What are the mainstream operation methods for mine rehabilitation?

Aug 05, 2023

What are the mainstream operation methods for mine rehabilitation?

Aug 05, 2023

What are the mainstream operation methods for mine rehabilitation?

Mining development accompanies the whole process of human civilization, social progress, and scientific and technological development, and is a basic industry of the country. When the development of mineral resources enters the decline period, mines will face closure, ushering in the final stage of mining engineering services. The decline and closure of a mine may be due to resource depletion, unsatisfactory economic benefits, technical difficulties, unsecured mining and production safety, and government policy orientation. In the past, China has adopted the model of closing first and then managing the mines facing closure, and certain problems have arisen as a result. This model, has gradually can not adapt to the needs of social development.

(The restored Zhalainuoer open-pit mine in Inner Mongolia in 2020)

In 2007, China put forward the initiative of "developing green mining" at the International Mining Conference; in 2009, the National Development and Reform Commission (NDRC) and the Ministry of Land and Resources (MLR) jointly issued the "National Mineral Resources Plan (2008-2015)", which explicitly put forward the requirement of developing green mining; in 2010, the MLR issued the "National Mineral Resources Plan (2008-2015)", which was a joint effort of the NDRC and the MLR to implement the National Mineral Resources Plan. Ministry of Land and Resources on the implementation of the national mineral resources planning development of green mining construction of green mines work guidance", accompanied by the "basic conditions of the national green mines", clearly put forward the "mining, reclamation", the mine suppression, damage and reclamation of land should be fully restored, but also put forward the development of mine It also proposes the formulation of mine environmental protection and governance and restoration programs, with clear objectives and appropriate measures. These few things, laid the foundation of China's mine restoration business.

(In 2018, Huayuan County, Hunan Province, has re-greened the land cover of Unity Mine, with initial success)

Outside of China, land reclamation, ecological restoration and landscape reconstruction of mines have been emphasized by various countries. After years of research and practice, a lot of restoration experience has been accumulated worldwide that can be drawn upon, and it is well worthwhile for China to study and learn from.

According to different functions and characteristics, there are seven main modes of mine restoration, including ecological restoration, utilization of museum resources, tourism development, reclamation of land, diversion of water to create lakes, waste treatment plants and storage.

01. Ecological restoration category

From the perspective of ecology, mines are complex ecosystems composed of subsystems such as resources, environment, economy and society. Mining ecological problems almost go hand in hand with mining development, especially with the rapid development of the economy, years of uncontrolled mining will inevitably cause some damage to the environment, resulting into soil stripping, rock debris and low-grade ore accumulation formation, empty mining area and subsidence area formation, tailings accumulation formation, the impact of mining and can not be utilized for the development of the land and other issues, so that its ecological environment is seriously deviated from the natural state.

(Ecological restoration is a very complex project, according to local conditions, to select the most appropriate restoration method line)

Therefore, mine ecological restoration is mainly to accelerate the process of ecological succession by eliminating disturbances and accelerating the changes of biological components, so that the degraded ecosystem can be restored to a certain ideal state. In this process, people not only need to use plants, soil microorganisms and soil animals to help improve the physical and chemical properties of the soil, but also according to the planning, selecting appropriate and vegetation species for ecological restoration. In this process, measures to stabilize slopes, such as removing dangerous rocks, lowering slopes and cutting slopes, and constituting cliffs that have not formed steps into horizontal steps as much as possible, are very important.

Of course, it is very difficult for a mine to be completely or basically restored to its original state before development. However, ecological restoration can help mines form new vegetation or ecosystems. Among them, restoration to grassland, forest or farmland is more common.

