Brucite: Characteristics, Distribution, Uses and Beneficiation Methods!

Jun 29, 2024

Brucite: Characteristics, Distribution, Uses and Beneficiation Methods!

Jun 29, 2024

Brucite, also known as magnesia, is a hydroxide ore. Its main component is magnesium hydroxide. It is one of the minerals with the highest magnesium content in nature.Brucite is a rare and precious magnesium-rich non-metallic mineral. It belongs to the trigonal crystal system and has a variety of appearances. It is usually flaky or fibrous aggregates. It is white, light green or colorless in color. It has a glassy luster on the fracture, a pearly luster on the dissociation surface, a silky luster on the fibrous one, a flexible thin sheet, and a brittle fibrous one.

Brucite is a layered hydroxide that is widely distributed in nature and is widely distributed. It is mainly distributed in countries and regions such as China, Canada, and the United States. In addition, brucite mines are also distributed in Russia, North Korea, Norway and other countries.

Canada and the United States are among the world's major producers of brucite. Canada's brucite is mainly distributed in Ontario, Quebec and other places, while the United States' brucite resources are mainly distributed in Nevada, Texas and other places.

China's brucite resources are mainly distributed in the western region, such as Xinjiang, Qinghai, Tibet, Sichuan and other provinces and cities according to sedimentary strata. In addition, some brucite resources are also distributed in Northeast China, North China, Central China and other regions. Specifically, the total proven reserves of brucite resources in China have exceeded 25 million tons, among which Fengcheng, Liaoning, Ji'an, Jilin, Ningqiang, Shaanxi, Qilian Mountains, Qinghai, Shimian, Sichuan, Xixia, Henan and other places are important brucite production areas. In particular, Fengcheng, Liaoning, has the richest brucite resources in China, with reserves of up to 10 million tons. The proven reserves of brucite in Ningqiang, Shaanxi are 7.8 million tons; the proven reserves of brucite in Ji'an, Jilin are 2 million tons.

Judging from the ore quality, scale and mining conditions of brucite, Liaoning Province has the best brucite resources in China. The brucite ore in Kuandian is close to the theoretical mass of brucite (%): MgO 66.44, H2O 29.00, SiO2 0.80, Al2O3 0.21, Fe2O3 0.73.

Brucite has a variety of uses and applications, from industrial processes to environmental and technical applications. The following are some of the main uses of brucite:

(1) Extraction of magnesium and magnesium oxide

The magnesium oxide content in brucite ore is high and has few impurities; the decomposition temperature is low; the volatile matter produced when heated is non-toxic and harmless, so magnesium and magnesium oxide and other products can be extracted from brucite.

(2) Dead-burned magnesia

Dead-burned magnesia made from brucite has the advantages of high density (greater than 3.55g/cm3), high refractoriness (greater than 2800℃), high chemical inertness and high thermal shock stability. It is widely used in the production of key parts such as furnace linings and furnace bottoms, especially in the steel and non-ferrous metal smelting industries.

(3) Light magnesium oxide

Light magnesium oxide is extracted from low-grade brucite rock by chemical methods.

(4) Fused periclase

It is a special pure product required by high-tech electronic products. The periclase aggregate refined by brucite by electric fusion has high thermal conductivity and good electrical insulation, and the product life is increased by 2~3 times.

(5) Chemically pure magnesium reagent

Mainly use the electric heating method to extract metallic magnesium and prepare chemically pure reagents such as MgCl2, MgSO4, and Mg(NO3)2. At the same time, it can be used to make high corrosion resistance agents and is widely used in the electroplating industry.

(6) Reinforcement materials

Bruceite can be used as a substitute for chrysotile in some fields, and is used in mid-range thermal insulation materials such as microporous calcium silicate and calcium silicate board. The basic formula is: diatomaceous earth, lime slurry, water glass, bruceite. The content of bruceite is 8%~10%. The product has high whiteness, beautiful appearance and low bulk density.

At the same time, due to the repeatability, corrosion resistance, high hardness and good mechanical strength of brucite, it can be used as an additive to improve the strength and hardness of cement and enhance the durability of concrete. In addition, brucite can also slow down the gel phase generation rate of concrete, thereby delaying the degradation process of the structure.

(7) Papermaking filler

Brucite has high whiteness, good flaking, strong adhesion and poor water absorption. Using it in combination with calcite as a papermaking filler can change the papermaking process from acid method to alkali method and reduce the pollution of slurry water.

(8) Flame retardant

As a fibrous variant of brucite, fibrous brucite contains about 30% of crystal water and has a low decomposition temperature (450℃, static about 350℃). It is widely used in flame retardant products with its good heat resistance and flame retardancy.

(9) Environmental protection application

Due to its composition characteristics, brucite presents moderate alkalinity and can be used as an acidic wastewater neutralizer. It is used to purify acidic substances in wastewater and waste gas, effectively reduce pollutants such as acid rain and acidic waste gas, and thus protect the environment. In the process of neutralizing acidic substances, brucite also has a certain buffering capacity.

(10) Water treatment

Brucite also plays an important role in the field of water treatment. It can be used to remove hardness ions in water, prevent the formation of scale, and protect water treatment equipment. In addition, brucite can also be used for deoxygenation, adjusting the pH value of water and buffering water quality, thereby improving and optimizing water quality.

In general, brucite has a wide range of uses, covering many fields such as construction, metal smelting, chemistry, water treatment, medicine, environmental protection and food industry.

