Subscribe to our newsletter and always be the first to hear about what is happening.

Comprehensive Utilization of Coal and Coal Gangue

Aug 03, 2024Coal and gangue are two different substances produced during coal mining and processing. Coal is a fossil fuel that is mainly composed of elements such as carbon, hydrogen, oxygen, nitrogen, sulfur and phosphorus, and has a high energy density and calorific value of combustion. Coal is usually black in color, has a relatively compact texture and contains fewer impurities. In contrast, gangue is a solid waste produced during coal mining and selection, which contains a lower carbon content and a higher ash content. It is usually gray or dark gray and contains more impurities. The density of gangue is lower than that of coal, so it weighs more in the same volume. In addition, the hardness of gangue is also higher than that of coal, and it is not easy to be broken manually.

Gangue, on the other hand, was often regarded as waste disposal in the past due to its lower energy value and higher environmental pollution potential. However, with the improvement of comprehensive resource utilization and environmental protection awareness, the comprehensive utilization technology of gangue has been developed, and its application in the production of building materials, filling of goafs, land reclamation, and production of chemical products has gradually increased.

Taking the field of building materials as an example, coal gangue has the following main applications:

Cement production: coal gangue can be used as a raw material for the production of ordinary silicate cement, special cement and clinker-free cement, and can partially or completely replace clay to prepare cement raw materials.

Production of sintered bricks: coal gangue sintered bricks are of good quality and uniform color, and are a commonly used building material.

Production of lightweight aggregate: Lightweight aggregate is a porous aggregate used to reduce the relative density of concrete. Coal gangue can be used to produce such materials.

Production of coal gangue asbestos: Coal gangue asbestos made from coal gangue and lime as raw materials and melted at high temperature is a building material.

Production of blocks: coal gangue can also be used to produce building materials such as blocks.

Production of other building materials: According to the mineral composition of coal gangue, it can be used as a siliceous raw material or an aluminum raw material, and is used in the production of many sintered ceramic (porcelain) building materials.

Production of chemical products: Gangue can be used to produce chemical products such as crystalline aluminum chloride, water glass, and ammonium sulfate.

Backfill and reclamation: Gangue can be used to fill coal mining subsidence areas and open-pit mines for land reclamation.

In addition, gangue has the following convenient applications:

Conversion of gangue into organic fertilizer: Through specific biotechnology treatment, gangue can be converted into biological organic fertilizer to improve the productivity of soil ecosystems. This technology not only realizes the resource utilization of gangue, but also helps to improve soil quality and promote sustainable agricultural development.

High-value utilization of gangue: After grinding, pulping, grading and other process treatments, gangue can be used to produce high-value-added products such as catalysts, pigments, and fillers. These products are widely used in many fields such as plastics, rubber, and coatings, realizing the resource utilization and recycling of gangue.

Gangue overburden isolation grouting filling technology: This is a technology that injects gangue as filling material into the overburden separation zone through ground drilling, which effectively prevents and slows down ground subsidence. This technology fundamentally solves the problem of gangue treatment in coal mines, saves treatment costs, and provides a new solution for gangue disposal.

In order to improve the comprehensive profit efficiency of coal and gangue, the separation of coal and gangue is particularly important as an important step in the coal processing process.

The following are some current methods for separating coal and gangue:

1. Vibrating screen gangue separation system: By establishing a vibrating screen gangue separation system on the underground centralized belt, effective separation of coal and gangue is achieved. This system can realize the direct loading and lifting of gangue, reduce the main shaft lifting and gangue washing in the coal washing plant, reduce the ash content of washed coal, and improve the recovery rate of raw coal.

The working principle of this system is based on vibration mechanics and screening principles. In this process, the vibrating screen is driven by a motor to make the screen body vibrate at high frequency, and the material jumps on the screen surface. Due to the different physical properties of coal and gangue, their motion states on the vibrating screen surface are also different, resulting in the effective separation of the two.

Specifically, when the screen surface of the vibrating screen vibrates, large particles of material will be thrown above the screen surface due to inertia, while small particles of material will fall below through the screen. In this way, materials of different particle sizes are separated. The design of the vibrating screen usually takes into account the differences in the characteristics of coal and gangue, including their density, humidity and shape, to ensure efficient sorting.

