Subscribe to our newsletter and always be the first to hear about what is happening.

How to Avoid Ore Waste in Ore Processing

Aug 10, 2024Yesterday, one of my foreign customers told me that he is facing a serious dilemma, that is, the problem of ore waste in ore processing. This customer has his own mine and ore processing plant, and the overall output is 5,000 tons of finished products every month. The monthly output is not large, but the ore waste caused is not small.

Today, let's discuss the ore waste problems faced in ore processing and the causes of these problems, and analyze these causes to further find ways to avoid these problems.

First of all, we will discuss the links and causes of ore waste in ore processing.

Generally speaking, in the ore processing process, waste mainly occurs in the following stages:

1. Mining stage: Improper mining methods or unreasonable mining sequence may cause useful minerals to be excavated together with waste rocks, resulting in ore loss. (Because this article mainly discusses the problem of ore waste in ore processing, the mining stage will not be discussed in detail.)

2. Transportation and handling stage: Ore may be scattered during transportation, especially in long-distance transportation or bad weather conditions, which will lead to the loss of usable ore.

3. Ore crushing and screening: If crushing and screening are not done properly, the ore may be over-crushed or the particle size distribution may be unreasonable, thus affecting the efficiency of subsequent processes and the mineral recovery rate.

4. Grinding and classification: Grinding is an important step to improve the degree of mineral dissociation, but if it is not properly controlled, it may cause energy waste and mineral loss. In addition, inappropriate classification may cause useful minerals to mix with gangue, reducing the recovery rate.

5. Mineral sorting stage: During the mineral processing process, due to improper equipment performance, operation or unreasonable process parameter settings, the separation of useful minerals from gangue may not be thorough, resulting in a decrease in recovery rate. Including gravity separation, flotation, magnetic separation, etc., the efficiency of these processes directly affects the final mineral recovery rate. Improper selection of mineral processing methods or inappropriate operating conditions may cause a large amount of valuable minerals to be left in the tailings.

6. Concentration and dehydration: In the final stage of mineral processing, concentration and dehydration are to reduce the amount of tailings and obtain concentrates suitable for transportation and further processing. If these steps are inefficient, energy consumption and processing costs will increase.

7. Tailings treatment stage: Poor tailings management, such as improper tailings pond design or improper tailings treatment, may result in the failure to effectively recover useful minerals and waste resources.

The reasons for these wastes include:

1. Technical level: backward mining and mineral processing technology may lead to inefficiency and waste of resources.

2. Poor management: Lack of effective resource management and supervision may lead to unnecessary losses.

3. Equipment failure: Aging or improper maintenance of equipment may lead to reduced production efficiency and ore loss.

4. Environmental factors: Complex geological conditions or extreme weather conditions may affect the processing and transportation of ore, increasing the risk of loss.

In order to reduce these wastes, it is necessary to adopt modern mining and mineral processing technology, optimize process flow, strengthen equipment maintenance and management, and implement strict environmental protection measures.

How to operate specifically, we still need to come from practice, go to practice, and optimize our ore processing process according to each stage.

1. In view of the waste caused by the transportation stage, mining companies can optimize the transportation route planning, try to find the transportation route, reduce the transportation time and cost, and consider environmental factors, try to avoid transporting ore in bad weather and bumpy roads, and improve the stability of transportation; use suitable transportation tools, such as electric wheel loaders and large mining trucks, and implement systematic management of the fleet and tracking monitoring.

2. In view of the waste caused by the ore crushing and screening stage, mining companies can use primary crushing, secondary crushing and tertiary crushing to classify the ore, and choose different crushing equipment according to the properties of different ores, for example: jaw crusher is suitable for coarse crushing, cone crusher is suitable for medium and fine crushing, impact crusher is suitable for medium and fine crushing of soft and medium hard materials, and high-efficiency crushing technology can also be introduced, such as new hydraulic cone crusher, which can more accurately control the work of the crusher and improve the crushing effect.

