Subscribe to our newsletter and always be the first to hear about what is happening.

How to select suitable beneficiation process and reduce beneficiation cost according to ore characteristics?

Jul 07, 2023How to select suitable beneficiation process and reduce beneficiation cost according to ore characteristics?

As the core of ore utilization in the ore industry, beneficiation plays a vital role in improving the ore grade and recovery rate. However, with the reduction of high-grade, easy-to-mine ore and the increasing cost of beneficiation are the two major problems that plague mining companies. Therefore, how to adopt suitable beneficiation methods and reduce the cost of beneficiation has become an urgent problem for enterprises.

Mining enterprises in order to achieve the best ore beneficiation effect, the selection of beneficiation process flow, can be a good way to reduce the cost of beneficiation. At the beginning of the process design, the selection should be combined with the characteristics of the ore to design a suitable and efficient beneficiation process. At the same time, because of the energy-saving and environmental protection requirements, energy-saving and environmentally friendly beneficiation process technology should be used to reduce energy consumption and environmental pollution, and reduce the cost of beneficiation.

First, for the ore by characteristics can be mainly divided into the following:

1、Physical characteristics of the ore

The physical characteristics of the ore are mainly divided into color, shape, texture, hardness, magnetism, density, etc.. According to the physical characteristics of the ore can choose different beneficiation methods. In mineral density differences in ores such as barite, hematite, asbestos, mica, kaolin, etc., can use heavy media for beneficiation; strong magnetic magnetism of magnetite, magnetic pyrite, semi-pseudomorphic hematite and some ilmenite, chromite, weak magnetic hematite, rhodochrosite often use magnetic separation method; with color, texture, shape, luster and other appearance characteristics of fluorite, talc, wollastonite, silica The fluorite, talc, wollastonite, silica, lithium ore, quartz, potassium feldspar, etc. are often sorted by photoelectricity.

2, the chemical characteristics of the ore

Different ores have different chemical characteristics, such as composition, acidity and alkalinity. For example, copper oxide ore is often separated - flotation method, gold ore such as amalgamation, cyanidation, thiourea, high temperature chlorination and other gold extraction methods.

3、Structural characteristics of the ore

Ore structure refers to the characteristics of the mineral particles in the ore, that is, the shape of mineral particles, the relative size, mutual embedding relationship or mineral particles and mineral aggregates of the embedding relationship. Such as leaching copper-sulfur ore, the use of priority flotation process, copper flotation tailings to be re-flotation of sulfur.

4、The environmental characteristics of the origin of the ore

Different types of ore formed in different environments of origin, such as Yuanshanzi nickel-molybdenum ore genesis type for sedimentary metamorphic hydrothermal transformation type, according to the characteristics of the ore selection of rock crushing, roasting, plus chemical flotation methods; such as Gansu Sunan Huashugou mirror iron mountain and Sichuan Baiyu gluttonous village sedimentary barite ore and hydrothermal barite ore with sulphide ore, fluorite, etc., in addition to the use of heavy selection method, but also flotation methods for separation.

Ore pre-selection pre-selection experiment

Beneficiation experiments are an important basis for developing the correct beneficiation process and determining the beneficiation equipment, through which the beneficiation experiments can optimize the beneficiation process, beneficiation process and reduce the cost of beneficiation. When conducting the beneficiation test, a reasonable test plan should be formulated according to the ore characteristics and beneficiation requirements, optimize the test process and improve the efficiency and accuracy of the test. In the test process, the following points should be noted:

1、The experimental samples should be selected as representative samples in the ore body to ensure the accuracy and reliability of the experiment.

2. The experiment should simulate the actual production working conditions as far as possible.

3. The experimental data should be counted and analyzed to optimize the beneficiation process parameters and equipment and improve the beneficiation efficiency and recovery rate.