The vibrating screen gangue sorting system is mainly composed of screen box, screen, vibrator, vibration damping spring and other components. There are multiple layers of screen inside the screen box, and each layer of screen corresponds to different particle size requirements. The vibrator generates vibration force, causing the screen box and screen to vibrate at high frequency, thereby achieving material separation. The vibration damping spring is used to absorb the vibration generated by the vibrating screen during operation and reduce the transmission of vibration to the ground or other equipment.

The operation process usually includes three steps: feeding, screening and discharging. First, the raw coal and gangue mixture is fed into the feeding port of the vibrating screen. Then, the vibrating screen starts working and the material is screened on the vibrating screen surface. Finally, the screened coal and gangue are discharged from both sides of the screen respectively to complete the sorting process.

In practical applications, the vibrating screen gangue sorting system may be optimized and improved according to the specific conditions of different coal mines to improve sorting efficiency and reduce energy consumption. For example, the vibration frequency and amplitude of the vibrating screen can be adjusted to adapt to different material characteristics, or the screening accuracy can be improved by improving the design of the screen. In addition, the introduction of intelligent control systems can further improve the automation and stability of the system.

2. Gangue sorting system based on X-ray and machine vision: Use X-ray and machine vision technology to identify coal and gangue, calculate the thickness value of coal and gangue through image processing algorithm, and fuse the thickness of coal and gangue identified by visual images with X-ray attenuation images to obtain recognition decision information.

The application of X-ray and machine vision technology in coal gangue sorting mainly involves the following steps:

Use of imaging system: Use X-ray imaging system to scan coal and coal gangue to obtain the internal structure and composition information of the material. This information is usually manifested as different materials absorb X-rays to different degrees, thus forming contrast in imaging.

Image recognition and analysis: Through machine vision technology, the images obtained by the X-ray imaging system are processed and analyzed. Deep learning algorithms are used to train models to automatically identify the characteristics of coal and coal gangue, such as color, density, shape, texture, etc.

Automated sorting: After identifying coal and coal gangue, the control system will guide the actuator, such as high-pressure wind or robotic arm, to separate the gangue from the coal. This process can achieve high-efficiency and high-precision sorting, reduce labor costs, and improve sorting quality.

Intelligent system: Modern gangue sorting systems not only rely on hardware equipment, but also integrate data analysis and artificial intelligence algorithms, so that the system has self-learning capabilities, can adjust the sorting strategy according to different coal quality characteristics and environmental conditions, and realize unattended operation.

The combination of these technologies represents the advanced level in the field of coal sorting, which helps to improve resource recovery and reduce environmental pollution.

3. Photoelectric sorting system: Gangue photoelectric sorting technology is a modern method of sorting coal and gangue using photoelectric sensors and image processing technology. This technology can achieve rapid and accurate identification of coal and gangue, thereby improving the quality of coal and the comprehensive utilization rate of resources. Photoelectric sorting systems usually include components such as light sources, detectors, image processing units and control systems. By scanning the materials on the conveyor belt, the system can detect the differences in spectral characteristics of different substances and classify them accordingly.

The latest research and applications show that gangue photoelectric sorting technology is developing towards intelligence and high efficiency. For example, a study proposed an intelligent gangue sorting system based on deep reinforcement learning, which can achieve more than 95% gangue identification accuracy and more than 90% sorting efficiency. In addition, there are studies on the key common technologies of multi-arm gangue intelligent sorting robots, which have achieved the stable grasping of dynamic gangue transmitted at high speed by the manipulator, improving the sorting efficiency and the collaborative working ability of the system.

The advantage of the optoelectronic sorting technology of gangue is that it can realize non-contact sorting, reduce damage to materials, and reduce dust and noise pollution. In addition, the intelligent sorting system can self-learn and optimize the sorting strategy to improve the accuracy and efficiency of sorting. The application of these technologies helps to achieve efficient utilization of coal resources and environmental protection, which is in line with the development trend of green mine construction.

In addition, the application of optoelectronic sorting technology can also reduce equipment failure rate, reduce management costs, optimize process flow, and improve clean coal recovery rate, which are directly reflected in the improvement of production efficiency. The combination of intelligent lighting and personnel positioning management platform further enhances the intelligence level of coal preparation plants and improves the standards of safe production.

