Subscribe to our newsletter and always be the first to hear about what is happening.

New changes in the industry? A new journey for intelligent ore sorting!

Mar 27, 2023New changes in the industry? A new journey for intelligent ore sorting!

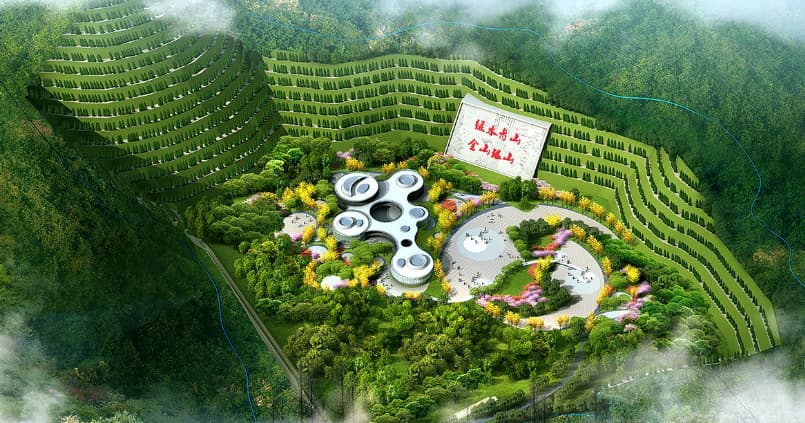

In recent years, with the vigorous promotion of the state, the transformation and upgrading of traditional industries ushered in huge development, especially in mining enterprises, especially prominent in the process of upgrading mines, mainly to create intelligent mines, green mines as the direction of development, intelligent, intelligent, mechanized as the focus, to break the deadlock of mine development. To further improve the utilization rate of mining resources, improve the economic benefits of mining enterprises, reduce the environmental damage in mining, and ultimately achieve the construction of green mines!

Ten years of exploration of intelligent sorting, to promote the new development of industrial mining sorting

In recent years, with the development of social and economic development and the formulation of national policies, the construction of green mines around the six evaluation indicators of environmental protection, resource development, resource utilization, energy saving and emission reduction, technological innovation and enterprise construction. How can mining enterprises break the existing dilemma? Promote the development of intelligent and wise mines, and make a good strategic layout of green mines.

Around solving the problems of low economic grade ore enrichment, reducing the dosage of flotation drugs, handling waste ore after grinding and flotation, and reducing the power consumption of sorting equipment, we can effectively improve the evaluation indicators, mainly reflected in the improvement of the beneficiation link, to drive the construction of green mines.

Photoelectric sorting after recent decades of development, whether in the technical development or production applications, there is a full development, in solving the existing beneficiation problems have significant significance. Such as in the mining of low economic grade ore, through the sorting of pre-enrichment, to enhance the selected ore grade; also through the sorting of pre-throw waste rock, reduce the amount of ore into the flotation, saving flotation costs and the use of pharmaceuticals; grinding flotation waste slag problem, because photoelectric sorting into the larger particles of ore, throwing waste tailings can be used as building stone or mine backfill; existing tailings processing problems, can be through photoelectric sorting equipment Throwing out the useless waste stones in it, enhance the economic value of the tailings.

Ore sorting industry layout, opening a new change in China's ore sorting

Established in 2014, Mingde Optoelectronics has been rooted in the concept of "leading technology and innovation" since the beginning of its establishment. We have launched ore colour sorter, artificial intelligence sorter, X-ray intelligent sorter, heavy duty machine and foreign body exclusion robot, etc. We have been laying out to make our own photoelectric sorter and mining automation equipment. Helping to achieve intelligent, mechanized and green sustainable development of ore sorting.

Intelligent ore sorting equipment, laying the intelligent benchmark of the industrial mining industry

How to lay the ore photoelectric sorting intelligent process? The next detailed answer for you, Mingde photoelectric sorting equipment integration of the current stage of cutting-edge artificial intelligence sorting technology, with high-end spare parts. As the equipment specialised in ore sorting, in the beginning of research and development, design and production, after repeated arguments, experiments to deal with the complex mining environment, taking into account the corrosion resistance, high pollution, high dust, parts damage and other issues.

The technical level introduces deep convolutional neural network (CNN) and other artificial intelligence means for material image analysis, recognition and comparison, and through CNN local connection, weight sharing and multiple convolutional kernels, the recognition accuracy of non-mass data training is guaranteed through non-mass data, using data migration learning technology and industrial image sample enhancement technology, using AI photoelectric sorting technology to automatically extract the object's surface multi-dimensional features, such as texture, colour, lustre, texture, shape, etc. to establish a database, identify subtle differences in the sorted ore through multi-dimensional comparison, and accurately sort out the good and bad ores from the selected ore.

In the application of industrial ore sorting, and achieved good results, especially in talc, wollastonite, silica slag, pebbles, gold ore and other ores, these ores are mainly reflected in the complex sorting, waste rock and concentrate characteristics of small differences, sorting precision requirements, high characteristics, in other ores such as: fluorite, silica, calcium carbonate, lithium mica, lithium pyroxene, phosphate ore, quartzite, potassium feldspar and other metal, non-metallic ores also There is a wide range of applications.

With the investment of Mingde's photoelectric technology research and development, it has broken through the limitations of traditional photoelectric colour separation and expanded the application scenario of photoelectric ore separation and the types of ore species that can be selected; at the same time, under the conventional photoelectric sorting particles, it has also broken through and launched a special heavy machine with large particles and high output, which can sort ores of 3-8cm and 8-15cm. Mingde has been in the ore photoelectric sorting help forward.

Mingde photoelectric for willing to work together with friends from all walks of life, and jointly promote the road of ore photoelectric sorting forward, for mine intelligence, mechanization, green sustainable injection of Mingde power!