What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

An ore sorter is a specialized machine used in the mining industry to separate valuable ore from impurities. Utilizing techniques such as sensors, cameras, and automated sorting algorithms, it efficiently identifies and separates different types of ore based on their physical and chemical properties. This technology significantly improves the efficiency of the mining process by reducing the amount of impurities that need processing and increasing the concentration of valuable ore. Ore sorters can ensure increased productivity and cost-effectiveness in the mining industry.

Types of Ore Sorters

1. Color Ore Sorter

Utilizes color recognition technology to distinguish between different minerals based on their color properties. This sorter is effective in quickly identifying and separating ore particles.

2. AI Intelligent Sorting Machine

Harnesses the power of artificial intelligence to analyze and categorize ore based on predefined parameters. This cutting-edge technology enhances the sorting accuracy and efficiency.

3. X-ray Intelligent Sorter

Employs X-ray technology to penetrate and analyze ore particles. This sorter is particularly useful in identifying and separating minerals with distinct X-ray absorption characteristics.

4. Mineral Sand Sorter

Specialized for sorting mineral sands, this machine efficiently separates valuable minerals from the surrounding waste based on their unique physical properties.

5. Ultraviolet-ray Sorter

Utilizes ultraviolet rays to detect and classify ore particles. This sorter is effective in identifying minerals that exhibit specific UV light interactions.

6. Infrared Sorter

Operates by analyzing the infrared spectrum of ore particles, allowing for the separation of valuable minerals from waste based on their unique infrared signatures.