02. Utilization of Museum Resources

The use of museum resources refers to the excavation, collation and study of the history of the development and construction of mines around the world, the protection and scientific use of mining relics and geological relics, mine environmental protection and restoration of governance, and the exploration of the road of sustainable development of resource-exhausted mines. IMG_259 (Anhui Huaibei National Mining Park)

Anhui Huaibei National Mining Park belongs to this category. Huaibei National Mining Park was declared by the organization in 2005, and the construction was approved by the state in August 2005, passed the expert review in July 2007, and in October 2007, the groundbreaking took place. The completed Huaibei National Mining Park covers an area of about 40 acres, with a construction area of 3,642 square meters and a total of 12 exhibition halls, namely, Prologue Hall, Multimedia Demonstration Hall, Roadway Simulation Hall, Comprehensive Hall, Mining Safety Hall, Coal Resource Utilization and Industry Chain Hall, Enterprise Style Hall, Coal and Huaibei Prologue Hall, Coal and Huaibei Main Exhibition Hall, City is the Park Hall, Message Wall Hall, as well as the Recreation and Experience Hall. The Huaibei National Mining Park is modeled after the Youyi Coal Mine, showing a dynamic coal mine to people.

The Huaibei National Mining Park in Anhui Province belongs to this category. Huaibei National Mining Park was declared by the organization in 2005, approved by the state in August 2005, passed the expert review in July 2007, and in October 2007, the groundbreaking took place. The completed Huaibei National Mining Park covers an area of about 40 acres, with a construction area of 3,642 square meters and a total of 12 exhibition halls, namely, Prologue Hall, Multimedia Demonstration Hall, Tunnel Simulation Hall, Comprehensive Hall, Mining Safety Hall, Coal Resource Utilization and Industry Chain Hall, Enterprise Style Hall, Coal and Huaibei Prologue Hall, Coal and Huaibei Main Exhibition Hall, City is the Park Hall, Message Wall Hall, as well as the Recreation and Experience Hall. The Huaibei National Mining Park is modeled after the Youyi Coal Mine, showing people a dynamic coal mine in its original form. It traces the production and discovery of coal, explores the early development of coal in Huaibei, recounts the history of the revolutionary struggle of miners in Huaibei, and concentrates on the history and culture of the mining industry in Huaibei and the knowledge of geological science and technology, as well as the road of the rise, transformation and leaping of the city of Huaibei, whose core exhibits consist of the physical equipment of the construction of mines as well as the related text, pictures and video materials, with an exhibition area of 3,000 square meters, 36 sets of electronic equipment, 973 pieces of ore specimens, 973 pieces of mineral specimens and 973 pieces of mineral specimens, and the video materials of the city of Huaibei. The exhibition area is 3,000 square meters, with 36 sets of electronic equipment, 973 pieces of ore specimens and more than 200 pieces of physical objects.

03. Tourism Development

With the environmental problems becoming more and more prominent, the national macro-policy on mining activities to carry out strict control, and gradually outlawed shutdown. Under such a general trend, numerous mining enterprises are under pressure to shut down or transform. Therefore, in December 2015, the Ministry of Land and Resources, the Ministry of Housing and Urban-Rural Development, and the National Tourism Administration jointly issued the Opinions on Land Use Policies for Supporting the Development of Tourism, a document that clearly proposes to support the use of unutilized land, abandoned land, abandoned mines, and remote islands for the construction of tourism projects. Clarify the land use policy for new tourism business, promote cultural development, and use existing cultural heritage, large public facilities, famous colleges and universities, scientific research institutions, industrial and mining enterprises, and large farms to carry out cultural and study tourism activities, etc. Under the premise of conforming to the planning and not changing the use of the land, the land right holders of the above institutions who use their existing properties to set up lodging, catering, and other tourism reception facilities can keep the original land use and right types unchanged. The new land policy encourages the development of tourism on abandoned industrial and mining land, giving a strong boost to tourism development in mines.

(Interface of the document "Opinions on the Policy of Supporting Land Use for Tourism Development" on the government's official website)

Objectively speaking, tourism development of mines not only has the opportunity to realize more significant economic benefits, but also can solve the problem of releasing a large number of laborers in mining areas who are in urgent need of employment and resettlement. In addition, tourism, as an industry strongly advocated and supported by the state, can also strive for more policy support and financial support for mine restoration, and ultimately realize the goal of ecological, economic and social benefits at the same time.