How to choose ore dressing equipment

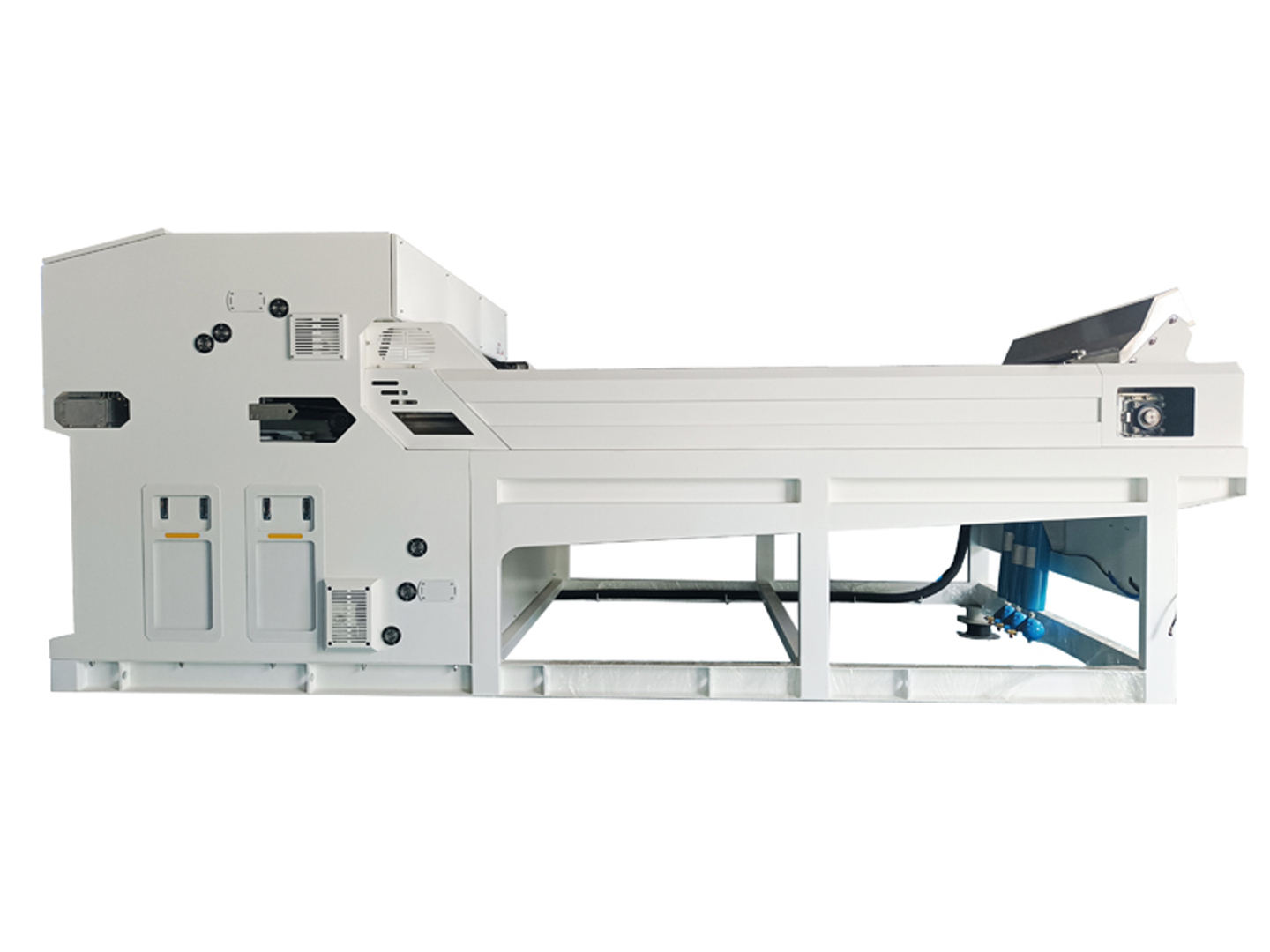

Ore sorting equipment is the key equipment of the beneficiation process, in the selection of equipment, we should fully consider the characteristics of the ore and the requirements to choose the right equipment, in the process of selecting equipment to give priority to performance and cost, but also to consider the service life of the equipment, wearing parts and operation and maintenance costs and other factors. At the same time the manufacturer selection is also more important, whether it is professional to provide mining equipment. For example, specializing in the research and development, production of photoelectric mineral processing equipment of the famous German photoelectric.

Develop a reasonable beneficiation process

The development of a reasonable process in the beneficiation process is the key to ensure the beneficiation effect and reduce the cost of mineral processing. Reasonable control of each link can well reduce the loss and operation and maintenance costs. Specific measures such as

1. Reduce the overload and wear of equipment.

2. Strictly control the operating parameters of mineral processing equipment.

3. for different equipment to develop a scientific and reasonable maintenance plan, regular inspection and maintenance. It can effectively improve the service life of the equipment.

To sum up, reduce the cost of mineral processing and mineral processing process to start from multiple directions and angles, including not only a reasonable mineral processing process, suitable equipment, control of the beneficiation process, rigorous mineral processing experiments and so on. Only a combination of factors can ultimately achieve the reduction of mineral processing costs and the sustainable development of mining enterprises.