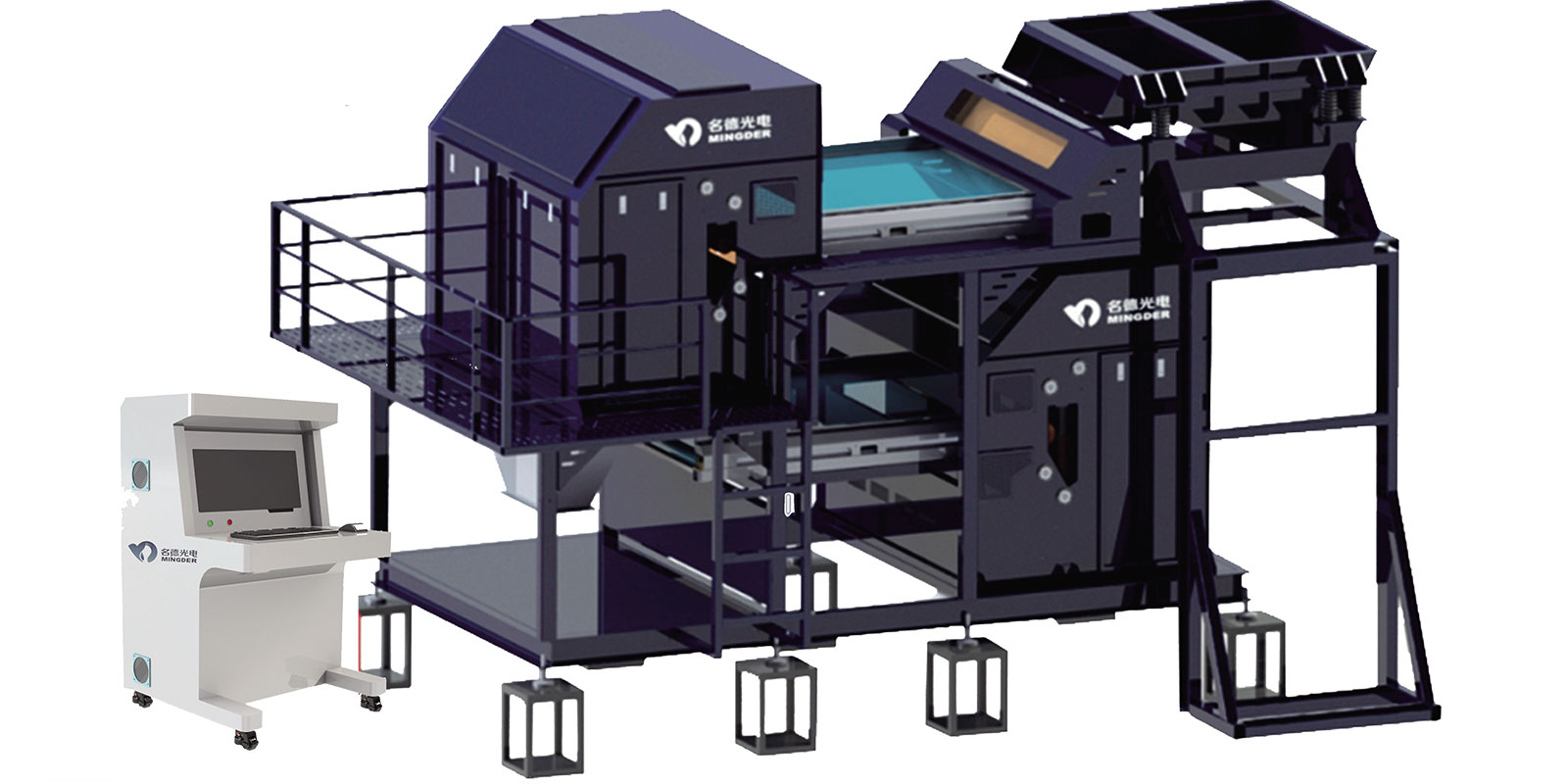

The AI intelligent sorting machine launched by Anhui Mingde Optoelectronics Technology Co., Ltd. uses deep learning and machine vision technology to automatically identify and sort coal gangue. This technology can significantly improve sorting efficiency, reduce labor costs, and reduce environmental pollution.