In order to improve the utilization value of brucite, we generally use brucite of different grades. Generally speaking, brucite is used as a raw material for magnesium salts, basic magnesium salts, magnesium oxide and other products, and the grade of brucite is relatively high. In some specific applications, such as making refractory materials and flame retardants, the grade requirements for brucite may be relatively low.

In order to improve the grade of brucite, we can use crushing, dissociation and sorting to sort out the associated minerals in brucite to achieve the purpose of improving the grade of brucite.

Common associated minerals in brucite are mainly serpentine, calcite, dolomite, magnesite, magnesium silicate minerals, periclase, diopside and talc.

Specifically, serpentine in the associated mineral is a hydrated magnesium silicate mineral, usually yellow-green or dark green, with a glassy or silky luster. Calcite is a calcium carbonate mineral with a glassy luster and low hardness. Dolomite is a carbonate mineral, similar to calcite, but with a higher magnesium content in its chemical composition. Magnesite is a magnesium carbonate mineral with a glassy luster and low hardness. By taking advantage of the surface feature differences between its associated minerals and brucite, we use photoelectric sorting equipment for sorting, which can effectively remove most of the dissociated associated minerals, improve the grade of brucite ore, and create higher economic value for mining companies.

For some brucite mining companies, after long-term mining, there is no good sorting method in the particle ore stage, resulting in about 30~40% of the concentrate with a grade of more than 60 in the tailings pond. With the development of artificial intelligence and photoelectric mineral processing technology in recent years, the technical level and equipment maturity have been widely recognized by the market and applied in the sorting of brucite tailings. In particular, Mingde Optoelectronics' artificial intelligence sorting equipment can accurately identify associated minerals such as brucite, serpentine, and dolomite, and sort them by taking pictures, training, learning, and modeling the ore to be selected.

MINGDE Optoelectronics is an enterprise focusing on ore sorting technology. The artificial intelligence sorting machine developed by it is applied to the sorting process of brucite. The equipment uses advanced image recognition technology and artificial intelligence algorithms to efficiently and accurately grade the quality of brucite, remove impurities, and improve the quality of the original ore. In summary, MINGDE Optoelectronics' artificial intelligence sorting machine plays a key role in the sorting of brucite. It optimizes the traditional mineral processing process through intelligent technology, improves the sorting accuracy and efficiency, and contributes to the sustainable use of resources.

What are the Factors that Affect Ore Sorting?

Jun 12, 2024

What are the Factors that Affect Ore Sorting?

Jun 12, 2024

Ore Cost Calculation Method

Jun 24, 2024

Ore Cost Calculation Method

Jun 24, 2024

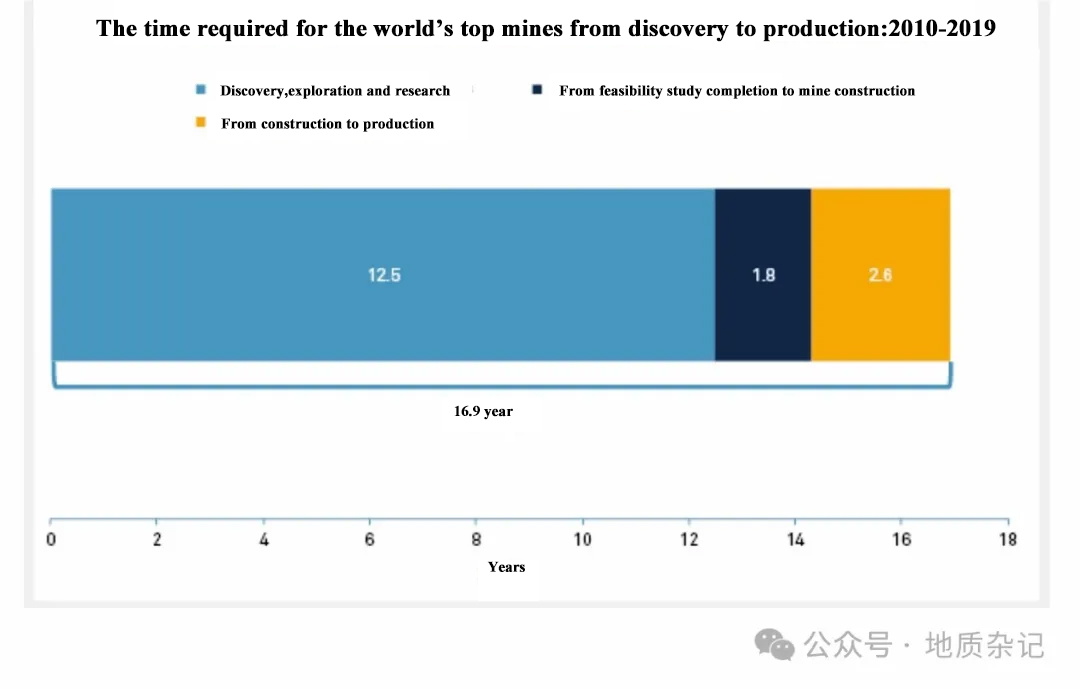

The Average Time Required for the World's Top Mines from Discovery to Production is 16.9 Years

Jun 25, 2024

The Average Time Required for the World's Top Mines from Discovery to Production is 16.9 Years

Jun 25, 2024

Brucite: Characteristics, Distribution, Uses and Beneficiation Methods!

Jun 29, 2024

Brucite: Characteristics, Distribution, Uses and Beneficiation Methods!

Jun 29, 2024

The Importance of Ore Pretreatment and Enrichment

Jul 13, 2024

The Importance of Ore Pretreatment and Enrichment

Jul 13, 2024