How phosphate ore is enriched by beneficiation

Nov 03, 2022

How phosphate ore is enriched by beneficiation

Nov 03, 2022

Phosphate ore is a general term for phosphate minerals that can be used as an important chemical material, mainly used in medicine, food, matches, dyes, sugar, ceramics, national defense and other industrial sectors, as well as an important mineral raw material for the extraction of phosphate fertilizer.

China's phosphate ore reserves are currently ranked third after Morocco and the United States, domestic phosphate ore distribution is concentrated in Yunnan, Guizhou, Sichuan, Hubei and Hunan 5 provinces, the total reserves account for about 74.5% of the country, phosphate ore by the formation of two main types of apatite and phosphorite, where apatite is mainly in igneous or metamorphic rocks in the form of crystalline apatite, phosphorite is gray-black, cryptocrystalline microcrystalline structure, breccia structure. Now known to contain phosphorus minerals in more than 120 kinds, now the industrial use of phosphate ore is mainly apatite, in fact, for sulfur phosphorus aluminum strontium stone, blue iron stone, etc., of which more than 95% of the phosphorus element mainly several species in the apatite.

There are more associated minerals in natural phosphate ore, mainly miscellaneous rocks and veins, specifically two types of silica minerals and carbonates. Silica minerals are mainly quartz, quartz square, flint, opal, clay ore or other silicate minerals such as feldspar, mica, etc. Carbonates are mainly limestone and dolomite.

The goal of phosphate ore enrichment is to maximize the separation and removal of impurity minerals and improve the grade and quality of phosphate ore. The enrichment process includes crushing and separation (crushing and crushing), washing and classification (washing and classification), separation and purification (flotation, magnetic separation, photoelectric separation, calcination, heavy media separation), the three main steps.

The process and operation of phosphate ore preconcentration and discarding are as follows.

1. Crushing and separation

Phosphate ore enrichment requires crushing and smashing to achieve monomeric dissociation of phosphate minerals and veinlets, mainly because the phosphate minerals and miscellaneous stones are in cementation together, the original ore can only be broken and ground to achieve monomeric dissociation. This step is the basic step of phosphate ore enrichment.

2. Water washing classification

Phosphate ore due to the mining process in the wet ore adhering to the mud, only after water washing to remove the mud, while water washing can also remove soluble water substances and so on. Because the phosphate ore after crushing, water washing particle size is different, you need to go through the classification equipment to sort out the appropriate particle size. Only then can further enrichment and purification.

3. Separation and purification

After the above process, phosphate ore into the final separation and purification steps, phosphate ore purification are mainly heavy media separation, photoelectric separation, calcination, flotation, magnetic separation.

1) Flotation

Flotation mainly has positive and negative flotation, mainly using phosphate ore and miscellaneous ore physical properties are different, the use of flotation agents to make phosphate ore float or sink, so as to achieve the purpose of separation.

2) Magnetic separation

The use of iron-containing magnetic minerals in phosphate ore, under the action of magnetic separator, and non-magnetic vein recovery of phosphate ore containing iron magnetic minerals separation.

3)Calcination

Mainly used to remove organic matter, carbon dioxide and part of the fluorine in the phosphate ore, calcination temperature of 400 ~ 1400 ℃, depending on the purpose.