Mine tourism development has been a long time, but mostly for the mine shut down through the development of ecological restoration and governance, the more successful cases are the British Eden, the project can be regarded as the world's largest greenhouse. The project site was originally a huge pit left behind by the local people extracting clay, the project investment of 130 million pounds, lasted two years, completed in 2000. The project mainly consists of eight futuristic colors full of huge honeycomb dome building, which every four dome-shaped building connected to a group, in the form of a blister like an enlarged countless times. Tens of thousands of species of plants native to Africa, Asia, Europe, Oceania and the Americas in different climates are cultivated in the "Big Bubble", with the main purpose of demonstrating the relationship between plants and people, and how human beings rely on plants for sustainable development. It attracts more than 1.2 million visitors from all over the world every year.

(Garden of Eden)

A better developed case in China is the Huangshi National Mining Park. Located in the Tieshan District of Huangshi City, Hubei Province, Huangshi National Mining Park is the first national mining park in China. The famous Han Ye Ping Coal and Iron Company's "metallurgy" refers to Daye Iron Mine. After a hundred years of mining, the East Open Pit of Daye Iron Mine has formed the world's high and steep slopes with a drop of 444 meters. In order to manage the ecological environment, the mine invested tens of millions of dollars to form a hard rock reclamation base in Asia. in July 2006, the Daye iron ore mine area, Tonglushan ancient copper mine site area composed of "a park and two areas", by the National Mining Park Review Committee review and approval, confirmed as the Huangshi National Mining Park, the planning area of 30 square kilometers.

(Huangshi National Mining Park)

04. Reclamation of land

The research and implementation of reclamation and field-building technology has a history of several decades in Europe and the United States. The model is to improve the local geological conditions, supplement and increase the area of arable land by reclaiming the mines after development, which has better economic and social benefits.

(Da Manzi Mountain Comprehensive Land Improvement Project)

Laiwu District, Miao Shan Township, Da Manzi Mountain Land Comprehensive Improvement Project belongs to this category, in order to completely eliminate hidden dangers, accelerate the progress of abandoned mine governance, natural resources departments of the project for mining geological environment restoration and governance, reclamation of industrial and mining wasteland, land upgrading and renovation of the three phases of governance. The sand and gravel plant, which was reclaimed in an unorganized manner and damaged the ecology seriously, was transformed into farmland, with a total governance area of more than 760 acres, a total investment of more than 35 million yuan, and 360 acres of new arable land. The project started in June 2018, and has now basically reached the conditions for completion and acceptance.

05. Water diversion and lake-making

The water diversion and lake-making project can be said to be an extension of the reclamation and field-making project, and through the systematic governance and reconstruction of the environment and ecology around the mining pit, water can be introduced to transform the open pit into a lake. Through the role of the lake, the land near the pit will be slowly transformed into fertile farmland, dense forests and blue lakes, which can realize the integrated development of the mining area's economy, culture, tourism and society.

(Biville Quarry, France)

The most famous case is the Biville Quarry in France, located at the top of the Clairefontaine gorge, which was shut down in 1989 after 10 years of stone extraction. What was left was a 450m long linear quarry pit of uniform width, uneven due to the 20-40m drop and the barren 45-degree slopes. The designers transformed it into a recreational area with a 3.5 square kilometer lake, including a series of facilities and equipment designed to direct the flow of water so that it would converge to form a lake on the valley floor. The banks of the lake were designed to accommodate the most popular leisure activity in the area - fishing. Vegetation was then introduced to restore the abandoned quarry to a natural state, and the Biville quarry was transformed to preserve the industrial aspects of the site and to transform it into a distinctive and iconic place in the new landscape structure, showing respect for the historical heritage of the site.

06. Waste treatment plant

With the development of the mining industry, the problem of "garbage around the mountain" is also highlighted. In the past, the waste residue and garbage produced in the process of mining were casually discharged and discarded, which can easily lead to water pollution and land contamination over time. The use of abandoned mine pits as a production and living garbage treatment base, can solve the problem of garbage occupation, environmental pollution, resource recycling and reuse, get three good results in one.

