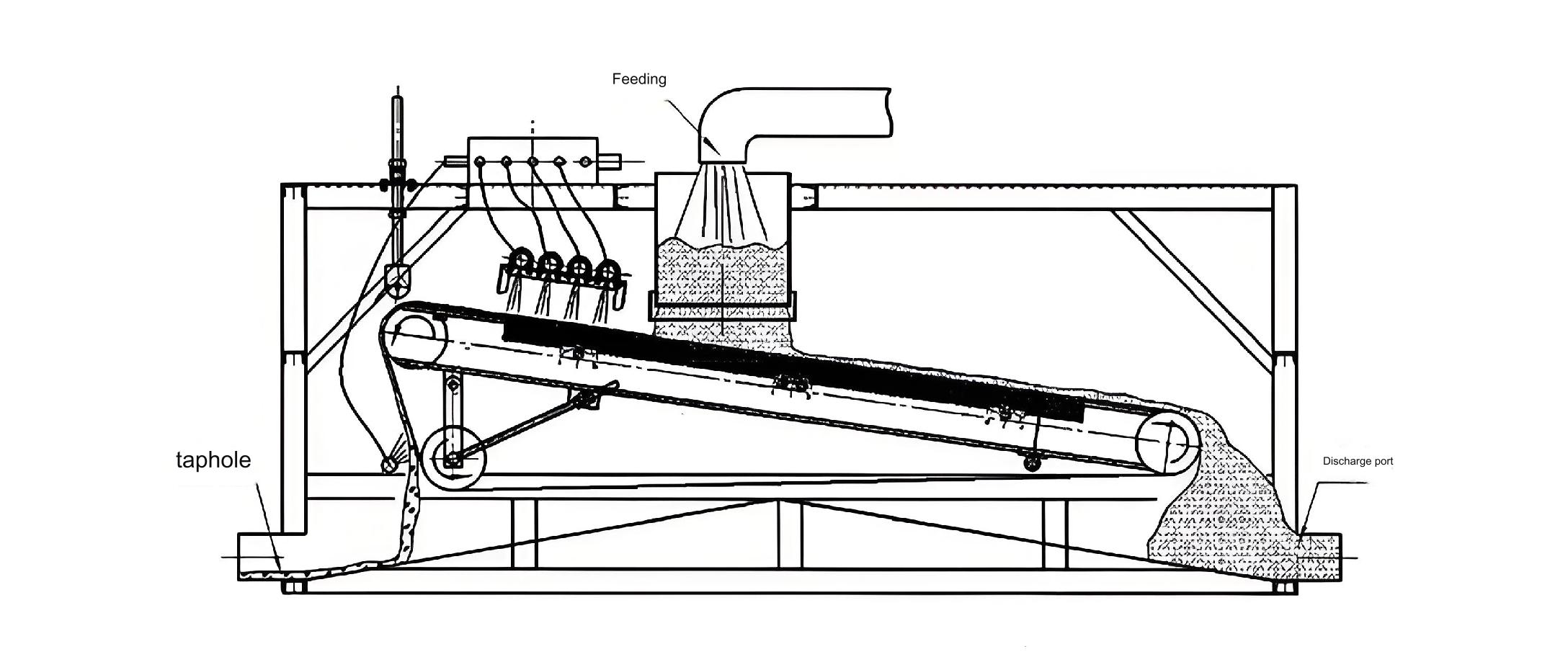

1. Gravity Separation Method

Gravity separation method is a method of sorting based on the difference in the settling velocity of different mineral particles under the action of gravity. This method is suitable for processing ores with a large density difference between useful minerals and gangue. Gravity separation equipment usually operates in water or other fluid media, using gravity or mechanical force to separate mineral particles. The types of ores that can be separated are mainly the following:

(1) Tungsten, tin, and gold ores: Gravity separation is a traditional method for processing these metal ores, especially for the beneficiation of placer gold and placer tin ores.

(2) Rare metal ores: Placer ores containing rare metals such as niobium, tantalum, titanium, and zirconium are also often processed by gravity separation.

(3) Weakly magnetic iron ore: Gravity separation can be used to separate weakly magnetic iron ore, manganese ore, chromium ore, etc.

(4) Non-metallic ores: In the non-metallic mineral processing industry, gravity separation is also widely used to process ores such as asbestos, diamonds, kaolin, apatite, and pyrite.

Advantages of gravity separation

(1) Low cost: The production cost of gravity separation is relatively low because it does not require complex chemical reagents and high-energy consumption equipment.

