Lead zinc ore sorting technology - improve efficiency and reduce cost!

Oct 22, 2022

Lead zinc ore sorting technology - improve efficiency and reduce cost!

Oct 22, 2022

Lead zinc ore refers to the mineral resources rich in metal elements lead and zinc. In nature, lead and zinc often coexist, and are also associated with other metal ores and gangue ores. The metal ores mainly include brass, pyrite, etc. The gangue ores mainly include quartz, calcite, fluorite, barite, dolomite, etc. According to oxidation, it can be divided into oxidized ores and sulfide ores. Because lead-zinc ores have strong sulfur affinity, most lead-zinc ores in nature are sulfide ores. The main application fields are machinery, military, metallurgy, chemistry and medicine.

The domestic lead and zinc mineral resources are relatively rich, which are characterized by wide distribution and high concentration of mineral resources in 27 provinces, cities and districts in China. From the perspective of enrichment and existing reserves, China's lead and zinc ores are mainly distributed in Inner Mongolia, Gansu, Hunan, Yunnan, Guangxi and Guangdong, accounting for 64% of the national lead and zinc ore reserves; Large and medium-sized deposit stations have high reserves and complex ore types. The reserves of lead and zinc in large and medium-sized deposits account for 72% and 88.4% respectively. There are few single type lead or zinc ores, and the ore types are relatively complex, mainly including lead zinc ores, lead zinc copper ores, lead tin ores, lead antimony ores, etc; There are many poor ores, few rich ores and few easy beneficiation. According to statistics, the domestic lead and zinc ores are mostly of 5% - 10% grade, and those with a grade higher than 10% only account for 15% of the total storage, while the foreign lead and zinc ores have a higher overall grade, most of which are more than 10%. The types of lead-zinc deposits in China mainly include granite type, skarn type, porphyry type, marine volcanic rock type, continental volcanic rock type, carbonate rock type, mudstone fine clastic rock type and glutenite type.

In terms of beneficiation process, the lead-zinc ore is mainly flotation, and gravity concentration is also used. At the same time, the internal distribution of lead-zinc ore is uneven. There are different separation processes for each ore.

The common separation processes of lead-zinc ores in China mainly include preferential flotation, mixed flotation, full mixed flotation, heavy medium pre separation, heavy medium pre separation flotation gravity separation combination, etc. floatable flotation and asynchronous mixed flotation.

The above sorting methods of lead and zinc ores belong to conventional traditional separation methods, but at present, China's lead and zinc industry is mainly faced with several problems. The contradiction between industrial sustainable development and ecological environment protection is mainly reflected in China's long-term high demand for lead and zinc ores, driving the rapid development of lead and zinc industry, causing certain impact and damage to the ecological environment, and the low comprehensive utilization of lead and zinc resources, Especially in the aspect of valuable associated gangue, at the same time, strict prevention of heavy metal pollution has become an insurmountable red line in the lead and zinc industry. The way of scale, volume and extensive development in the lead and zinc industry has not met the development needs at this stage. At this stage, it is necessary to change to a circular, low-carbon and green direction. Another important reason is that the production cost of lead-zinc ore has risen and the product price has fallen, and the cost rigidity has risen - the equipment has low operating rate - the supply is relatively surplus - the price has low volatility - the benefit has been marginalized ".

At the present stage, the requirements for lead and zinc ore mining and beneficiation are to meet the needs of social development, improve the comprehensive utilization of resources, reduce production costs. Green and sustainable development is the new trend of the industry, especially in the continuous use of lead and zinc beneficiation process, which is obvious. For some lead and zinc ore beneficiation stages, we can fully take measures to increase the economic benefits of the mine, save the beneficiation cost and reduce the tailings disposal capacity, It also meets the development needs of green mines.