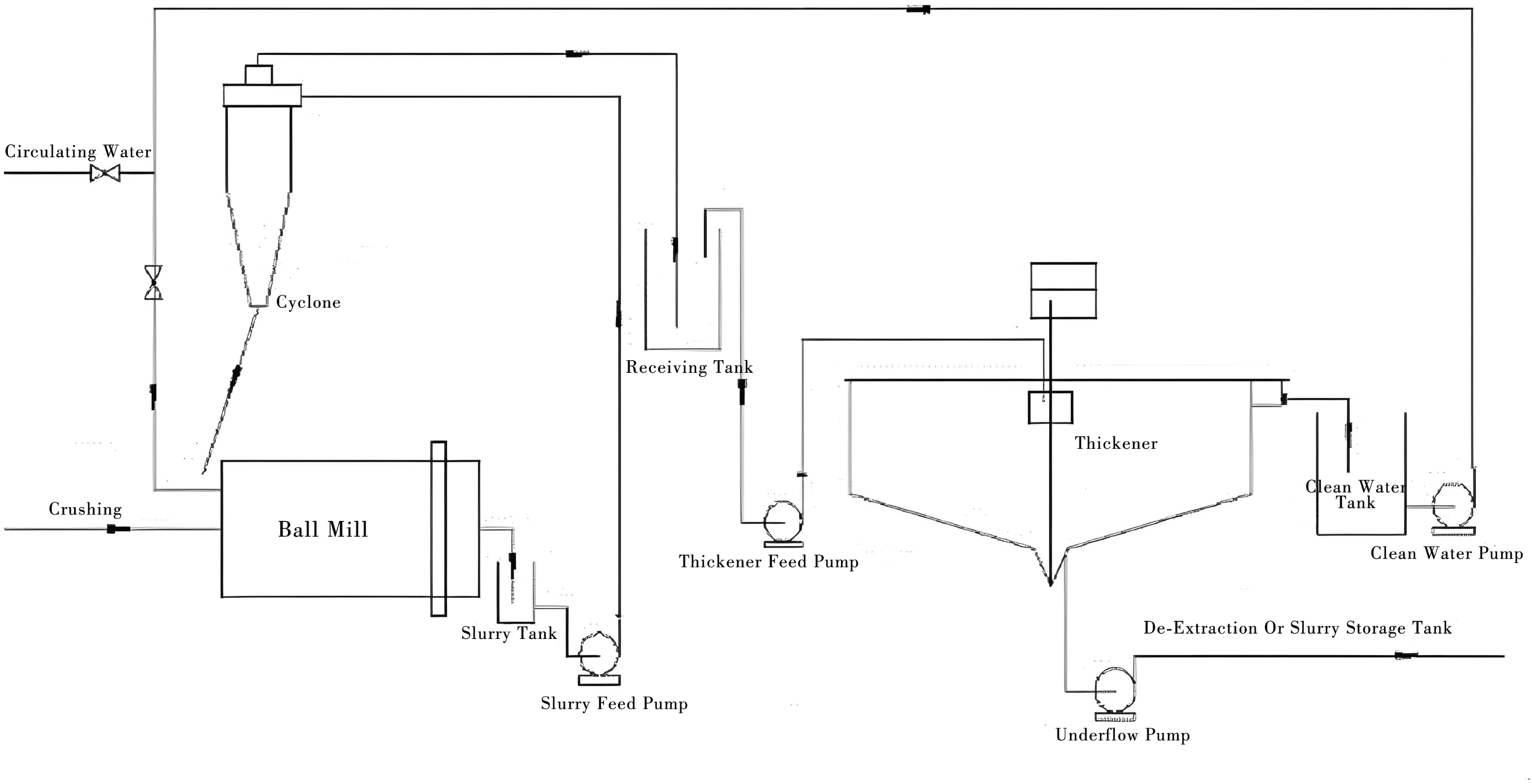

3. In view of the ore waste caused by the grinding and classification stage, mining companies can use closed grinding system and suitable grinding machine. A closed grinding system is a grinding process in which the grinding equipment and its matching classification equipment form a closed-loop circulation system. In this system, the material after grinding is first classified by the classification equipment, and the unqualified coarse-grained material is returned to the grinding equipment for re-grinding, while the qualified fine-grained material flows to the next process. In this way, the closed grinding system can effectively control the product particle size, reduce over-grinding, and improve grinding efficiency and product quality.

The process of closed-circuit grinding usually includes the following steps:

1) Feeding: The raw materials are fed into the mill for preliminary crushing and grinding.

2) Classification: The material after grinding enters the classification equipment, such as a spiral classifier or a hydrocyclone, for classification.

3) Return sand: The coarse-grained material (return sand) separated by the classification equipment is returned to the mill for re-grinding.

4) Circulation grinding: The return sand enters the mill together with the fresh feed ore to form a circulation grinding process.