(2) Environmental friendliness: Since no chemical reagents are used or only a small amount is used, the gravity separation method has less pollution to the environment.

(3) Wide applicability: The gravity separation method is suitable for processing ores with a large density difference between useful minerals and gangue, especially showing good results when processing coarse-grained minerals.

(4) Simple equipment: Gravity separation equipment usually has a simple structure and low maintenance cost.

Disadvantages of gravity separation method

(1) Low efficiency in processing fine-grained ores: Gravity separation is not efficient when processing ores less than 0.1 mm, and the separation effect on fine-grained ores is limited.

(2) Limited equipment processing capacity: For some materials, the processing capacity of gravity separation equipment may not be sufficient to meet the needs of large-scale production.

(3) Technical challenges: The optimization and control of the gravity separation process is relatively complex and requires professional knowledge and skills.

The advantages of gravity separation are mainly reflected in its economy and environmental friendliness, while the disadvantages are concentrated in the processing of fine-grained ores and improving equipment processing capacity.

When processing fine-grained ores, the main problems encountered by the gravity separation method include poor dispersion of fine-grained materials in the gravity field, easy agglomeration, and reduced specific gravity difference with the gangue, all of which will lead to reduced gravity separation effect. In addition, the surface energy of fine-grained minerals increases, making them easy to adsorb on other particles, increasing the difficulty of separation. Therefore, in practical applications, whether to use the gravity separation method should be selected according to the specific characteristics of the ore and production requirements.