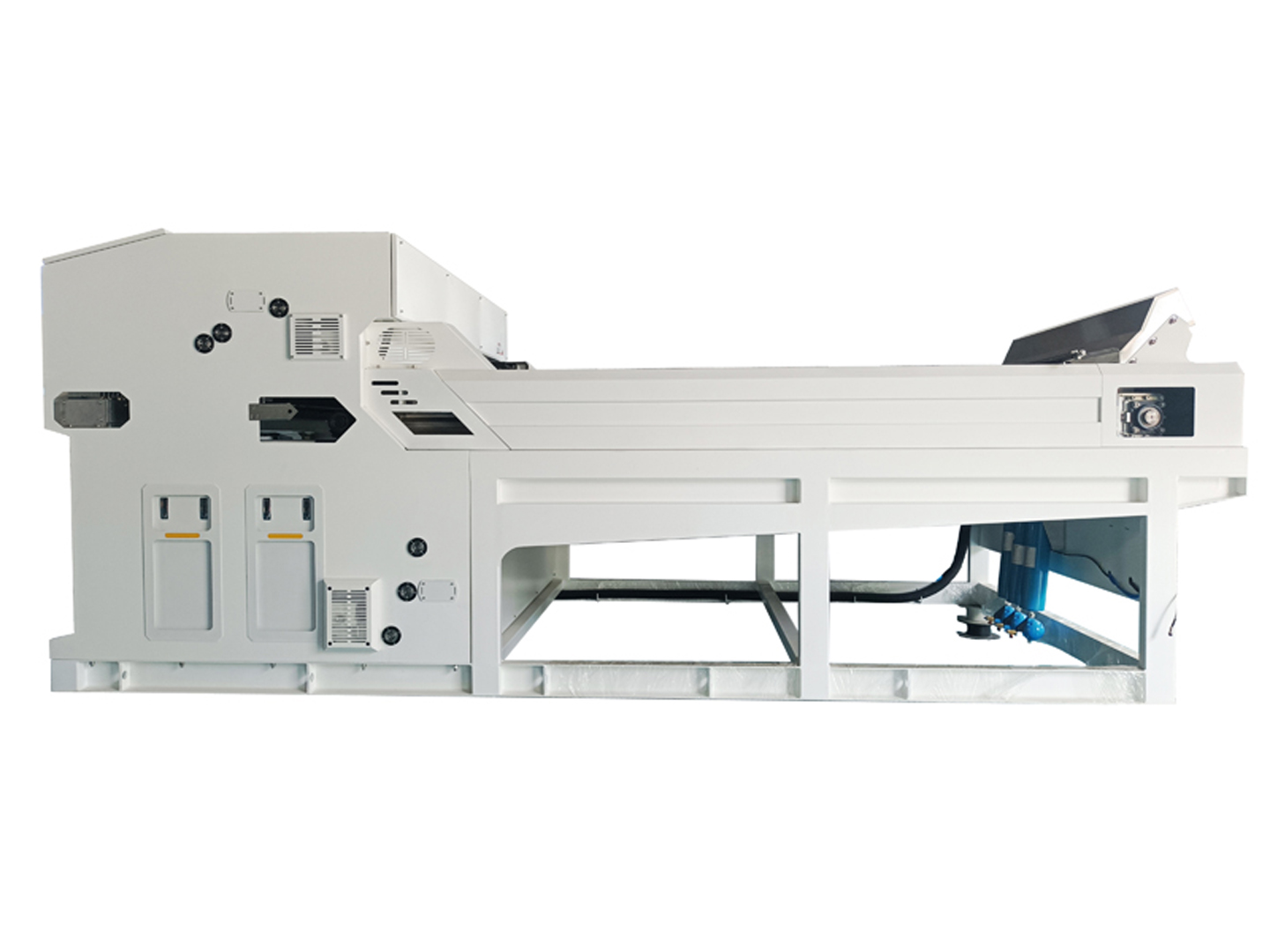

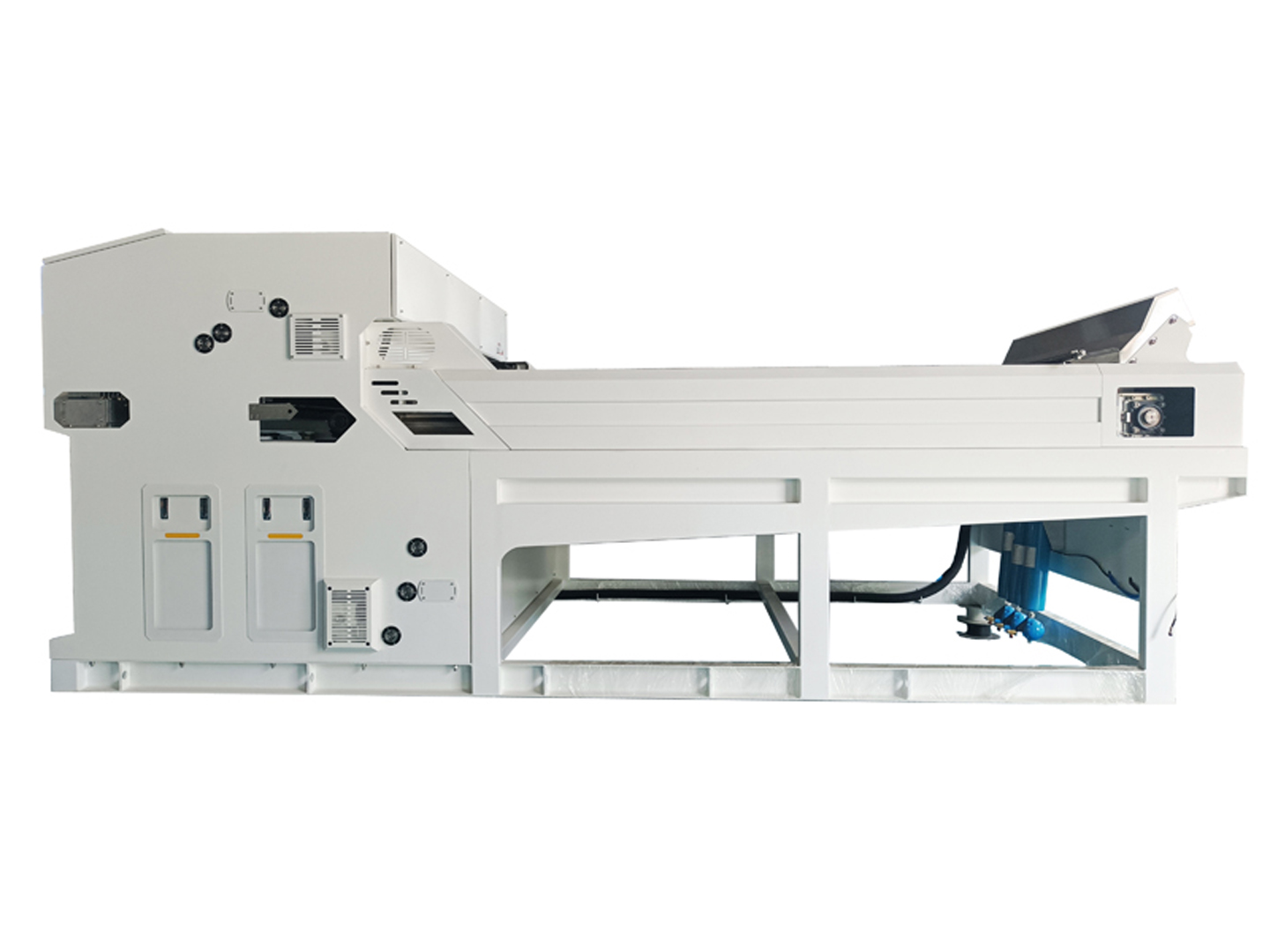

4)Photoelectric sorting

Mainly phosphate ore after crushing, the use of ore surface characteristics differences, through the color sorter or artificial intelligence sorter for sorting.

5)Heavy media sorting

Using the difference in density between phosphate ore and other minerals, a medium is selected so that one medium floats and the other sinks, thus achieving enrichment.

The above is the way of phosphate ore sorting and purification applications, where the mainstream sorting is mainly using heavy media sorting and photoelectric sorting (X-ray sorting), a small number of flotation, magnetic, calcination process.

Next, we will elaborate on the mainstream phosphate ore separation and purification process. First of all, heavy media sorting is the use of phosphate ore, dolomite, shale specific gravity differences to sort, where phosphate ore, dolomite, shale density distribution of 2.2g/cm³, 2.8-2.9g/cm³, 2.55 ~ 2.65g/cm³, in the actual sorting process, subject to the influence of a number of factors, phosphate enrichment has nearly 8% or so dolomite carry out, greatly affecting the phosphate enrichment after the quality.

At the same time, there are some phosphate mining enterprises have used X-ray equipment for sorting, X-ray equipment sorting is similar to heavy media sorting, mainly using the density difference between mineralized and non-mineralized materials for sorting, in the field production process, because the phosphate ore and associated ore density difference value is small, imaging is closer, there will be throwing waste tailings phosphate ore with high, the actual application of phosphate ore is not particularly ideal.

