Subscribe to our newsletter and always be the first to hear about what is happening.

Pegmatitic Quartz Pretreatment Strategy and Challenges as a Source of High Purity Quartz Sand

May 29, 2024Pegmatitic quartz's Less impurities, stable quality, low fluid inclusion content advantages make it a vital raw material for the production of high-purity quartz sand.

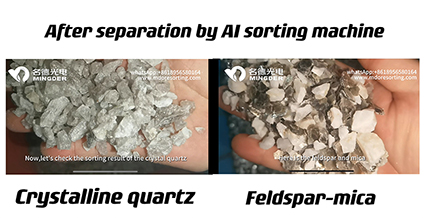

A major obstacle in the pretreatment stage is that, while conventional pretreatment will blow off some of the light mica through wind separation, quartz and feldspar, which are sometimes both porcelain white, are difficult to separate efficiently using physical separation (such as gravity, magnetic separation, or electric separation) due to their similar properties.

The Mingde artificial intelligence visible light sorting machine solves the challenge of sorting feldspar mica from pegmatitic quartz with precision by modeling and differentiating distinct features of the mineral surface.

1. Discard the thin mica after the first air toss.

2. Modeling and sorting: construct three different mineral models: quartz-feldspar associated ore, feldspar/mica, and crystalline quartz,industrial computer will take a comprehensive self-deep learning of the surface features of the three models and stock the record. To achieve the effect of real-time sorting during mass feeding and production, the equipment's industrial computer retrieves the model and matches the necessary impurities and crystal quartz,separation happened in real-time.Learn more about our experiment and project site,check here.

Our AI sorting solution is currently being used by the majority of top-tier HPQ organizations.Furthermore, our AI sorting technology is extensively used for talc, brucite, phospate,gypsum and other difficult minerals in addition to being ideal for the separation of pegmatite quartz.Being a significant contributor to the green mining sector makes us proud.