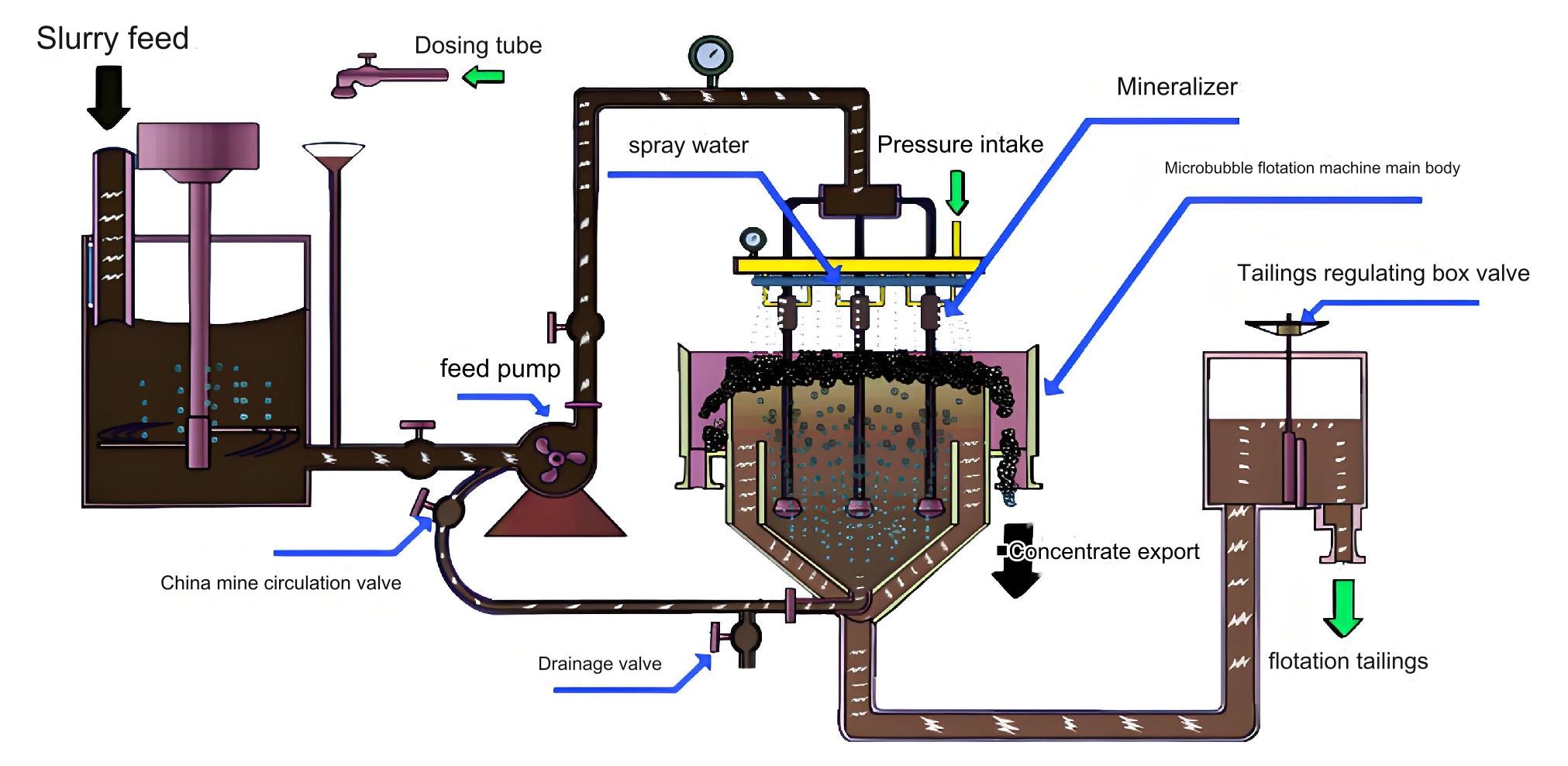

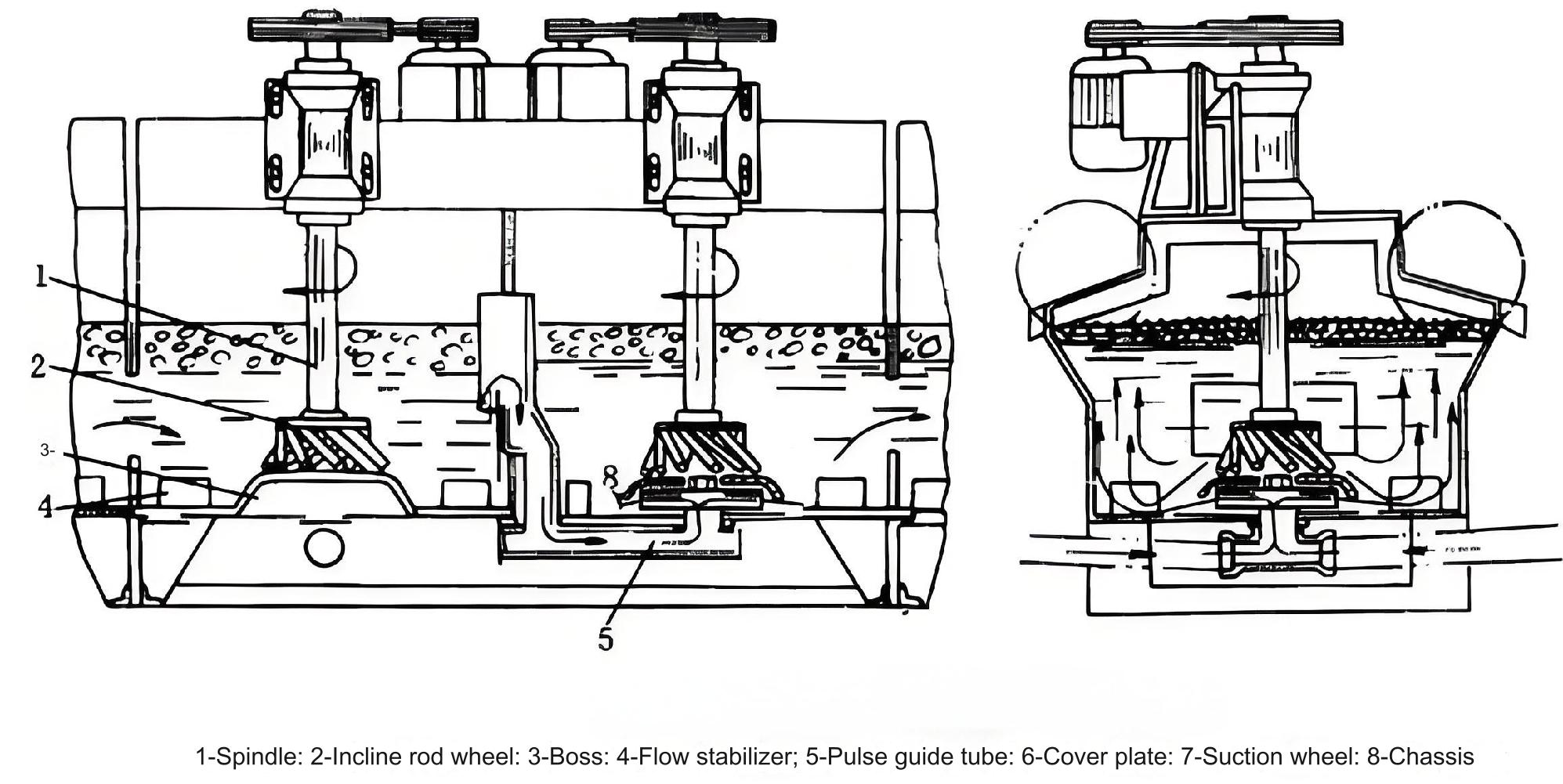

2. Flotation Method

Flotation is a physical and chemical separation method widely used in mineral processing. It uses the difference in affinity between minerals and bubbles to achieve mineral separation.