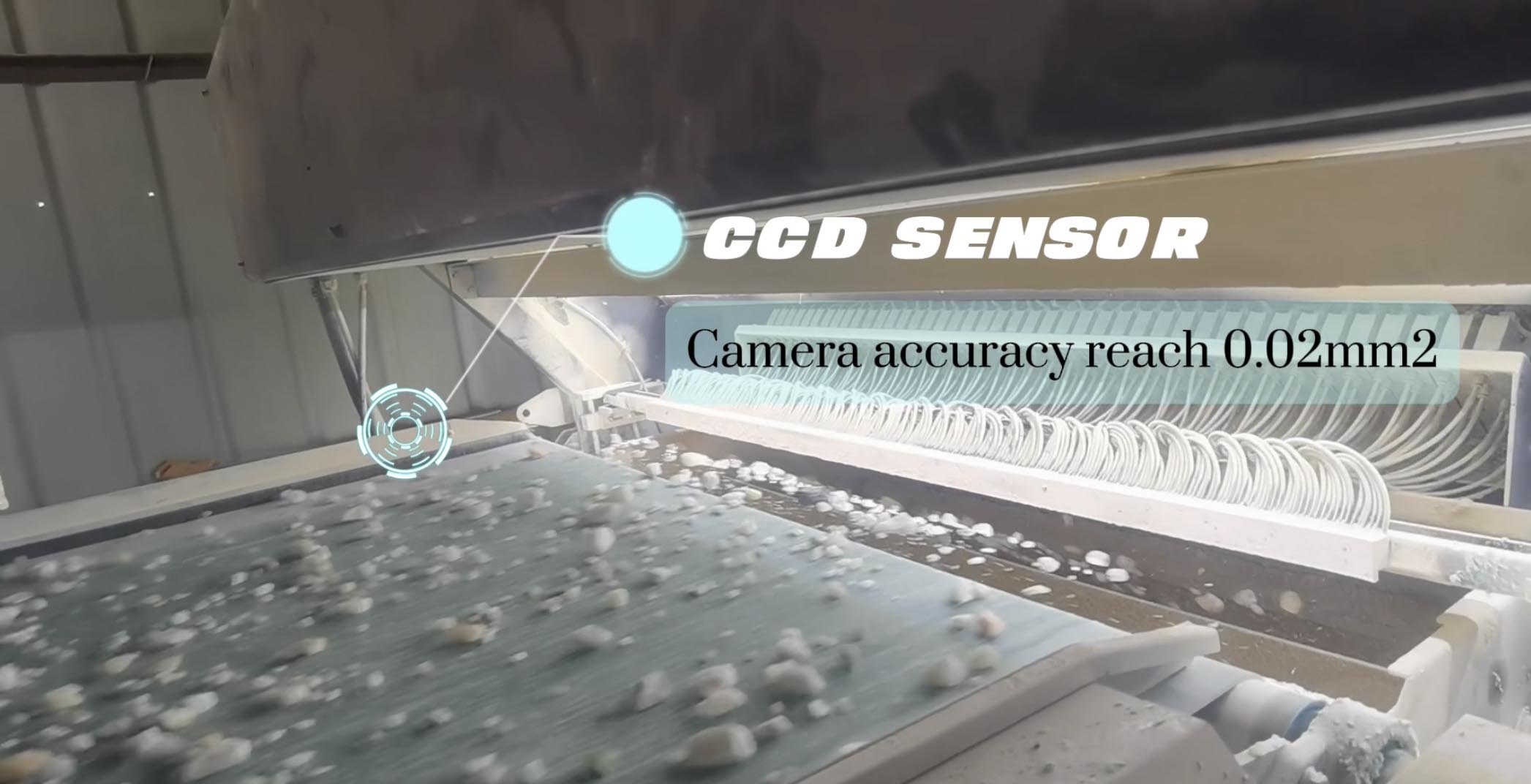

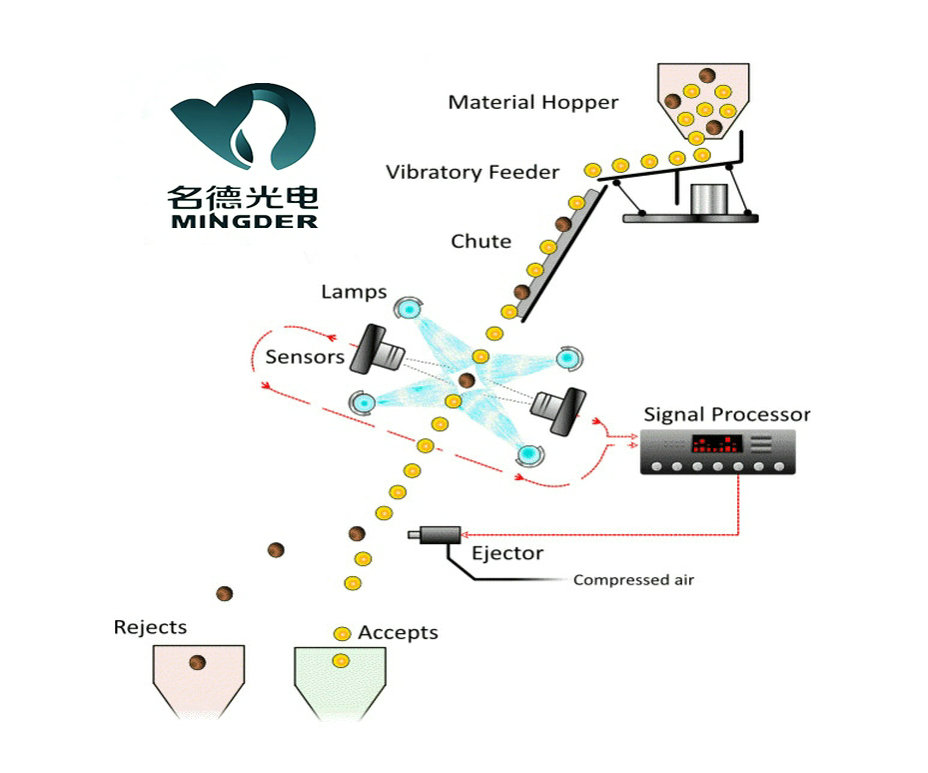

The main plan is to enrich the grade of lead-zinc ore in advance, pre dispose the waste tailings, and reduce the processing capacity of grinding flotation raw ore, mainly using the photoelectric separation equipment ore separator. There are mainly two types of ore separation equipment suitable for the separation of lead and zinc ores. One is the Mingde Optoelectronics artificial intelligent ore separator, which establishes a multidimensional three-dimensional model of ores through the surface characteristics difference after the lead and zinc ores are broken and separated, and identifies the good and bad materials, so as to achieve the purpose of grade enrichment. For example, lead and zinc barite, lead and zinc fluorite ores, etc., the expected beneficiation effect can be achieved through the artificial intelligent ore separator. The second one is X-ray intelligent ore separator, which mainly uses X-ray to project lead-zinc ore and identify the good and bad materials according to the difference of ore density, so as to achieve the purpose of enrichment. The above two ore separators can meet the development needs of the lead-zinc industry at this stage.

Among them, Mingde Optoelectronics focuses on the field of ore separation and digital color separating machine. It has accumulated rich experience and technology in ore photoelectric separation and precipitation. The four series of products designed and produced not only have a development prospect in the lead and zinc industry, but also have a large application space in other ore separation and beneficiation fields. At this stage, the application scope covers the metal and non-metallic fields, such as fluorite, talc, quartzite, barite, K-feldspar, calcium carbonate, magnesite, gold mine There are nearly 100 kinds of ores such as high crystal silicon, copper, iron, vanadium, phosphate rock, coal and gangue.