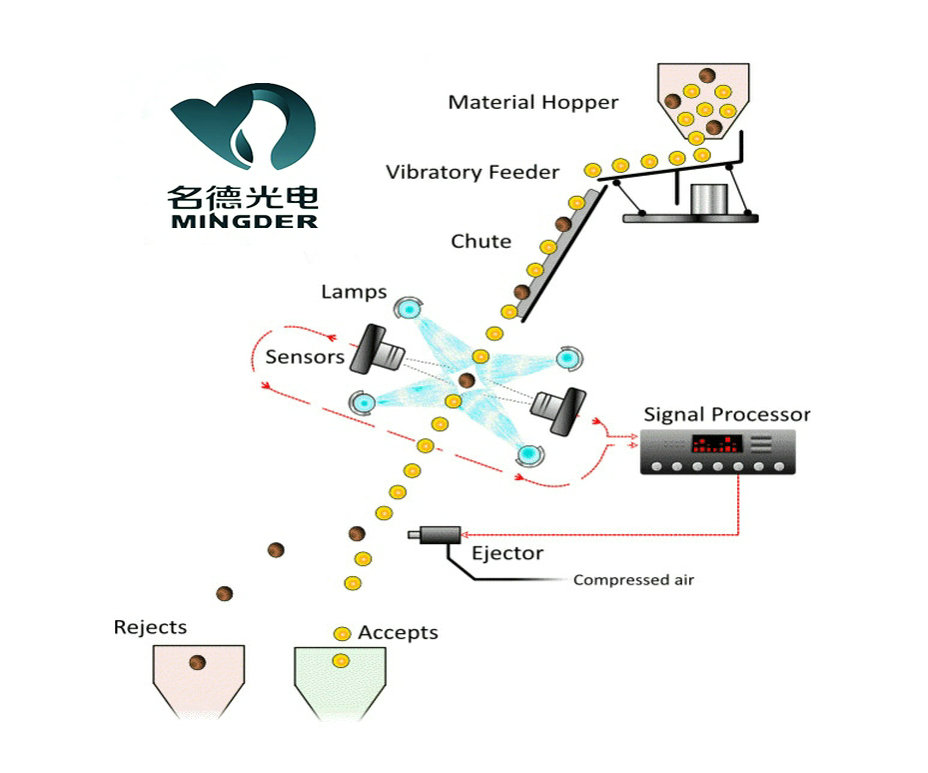

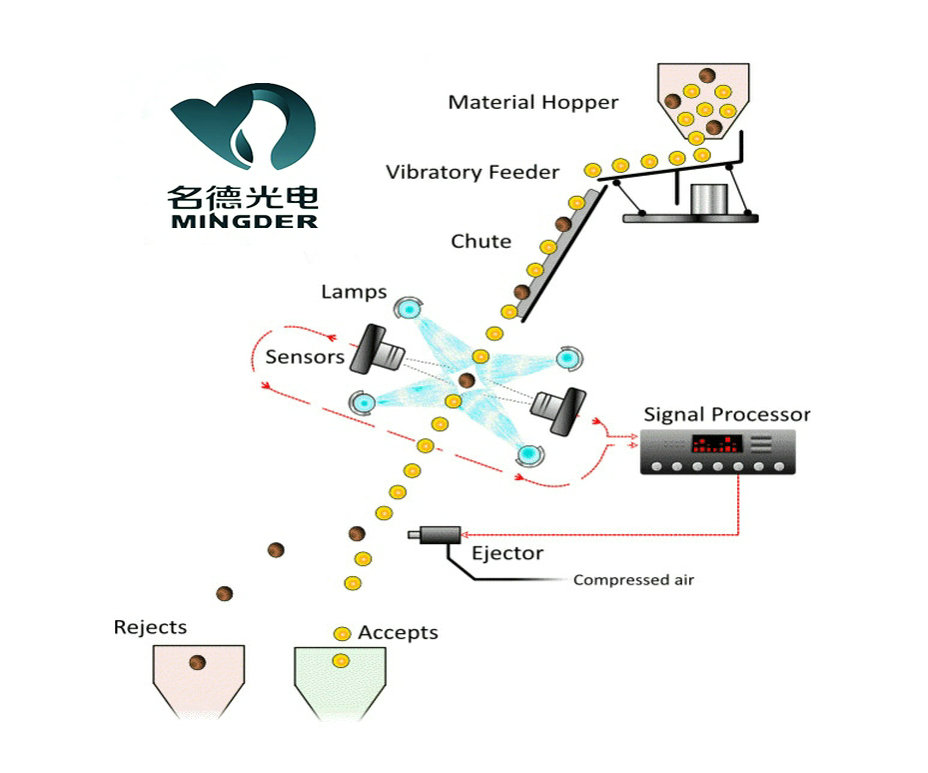

Working Principle of Optical Ore Sorter

Material Illumination

Ore particles are illuminated using various light sources such as visible light, X-ray, ultraviolet-ray, or infrared light.

Optical Sensors

Specialized sensors capture the reflected or transmitted light from the illuminated particles.

Spectral Analysis

The optical system analyzes the spectrum of light interacting with each particle, identifying distinctive spectral patterns associated with different minerals.

Algorithmic Processing

Advanced algorithms process the gathered optical data, making rapid decisions about the nature of each particle, distinguishing between valuable and waste materials.

Sorting Mechanism

Based on the analysis, a sorting mechanism is activated to separate valuable ore from waste material, ensuring efficient processing.

Real-time Operation

The entire process occurs in real time, allowing for quick and precise separation of valuable minerals from non-valuable ones.

Advantages of Ore Sorting Technology

1. Increased Efficiency

By separating valuable rocks from waste before entering the mill, ore sorters improve overall milling efficiency, reducing the need for energy-intensive grinding.

2. Environmental Benefits

Reduced waste generation, including tailings, minimizes the environmental impact of mining operations. Lower water consumption contributes to sustainable mining practices.

3. Improved Product Quality

Ore sorting removes low-grade or contaminated rocks, resulting in higher average ore quality and increased yields of valuable metals in the final product.

4. Cost Savings

Reduced milling costs are achieved by processing a higher average ore grade and less waste material, leading to significant savings for mining companies.

5. Increased Resource Utilization

Ore sorting allows for the extraction of valuable metals from previously uneconomic ore deposits, enhancing resource utilization and overall production.

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023