Flotation has important applications in many industries. In the field of ore sorting, it is applicable to a variety of non-ferrous metals, rare metals and non-metallic mines, including copper, lead, zinc, gold, silver, nickel, cobalt, tungsten, molybdenum, tin, antimony, bismuth, titanium, zirconium, vanadium, chromium, lithium, beryllium, strontium, barium, calcium, magnesium, boron, silicon, phosphorus, sulfur, graphite, talc, gypsum, bentonite, diatomaceous earth, etc. In addition, flotation is also used for coal washing and processing of other non-metallic ores.

Flotation is a widely used beneficiation method for mineral processing, especially for sulfide minerals and certain non-sulfide minerals. The following are several types of ores for which flotation usually achieves the best results:

(1) Copper sulfide ore: Flotation is the preferred method for processing copper sulfide ore because copper sulfide minerals have good floatability and can be effectively separated from the ore by using specific collectors and regulators.

(2) Polymetallic sulfide ore: For ores containing polymetallic sulfide minerals such as lead, zinc, and gold, flotation can effectively separate and recover these metals.

(3) Certain non-metallic minerals: Flotation is also suitable for the extraction of non-metallic minerals, such as phosphate, limestone, fluorite, etc. These minerals can be separated from other minerals through flotation processes to improve the purity of the product.

(4) Refractory gold ore: For complex gold ores, flotation technology can achieve a higher recovery rate, especially when used in combination with gravity separation, cyanidation and other methods, which can significantly improve the recovery effect.

(5) Iron ore: Although magnetic separation is usually used for the beneficiation of iron ore, in some cases, flotation can also be used to treat iron minerals such as hematite, especially when the ore contains other minerals that are easy to float.

The effect of flotation is affected by factors such as ore properties, mineral composition, mineral particle size and surface properties. By optimizing the selection of flotation agents, adjusting the pH value of the slurry, controlling the flotation time and bubble size and other operating conditions, the flotation efficiency and metal recovery rate can be further improved.

As a widely used beneficiation method, flotation has the following unique advantages:

Applicable to fine-grained materials: Flotation is particularly suitable for processing fine and micro-fine materials, which are difficult to recover by other beneficiation methods. Flotation can effectively separate micro-fine mineral particles less than 10μm from the slurry.

Economic rationality: Flotation is usually more economically rational because it can achieve better mineral processing results at a lower cost, especially when processing large quantities of ore. Flotation equipment has strong scale production capacity and low unit cost.

Flexible operability: During the flotation process, the type and dosage of reagents, pH value of the slurry, stirring intensity and other parameters can be adjusted to adapt to the characteristics of different minerals and achieve effective separation of minerals.

Wide range of applications: Flotation is not only used for the mineral processing of non-ferrous metals such as copper, zinc, lead, nickel, etc., but also for the mineral processing of ferrous metals, precious metals and non-metallic minerals, and even in the field of water purification.

High efficiency of sorting: Flotation uses the differences in the physical and chemical properties of the mineral surface to adsorb mineral particles through bubbles to achieve efficient sorting, which helps to improve the recovery rate of minerals and the quality of concentrates.

Although flotation has so many advantages, it also has some potential problems in terms of environmental protection, mainly including:

(1) Environmental pollution of flotation reagents: The reagents used in the flotation process, such as collectors and frothers, may contain harmful chemicals. Some of these substances remain in the tailings during the flotation process. If they are discharged directly without proper treatment, they will pollute the water and soil and affect the ecological balance.

(2) Heavy metal pollution: Flotation wastewater may contain high concentrations of heavy metal elements. These elements enter the water through precipitation, complexation and other effects, posing a threat to aquatic organisms and may affect human health through the food chain.

(3) Organic pollution: The organic agents used in the flotation process decompose under the action of microorganisms, which may consume a large amount of dissolved oxygen, causing water hypoxia and affecting the survival of aquatic organisms.