5) Finished product discharge: After multiple cycles of grinding, the material that reaches the required particle size is discharged by the classification equipment as a finished product.

In the closed-circuit grinding process, the control of grinding efficiency and product particle size depends on the working efficiency of the classification equipment and the adjustment of the return sand ratio. The return sand ratio refers to the ratio of the return sand amount to the new feed amount. The optimization of this ratio is crucial to achieve efficient grinding.

Depending on the properties of the ore, the following closed-circuit grinding equipment can be selected:

1) Ball mill: suitable for fine grinding of most hard ores, and can form a closed-circuit system with spiral classifiers or high-efficiency screening equipment.

2) Rod mill: suitable for coarse grinding or pre-grinding, especially when processing brittle materials, it can be used in conjunction with grid-type or overflow classifiers.

3) Autogenous mill: suitable for processing certain specific ores, with low energy consumption, but with certain requirements for the hardness and grindability of the ore.

When selecting closed-circuit grinding equipment, it is also necessary to consider the number of grinding stages, whether it is closed-circuit grinding, and the conditions of different classification operations. These factors jointly determine the design of the grinding process to ensure the best grinding effect and economic benefits.

In the closed-circuit grinding process, the commonly used classification equipment mainly includes the following types:

1) Spiral classifier: According to the immersion state of the spiral shaft, the spiral classifier can be divided into high weir type and submerged type. The high weir spiral classifier is suitable for coarse particle classification, while the submerged spiral classifier is suitable for fine particle classification. The spiral classifier classifies the material after grinding and discharges the coarse particle material through the rotation of the spiral blade.

2) Hydrocyclone:It uses the centrifugal force of the water flow for classification and is suitable for materials of various particle sizes. There is a conical cylinder inside the hydrocyclone. The material and water enter the cylinder together. Due to the action of centrifugal force, materials of different particle sizes are separated.

3) Cone classifier: Classification is carried out through the free fall motion of the material in the conical cylinder and the action of centrifugal force. The cone classifier is suitable for the classification of medium-sized materials and can effectively separate fine and coarse particles.

4) Trough classifier: It consists of an inclined trough body. The material settles under the action of gravity and the inclination angle of the trough body to achieve classification. The trough classifier has a simple structure and is suitable for the preliminary classification of larger block materials.

These classification equipments have their own characteristics and are suitable for different grinding conditions and material characteristics. In actual production, the appropriate classification equipment is selected according to the requirements of the grinding process and the physical properties of the ore to achieve the best grinding effect.

The vertical mill is a high-efficiency grinding equipment, which is mainly used for grinding materials of various hardness, such as cement raw materials, coal, slag, etc. Its working principle is to achieve material crushing and grinding through the rolling friction between the grinding roller and the grinding disc. The main components of the vertical mill include grinding rollers, grinding discs, bearings, reducers, motors, separators and fans. The materials are crushed by the grinding rollers in the grinding disc and are separated and transported under the action of wind.

The vertical mill integrates crushing, drying, grinding and classification, simplifies the process flow, reduces the number of equipment, reduces investment and operation and maintenance costs, and the overall sealing design and full negative pressure operation reduce dust spillage, reduce environmental pollution and also reduce ore loss.

4. For the waste caused in the mineral sorting stage, mining companies should choose appropriate mineral sorting methods according to the characteristics of the ore, optimize the mineral sorting technology, improve the automation and intelligence level of mineral sorting, and effectively reduce the errors of manual operation.

Mingde Optoelectronics Technology Co., Ltd. has been devoted to the research and production of intelligent sorting equipment for mining for ten years, and has successively launched Mingde ore color sorters and Mingde AI intelligent ore sorters, introducing artificial intelligence technology and big digital technology in the field of mineral processing, and further improving the efficiency and accuracy of mineral processing. The heavy-duty ore sorter launched by Mingde in 2022 can sort ores with a particle size of 8-15cm, bringing the hourly output of the ore sorter to 200 tons, meeting the requirements of large-scale pre-sorting of large mining companies, and reducing the pressure of subsequent flotation in large quantities, which is more energy-saving and environmentally friendly.

CCD Sensor Based Ore Color Sorter

Mingde ore sorter can establish a sorting mode according to the user's sorting needs, and realize accurate sorting of ores of different particle sizes and types; customers can also adjust the machine parameters and the sorting accuracy according to their actual situation to meet the diversified and personalized sorting requirements of users.