How to effectively separate feldspar and fine grain quartz?

Jan 13, 2024

How to effectively separate feldspar and fine grain quartz?

Jan 13, 2024

How to separate calcium carbonate with optical ore color sorting machine?

Jan 12, 2024

How to separate calcium carbonate with optical ore color sorting machine?

Jan 12, 2024

What are the techniques used in ore sorting?

Dec 23, 2023

What are the techniques used in ore sorting?

Dec 23, 2023

What is the process of mineral sorting?

Dec 22, 2023

What is the process of mineral sorting?

Dec 22, 2023

Working Principle of Ore Color Sorter

Nov 24, 2023

Working Principle of Ore Color Sorter

Nov 24, 2023

Enhancing Mining Productivity: The Advantage of Optical Ore Sorting

Nov 23, 2023

Enhancing Mining Productivity: The Advantage of Optical Ore Sorting

Nov 23, 2023

Ore Sorting vs Traditional Hand-Picking | Mining's Evolution

Nov 11, 2023

Ore Sorting vs Traditional Hand-Picking | Mining's Evolution

Nov 11, 2023

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

Silicon Metal Sorting Machine automatic sorting machine

Sep 09, 2022

Silicon Metal Sorting Machine automatic sorting machine

Sep 09, 2022

AI intelligent ore sorting machine, industrial and mining separation new leap

Oct 15, 2022

AI intelligent ore sorting machine, industrial and mining separation new leap

Oct 15, 2022

A technology recovery recycling industrial silicon in silicon slag

Oct 15, 2022

A technology recovery recycling industrial silicon in silicon slag

Oct 15, 2022

Lead zinc ore sorting technology - improve efficiency and reduce cost!

Oct 22, 2022

Lead zinc ore sorting technology - improve efficiency and reduce cost!

Oct 22, 2022