(4) Acid-base pollution: The acid-base medium used in the flotation process may change the pH value of the water body and have an adverse effect on the environment.

(5) Secondary pollution: If the flotation tailings are not handled properly, they may cause secondary pollution in the soil around the mining area, affecting soil quality and crop growth.

In order to solve these potential problems, a series of environmental protection measures need to be taken, such as improving the flotation process, using low-toxic and high-efficiency flotation reagents, implementing the recycling of tailings wastewater and clean production technology, and conducting risk assessment and remediation of the polluted areas around the mining area. These measures will help reduce the negative impact of flotation on the environment and achieve sustainable development of the mining industry.

In any case, given the many advantages of flotation, flotation has become one of the most widely used and most promising mineral processing methods.

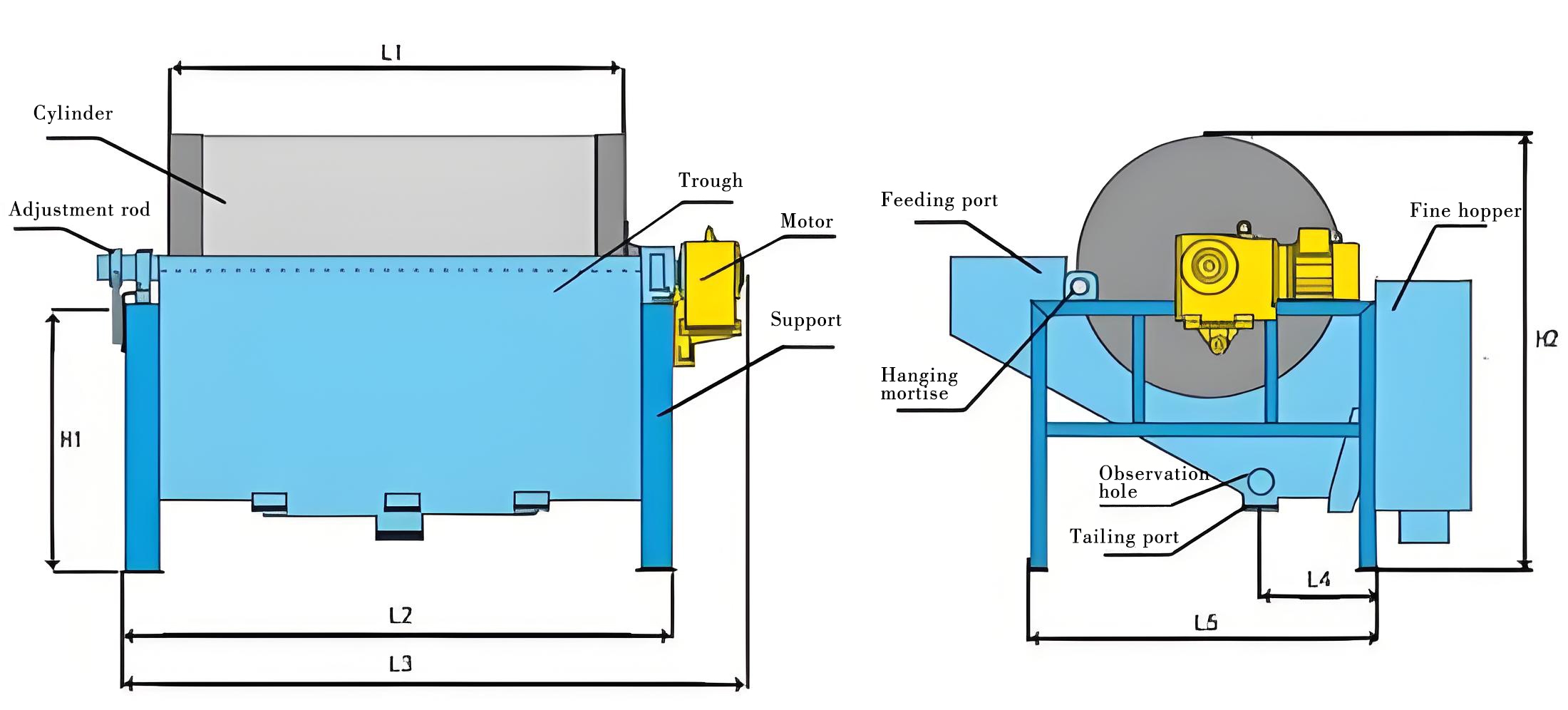

3. Magnetic Separation Method

Magnetic separation is a mineral separation method based on the magnetic difference of minerals. In this process, mineral particles pass through a magnetic field, and magnetic minerals are attracted by magnetic force and adsorbed to the magnet or magnetic medium, while non-magnetic minerals are not adsorbed, thereby achieving the separation of the two. Magnetic separation can be wet or dry, and the appropriate magnetic separation equipment and operating conditions are selected according to different mineral characteristics and processing requirements.