(St. Michaels Environmental Center)

In Montreal, Canada, there is a waste treatment plant built using a mine pit - St. Michel Environmental Center. 1930s, this land in the downtown area of Montreal, a large limestone mining site about 70 meters deep. 1968, the local people stopped logging, but used a lazy way --In 1968, the locals stopped logging, but in a lazy attempt to heal the earth's "bleeding scars" by filling it with landfill. Soon the site became the third largest landfill in North America, and the residents of the 57 surrounding communities began decades of nightmares about the stench, the annoying crows, the noise of garbage trucks, and the possibility of groundwater contamination by seepage from the landfill. 1984 saw the City of Montreal decide to reclaim the land, 1988 saw a halt to the quarrying process, and 1995 saw the beginning of a massive revitalization process. Today, the site is being transformed into a large park and green space that has been given a new lease of life and will be fully open to the public in 2020. Under the guidance of the government, the project was constructed as a comprehensive final waste disposal site. The initial renovation of the project was aimed at the methane gas from the decomposition of the waste, and thus a power plant to convert the methane gas into electricity was built, and after the environment was greatly improved, a wastewater treatment system was built to efficiently collect the waste waste liquids, so that the waste pollution was reduced to a minimum. In the course of the management process, the city government has a more positive vision for the future of the project, not only to restore the damaged soil and cultivate a large forested green space, making it the largest green park in the city, but also to build facilities for education, leisure and cultural activities, and, at the same time, to preserve the mining history of the area. ...... In the joint efforts of the people, the San Michele Environmental Center has become the most important environmental center in the city, and the city's environmental policy has become the most important one. Working together, the St. Michaels Environmental Center was reborn.

07. Warehousing

Some of the abandoned mines can be transformed into warehouses for the development of side industries by utilizing their geographical and topographical features. Firstly, some abandoned mines with stable surrounding rocks, relatively spacious roadways, suitable for automobile traffic and relatively convenient transportation can make use of their characteristics of warm winters and cool summers, and through engineering renovation can be turned into warehousing sites for storing fruits, vegetables and other items that need to be stored within a certain temperature range. Secondly, abandoned mines with stable surrounding rocks, with roadways that are easy to transport, far away from villages, and that are not water sources or with developed water systems, especially abandoned mines with large distances from the surface of the air-mining zone, can be used as storage sites for waste materials from industrial and medical industries after renovation. Finally, some mines are not far from towns and are not located upstream of water sources or upwind of towns, and abandoned open-pit mines and underground mining subsidence zones that are larger in scale and lower than the surrounding terrain can be used as landfill sites for town waste.

--------------------------------------

Note: This article comes from Mining State, Mining Safety World.

Tailings problem, gold companies to solve this way ......

Jun 29, 2023

Tailings problem, gold companies to solve this way ......

Jun 29, 2023

The requirements of different mineral species for drilling!

Jul 05, 2023

The requirements of different mineral species for drilling!