The current stage of the situation and problems faced by phosphate ore sorting, the introduction of artificial intelligence sorting machine, the main principle is the use of phosphate ore surface characteristics of the differences in sorting, to accurately identify the phosphate ore and dolomite and shale surface texture, luster, color, shape and other characteristics of the subtle differences, a composite sorting, sorting effect is higher than the current stage of phosphate ore enrichment accuracy and effectiveness.

Mingde photoelectric recently used artificial intelligence ore sorting machine,digital color separating machine, sorting phosphate ore original grade of about 20, after enrichment of the concentrate grade of about 30, tailings in the phosphate ore grade is less than 5. fully able to meet the target sorting requirements. At the same time, it can guarantee the amount of bad material to be taken out under the premise of enriching the phosphate ore grade, and also take into account the rate of good material to be taken out from the waste tailings.

Here is the phosphate ore after sorting

Mingde photoelectric focus on the field of ore sorting, after a long period of technical accumulation and ore field of sorting applications, the introduction of four series of more than 20 products, widely used in fluorite, talc, wollastonite, high crystal silicon, iron ore, gold ore, lead and zinc ore, coal and coal gangue, vanadium ore and nearly 100 kinds of metal, non-metallic ore field of sorting applications.

Edit by Jacky

How phosphate ore is enriched by beneficiation

Nov 03, 2022

How phosphate ore is enriched by beneficiation

Nov 03, 2022