High efficiency of magnetic separation in processing specific ores

Magnetic separation shows high efficiency in processing ores with high iron content, especially those with obvious magnetism. For example, poor magnetite ore can be processed by weak magnetic separation, while hematite ore can be directly separated by a strong magnetic field magnetic separator even without magnetization roasting. In addition, manganese minerals and wolframite are also suitable for separation by strong magnetic field magnetic separators.

Application scenarios of magnetic separation method

Magnetic separation is not only widely used in the extraction of iron minerals, but also in the removal of impurities of non-metallic minerals, desulfurization of coal, and purification of wastewater and exhaust gas. The development of high gradient magnetic separators and superconducting magnetic separators has enabled magnetic separation to process minerals with finer particle sizes, expanding its application range in the field of mineral processing.

According to the latest information, the advancement of magnetic separation technology, such as the application of multi-layer induction magnetic pole magnetic separators, high gradient magnetic separators and superconducting magnetic separators, has enabled magnetic separation to more effectively process fine-grained and micro-fine-grained weakly magnetic minerals. The development of these technologies has brought new opportunities to the mineral processing industry.

The advantages of magnetic separation are mainly reflected in its efficient mineral processing ability and environmental friendliness:

Good separation: Magnetic separation can effectively achieve the selective separation of multi-element coexisting ores, improving the utilization rate and purity of minerals.

Simple process flow: The operation process of the magnetic separator is relatively simple, easy to realize automatic control, and reduces the difficulty of operation and labor costs.

Energy saving and emission reduction: During the operation of the magnetic separator, the energy utilization rate is high, and no chemical reagents are required, which will not pollute the environment, and it is in line with the modern concept of environmental protection and energy saving.

Stable equipment operation: The magnetic separator uses high-quality magnetic materials and advanced technology, which makes the equipment stable, long-life and low-maintenance.

The disadvantages of magnetic separation mainly involve its sensitivity to material properties and limited processing capacity:

Large equipment footprint: Magnetic separators usually require a large footprint, which may increase the investment cost and land use pressure of enterprises

Sensitive to material properties: Strong magnetic particles are prone to agglomeration or suspension during magnetic separation, which may affect the separation effect. In addition, magnetic separators also have certain requirements for the particle size, magnetic content, lubricity, etc. of the material, otherwise it will affect the magnetic separation effect and the stability of the equipment.

When processing non-magnetic minerals, the limitations of magnetic separation are mainly reflected in the following aspects:

Low separation efficiency: Since non-magnetic minerals themselves are not magnetic, they will not be directly attracted by the magnetic field. Therefore, the separation efficiency of magnetic separation when processing non-magnetic minerals is usually not as high as when processing magnetic minerals.

Limited applicability: Magnetic separation is suitable for minerals containing magnetic impurities. For those minerals that do not contain magnetism or have very weak magnetism, the effect of magnetic separation is not good and may need to be used in conjunction with other mineral processing methods.

Equipment cost: Although the operating cost of magnetic separation equipment may be relatively low, its initial investment cost is high, which may be a limiting factor for some small mines or projects with limited economic conditions.

Sensitive to ore properties: Magnetic separation is very sensitive to the physical and chemical properties of the ore. Different ores require different types of magnetic separation equipment and operating conditions, which increases the complexity of the process and the difficulty of optimization.

Limited product particle size: Magnetic separators are mainly suitable for finer magnetic particles. For materials with larger particle sizes, their separation effect may be limited to a certain extent.

Strategies for optimizing magnetic separation processes

Adjust the magnetic field strength: Adjust the magnetic field strength according to the magnetic strength and particle size of the material to improve the recovery rate of magnetic minerals.

Optimize magnetic separation equipment: Select appropriate magnetic separation equipment, such as permanent magnetic separators or high gradient magnetic separators, to accommodate materials with different particle size ranges.

Improve magnetic separation parameters: Adjust parameters such as slurry flow rate and magnetic separation time to optimize the magnetic separation effect.

Grading magnetic separation technology: Divide the material into coarse and fine particles, and perform magnetic separation separately to improve the overall recovery rate and reduce energy consumption.