Jul 05, 2023

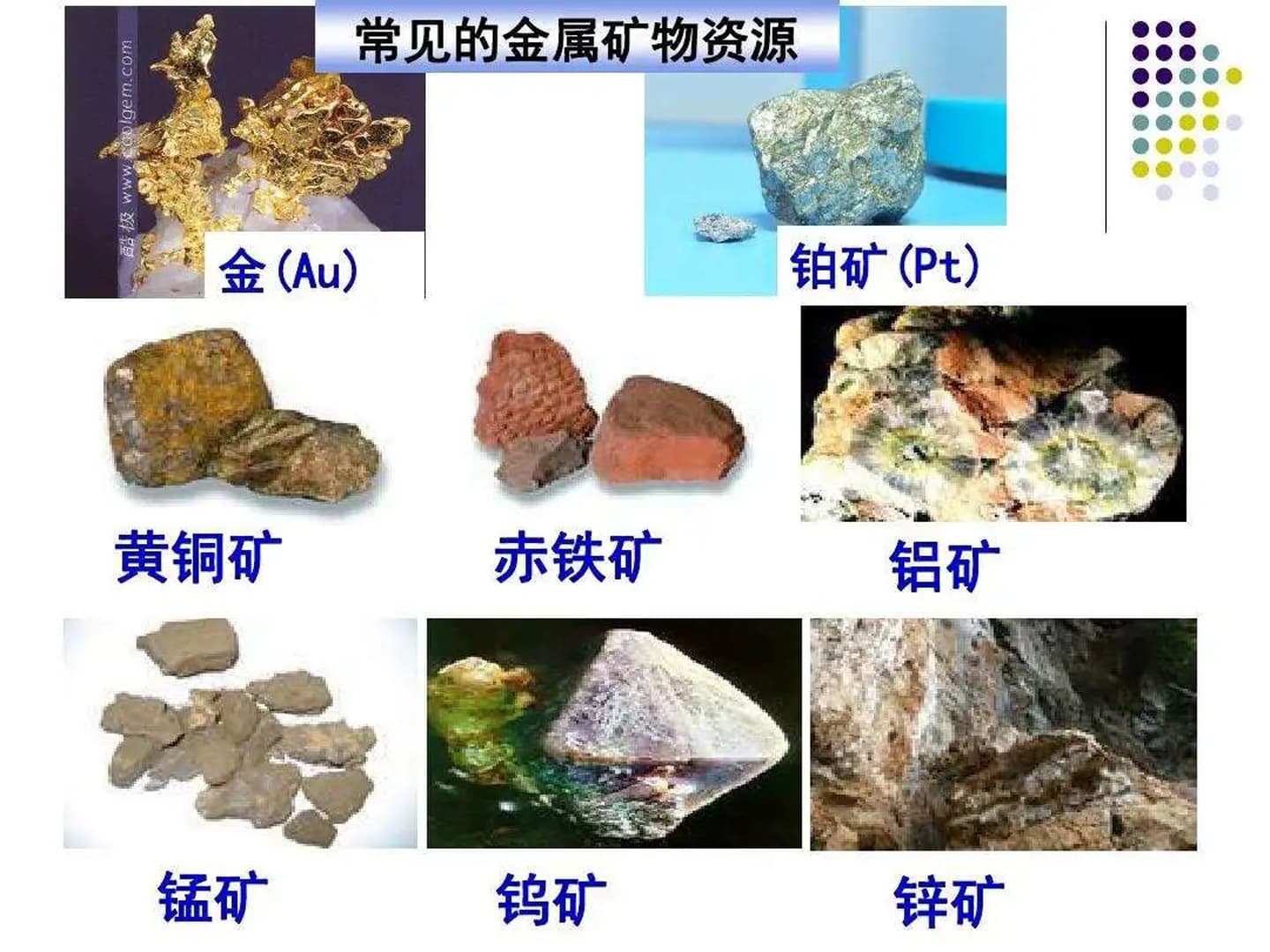

Distribution of metal mines in China (mineral resources profile)

Jul 07, 2023

Distribution of metal mines in China (mineral resources profile)

