Subscribe to our newsletter and always be the first to hear about what is happening.

Intelligent sorting of tailings, get rid of "useless", Meide Optoelectronics realize the value of tailings regeneration!

May 06, 2023Intelligent sorting of tailings, get rid of "useless", Meide Optoelectronics realize the value of tailings regeneration!

In order to implement the "14th Five-Year Plan" and respond to the 20th National Congress report, it is pointed out that the green transformation of the development mode, establish and practice the concept of green water and green mountain is the silver mountain. In order to respond to national policies and development needs, mining enterprises to enhance the use of mineral resources and economic benefits, reduce environmental damage and impact, and ultimately achieve the green mine, intelligent mine construction, and ultimately become the direction of future development of mineral resource-based enterprises.

Among them, as mining resources mining, beneficiation process of industrial solid waste tailings, is a mining enterprises the most headache a difficult point. How to turn waste into treasure? Get rid of industrial solid waste "useless" title, to achieve the recovery of sorting and reuse, sorting is particularly important.

For the tailings generated by different beneficiation methods, the use of targeted ways to deal with, can effectively improve the utilization of ore resources, such as magnetic separation, re-election of the particles after the tailings, such as metal ore can be pre-enriched by way of sorting higher than the economic grade; for non-metallic ore for the composition of the minerals, through the way of sorting, according to the type of ore sorting, and finally achieve the purpose of use. In this regard, sorting has become an essential part of the process.

Today, we will mainly talk about a representative kind of tailings - tungsten tailings. Due to the low grade of tungsten ore, mostly around 0.1%~0.7%, a large amount of tailings are generated during the beneficiation process, accounting for up to 90% of the original ore, most of which are not effectively utilized and are mainly stored in tailing ponds or mine backfills, which not only waste resources, but also occupy land, pollute the environment and endanger health. The annual output of tungsten tailings in China alone is about 400,000t. Improving the overall utilization of tungsten tailings is conducive to promoting the construction of tailings-free mines, which not only improves the added value of tungsten ore resources but also improves the mine environment, and is the future development direction of comprehensive utilization of tungsten tailings.

Tungsten Tailings

The main components in tungsten tailings are oxides of silicon and aluminum, and contain calcium, which are more similar to traditional construction materials and can be used as construction aggregates. However, there are some quartz and flint with alkali activity inside, and there is a risk of alkali aggregate reaction. After sorting and processing, throwing out the quartz and flint in it, it can be used as high standard construction aggregate for large projects, which greatly enhances the utilization and value of tungsten tailings. At the same time, there is also a part of the aggregate, due to the influence of the site water, there will be organic matter, mud lumps, silt and other substances, if made into aggregate, will also affect the overall quality, also need to be sorted, the organic matter and high mud content of the ore thrown out, to reduce the impact of such impurities on the quality of the aggregate, to improve the overall quality and value of the aggregate.

Promoting the recycling of tailings resources and reducing the amount of tailings is a must to promote the development of green mines. It is also a historic development opportunity for mining enterprises, through the utilization of tailings, the utilization rate of mining resources can be effectively improved.

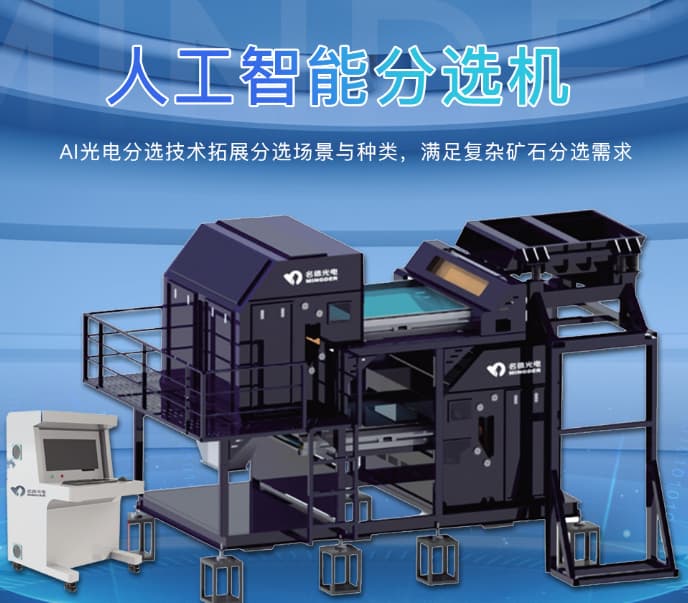

For a long time, Mingde Photoelectric has been around the ore sorting technology research and development, to improve the utilization of ore resources, has been working hard to move forward. In order to expand the scope of application of the equipment, breakthrough photoelectric separation limitations, greatly enhance the scope of ore sorting, for the progress of ore sorting technology, to provide strong support, while the research and development of equipment to fully take into account the complexity of the mining environment, the overall stability of the sorting, yield have a great guarantee. For the green mine, Mingde provide the wisdom.