Multi-stage magnetic separation process: The magnetic separation process is divided into roughing, concentrating and scavenging stages to improve the quality of concentrate and resource recovery rate.

According to the above description, in actual operation, mining companies should decide whether to use magnetic separation or combine it with other beneficiation methods according to the specific ore characteristics and economic conditions. When implementing optimization measures, adjustments should also be made in combination with specific production conditions to ensure the scientificity and effectiveness of the process flow.

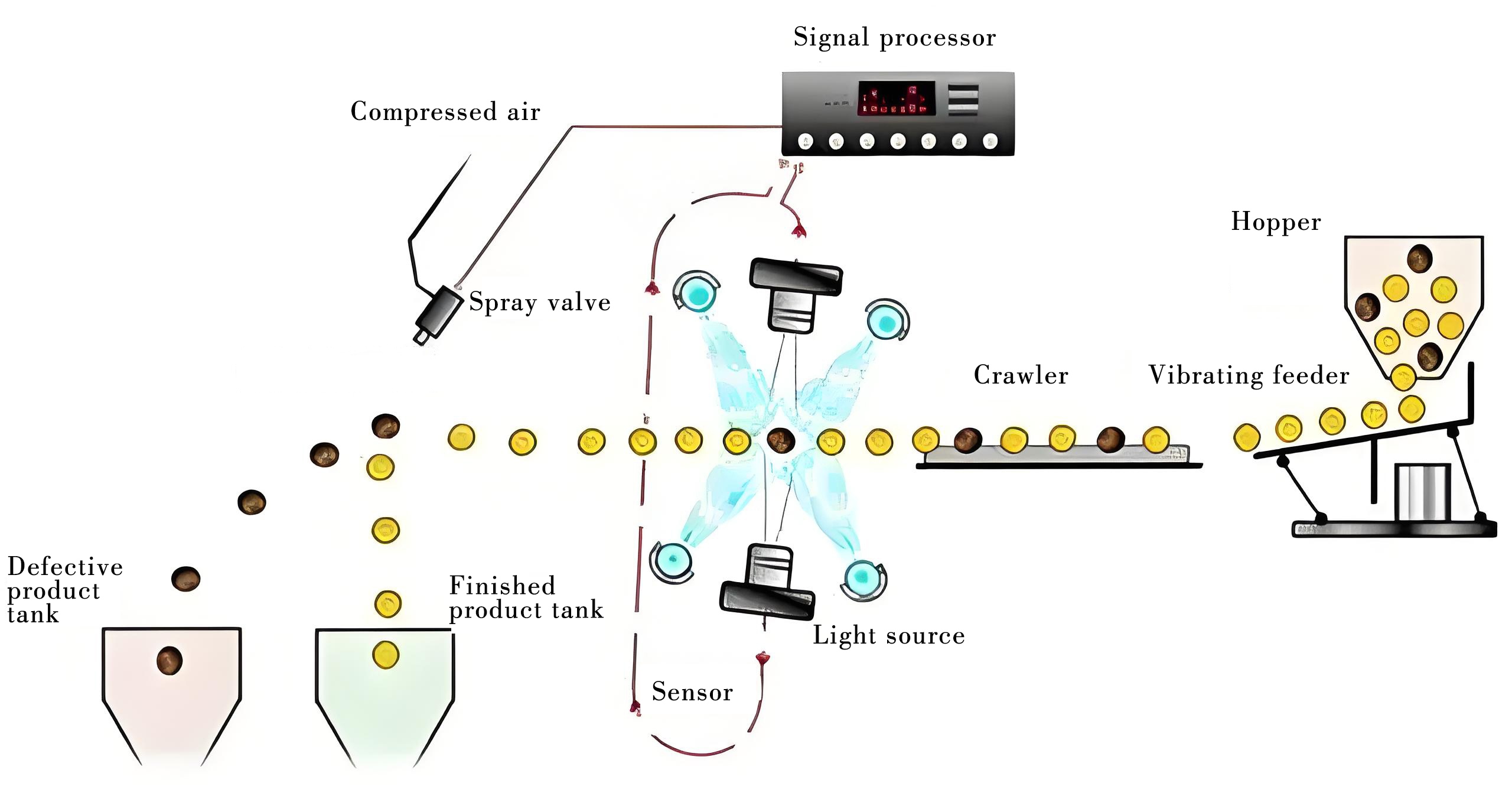

4. Photoelectric Separation

The photoelectric separation method is used to separate ores by detecting the optical properties of the ore (such as color, gloss, etc.). This method is efficient, energy-saving and environmentally friendly, and is suitable for quickly removing a large amount of useless gangue and improving separation efficiency.