Jul 07, 2023

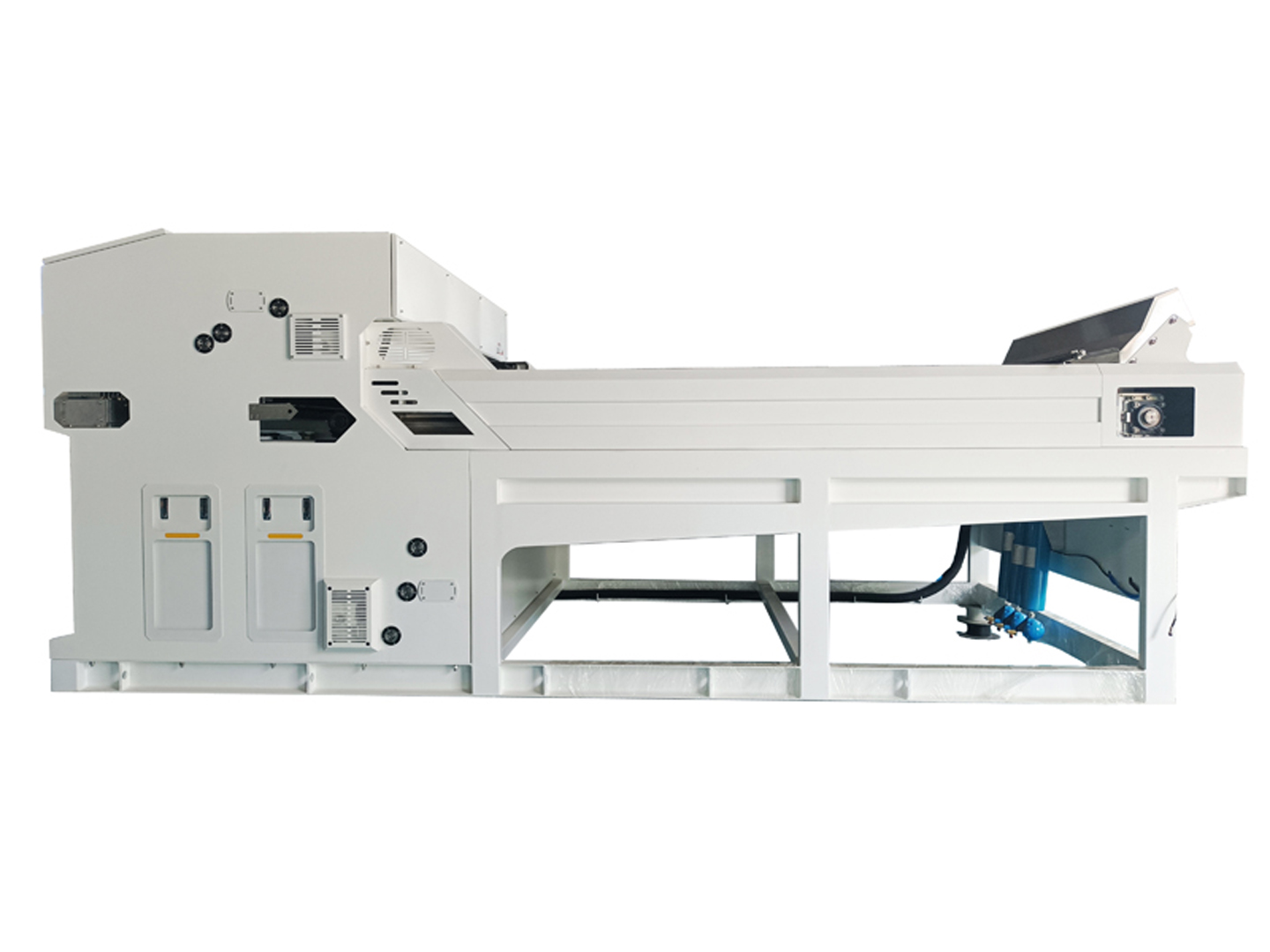

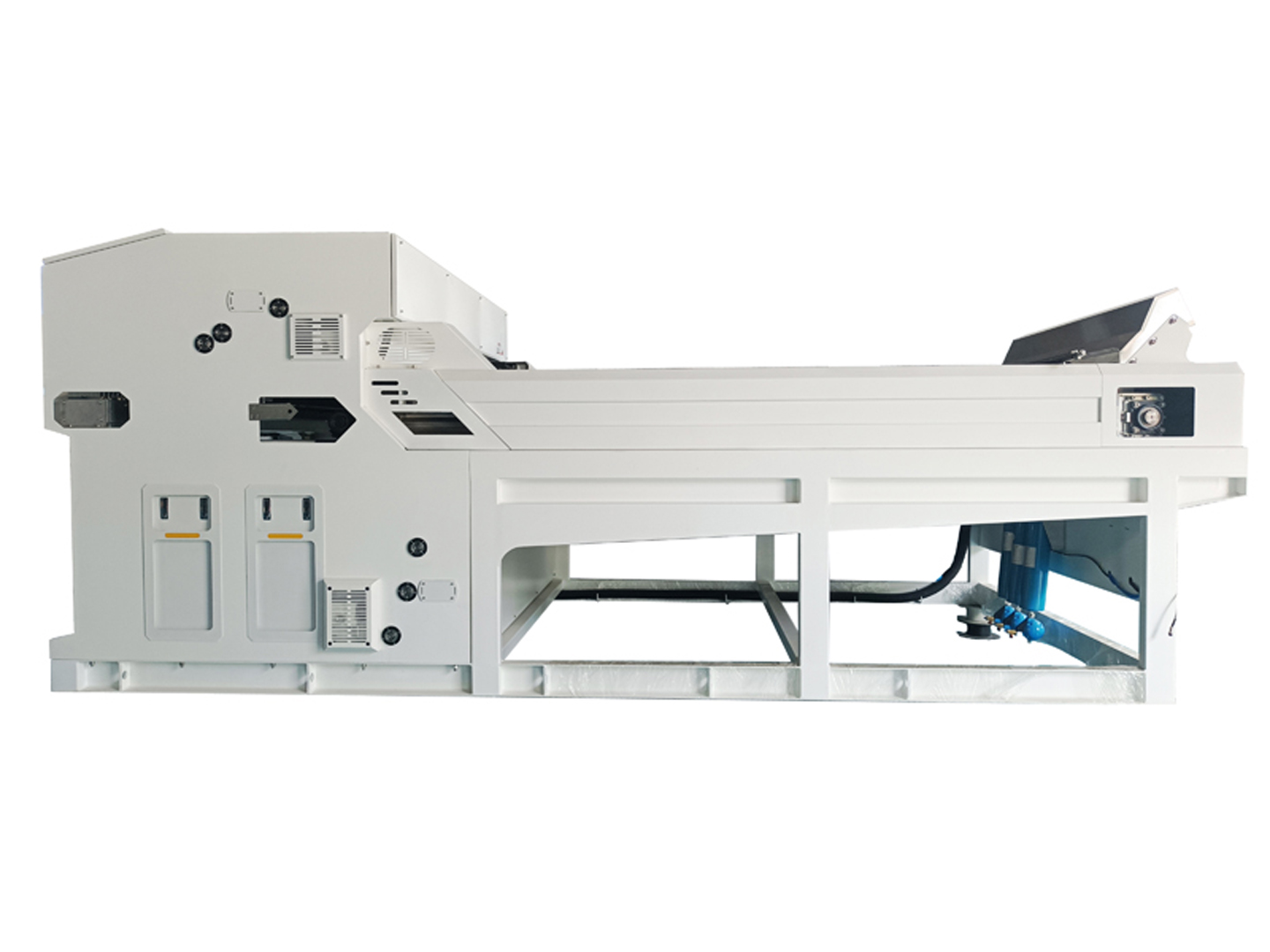

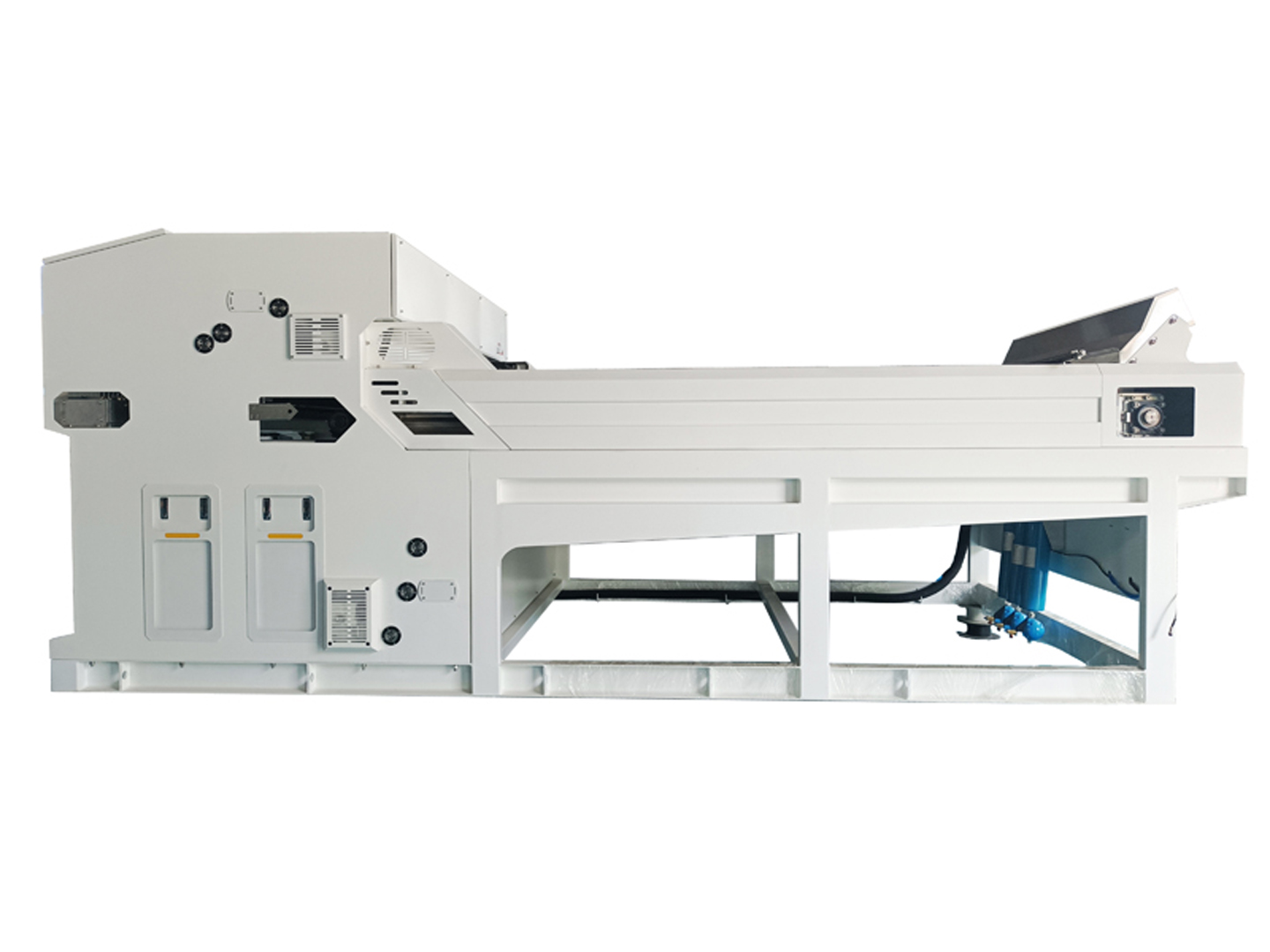

Mobile, semi-mobile, semi-fixed, fixed 4 types of crushing plant detailed introduction and comparison of advantages and disadvantages

Jul 08, 2023

Mobile, semi-mobile, semi-fixed, fixed 4 types of crushing plant detailed introduction and comparison of advantages and disadvantages

Jul 08, 2023

What is the difference between river sand, mechanism sand, washed sand, recycled aggregate, and tailings sand?

Jul 11, 2023

What is the difference between river sand, mechanism sand, washed sand, recycled aggregate, and tailings sand?

Jul 11, 2023

A few changes in the direction of our mining policy

Jul 24, 2023

A few changes in the direction of our mining policy

Jul 24, 2023

What are the mainstream operation methods for mine rehabilitation?

Aug 05, 2023

What are the mainstream operation methods for mine rehabilitation?

Aug 05, 2023