The whole machine is highly intelligent, and can continuously improve the sorting effect through the machine's learning mode. It can realize remote debugging, intelligent monitoring, remote service, and remote software upgrades to help customers enjoy the latest photoelectric mineral processing technology.

Heavy Duty AI Mineral Sorting Machine

The vibrating feeding part and the main body of the equipment adopt a split structure to avoid the impact of the vibration of the hopper on the main machine during the feeding process, making the equipment run more stably. In contrast, the main body of the sorting adopts a closed whole machine structure, which enables the machine to better adapt to the requirements of harsh environments such as high dust, high pollution, and high corrosion in the industrial and mining industries.

5. For the waste generated during the concentration and dehydration process, mining companies can adopt the following methods to improve the recovery rate of ore.

1) Optimize equipment design: Select efficient concentration equipment and dehydration equipment, such as high-efficiency deep cone concentrators and vibrating inclined plate high-efficiency concentrators. These equipment can handle more materials and improve material handling capacity and efficiency.

2) Adjust operating parameters: Reasonably adjust the operating parameters of the concentrator and dehydration equipment, such as feed rate, flocculant addition, etc., which can significantly improve the equipment's processing capacity and reduce energy consumption.

3) Implement intelligent control strategy: Use modern automation technology to establish an intelligent control system for the concentrator, monitor and adjust the working parameters in real time, so that the equipment always maintains the best operating state and reduces the loss caused by improper operation.

4) Application of new materials and new equipment: The use of high-wear-resistant materials to manufacture key components of the equipment can significantly extend the service life of the equipment, reduce the maintenance frequency, and improve the overall processing capacity and efficiency.

5) Improve the technical level of operators: Improving the technical level and operating ability of operators through regular training and education is an important measure to improve the processing capacity of equipment.

6) Real-time monitoring and intelligent control system: The introduction of real-time monitoring and intelligent control system can realize real-time monitoring and automatic adjustment of the operating status of the equipment, and improve the sorting efficiency and safety.

6. For the waste caused by the tailings treatment stage, mining companies can further recycle the tailings that have been discharged after preliminary beneficiation treatment to extract the remaining valuable metals or non-metallic minerals. For the tailings generated during the beneficiation process, mining companies can also treat and reuse them in a variety of ways to reduce environmental pollution, save resources and energy, and transform them into a collection of technologies for valuable products. These technologies include but are not limited to the physical and chemical treatment of tailings, and the use of tailings as raw materials in building materials, filling materials and other fields. The purpose of tailings comprehensive utilization technology is to maximize the utilization of tailings resources, reduce the construction and maintenance costs of tailings ponds, and reduce the negative impact on the environment.

Common types of tailings comprehensive utilization technologies include:

1) Tailings backfill: Use tailings as filling materials in mine goafs to reduce surface collapse and environmental damage.

2) Tailings sand making: Use tailings as construction sand after treatment.

3) Production of building materials: Use tailings to produce cement, bricks, aerated concrete and other building materials.

4) Soil conditioner: Tailings can be used to improve soil structure and increase soil fertility.

5) Environmental remediation materials: Tailings are used for the solidification and stabilization of heavy metal contaminated soil.

In short, avoiding ore waste caused by ore processing and improving ore recovery rate are of great economic and environmental significance to the mining industry. Economically, by improving ore recovery rate, the effective utilization of mineral resources can be increased, resource waste can be reduced, and the economic benefits of enterprises can be improved. This is particularly important in the context of increasingly scarce resources, as it helps extend the service life of mines and maintain the stability of the supply chain. Environmentally, improving ore recovery rates helps reduce the amount of tailings produced and reduce the burden on the environment. The reduction of tailings ponds can reduce the risk of geological disasters, reduce pollution to water resources and soil, protect the ecological environment, and achieve sustainable development of the mining industry.

In addition, improving ore recovery rates is also in line with national policies and regulations, responding to the call for comprehensive resource utilization and environmental protection. The government encourages the use of advanced technologies and management measures to improve resource utilization efficiency and reduce environmental pollution, which has a positive impact on the long-term development of enterprises and the fulfillment of social responsibilities.

There is still a lot to discuss about how to avoid ore waste in ore processing. Today we have discussed each link one by one. If you still have questions you want to ask or have your own unique understanding, we welcome you to actively share.