Scope of application of photoelectric ore separation

Photoelectric ore separation technology is suitable for pre-sorting and enrichment of various ores, especially in the processing of non-ferrous and precious metal ores. It can achieve precise separation of minerals based on the optical properties of the ore, such as color, gloss and transparency. Photoelectric sorting technology has shown significant advantages in processing low-grade phosphate resources. It can quickly remove useless gangue, reduce the pressure of subsequent mineral processing links, and make the phosphate resources that were originally difficult to develop and utilize economically and effectively be fully recycled.

Advantages and disadvantages of photoelectric ore sorting

advantages:

High efficiency: Photoelectric sorting technology can quickly remove a large amount of useless gangue and improve sorting efficiency.

Low cost: Compared with traditional physical and chemical mineral processing, the only energy consumption of photoelectric sorting is electricity consumption, and the cost of mineral processing per ton is low.

Green and environmental protection: Photoelectric sorting has zero pollution to the environment and is a greener mineral processing method.

Technological progress: With the development of computer technology and artificial intelligence technology, the intelligence level of photoelectric sorting equipment has been continuously improved, which can better adapt to the sorting needs of different types and complex ore structures.

Strong adaptability: By introducing cutting-edge technologies such as artificial intelligence and big data analysis, the intelligence level and adaptability of the photoelectric sorting system have been greatly improved, and it can process more types of ores.

Disadvantages

Technology dependence: The high performance of photoelectric sorting technology depends on advanced sensors and algorithms, and has high technical requirements for operators.

Equipment cost: Although the operating cost is low, the initial investment of photoelectric sorting equipment is high, which may limit its application in small or cost-sensitive projects.

The advantages of photoelectric ore sorting technology are its high efficiency, low cost and environmental friendliness, while the disadvantages are mainly concentrated in technical expertise and equipment cost. In practical applications, the choice of whether to use photoelectric sorting technology should be based on the specific ore characteristics and economic considerations.

Taking phosphate ore sorting as an example, photoelectric ore sorting technology is mainly based on the differences in optical properties between phosphate ore and its associated minerals, such as color, gloss and transparency, and achieves accurate separation of phosphate ore through specific light source illumination and precise identification of photoelectric sensors. This technology can quickly remove a large amount of useless gangue, so that phosphate resources that were originally difficult to develop and utilize economically and efficiently can be fully recycled.

The specific impact of photoelectric ore sorting on the recycling of low-grade phosphate ore

Improve resource utilization: Photoelectric ore sorting technology can significantly improve the original ore grade of low-grade phosphate ore, making it more economically valuable for mining. For example, in the application of Yichang Baoshishan phosphate mine, even under the condition of 14%-16% P2O5 grade of the raw ore, the P2O5 grade of the concentrate can reach more than 25%.

Reduce production costs: By quickly removing useless gangue, photoelectric sorting reduces the pressure of subsequent beneficiation links, improves production efficiency, and reduces production costs. For example, the actual operation of Shanshuya Photoelectric Concentrator in Yiling District shows that the direct cost of photoelectric beneficiation is about 5 yuan/ton, which is much lower than the cost of heavy medium beneficiation.

Reduce environmental pollution: Photoelectric sorting technology does not involve traditional pre-wetting, de-medium magnetic separation, concentration, filter pressing, dehydration and other links, does not generate wastewater, and the sludge treatment is simple, safe and environmentally friendly.

Improve the quality of phosphate concentrate: Photoelectric sorting technology can improve the P2O5 recovery rate and grade of phosphate concentrate. For example, in the application of Yichang phosphate mine in Hubei, the P2O5 recovery rate of concentrate is above 88% on average, which is much higher than the previous 72% indicator.

Promote efficient and high-value utilization of resources: The application of photoelectric sorting technology helps to achieve the coordinated development of phosphorus resource development and protection, and is in line with the relevant national energy conservation and emission reduction and carbon peak and carbon neutrality target policies.

Since its establishment in 2014, MINGDE Optoelectronics Technology Co., Ltd. has been focusing on photoelectric sorting. Its mineral color sorters and AI mineral sorters have good market performance and have been proven in practice in various ore sorting.

Today we will first introduce these four more common ore sorting methods, and there are four more emerging ore sorting methods later, which we will continue to introduce tomorrow.