Subscribe to our newsletter and always be the first to hear about what is happening.

Photoelectric Separation: Helping to Enrich the Grade of Gold Mines

Jul 27, 2024Gold deposits can be broadly classified into vein gold deposits and placer gold deposits. The vein gold deposits are mainly formed by internal geological forces, mainly by volcanoes, magma, and geological actions; the placer gold deposits are mainly formed by mountain gold deposits exposed on the surface, which are weathered, eroded, and broken into gold sand, gold grains, gold flakes, and gold foam after long-term weathering, erosion, and crushing. Under the action of wind and water flow, they are gathered and deposited in rivers, lakes, and coasts, forming alluvial, alluvial, or coastal placer gold deposits; another part is weathered and eroded to form residual placer gold deposits or slope-accumulated placer gold deposits. The mineralization age of this type of ore is generally relatively long.

According to the associated conditions, my country's gold deposit types can also be divided into gold-bearing quartz veins, gold-bearing pyrite quartz veins, gold-bearing pyrite altered granites, gold-bearing polymetallic sulfide ore quartz veins, gold-bearing oxide ore quartz veins, and gold-bearing tungsten-arsenic ore quartz veins.

The grade of vein gold ore in industrial mining is generally 3~5g/ton, with a cut-off grade of 1~2g/ton, and the grade of placer gold is 0.2~0.3g/m3, with a cut-off grade of 0.05~0.1g/m3. However, the current gold mining in my country is mainly based on vein gold deposits, accounting for about 75%~85%.

At present, gold mines are widely used in jewelry, industry, high-tech and other industries. Due to its scarcity and non-renewable nature, its overall value is relatively high. At present, the gold ore dressing methods are mainly divided into four types: gravity separation, flotation, chemical separation, and photoelectric separation.

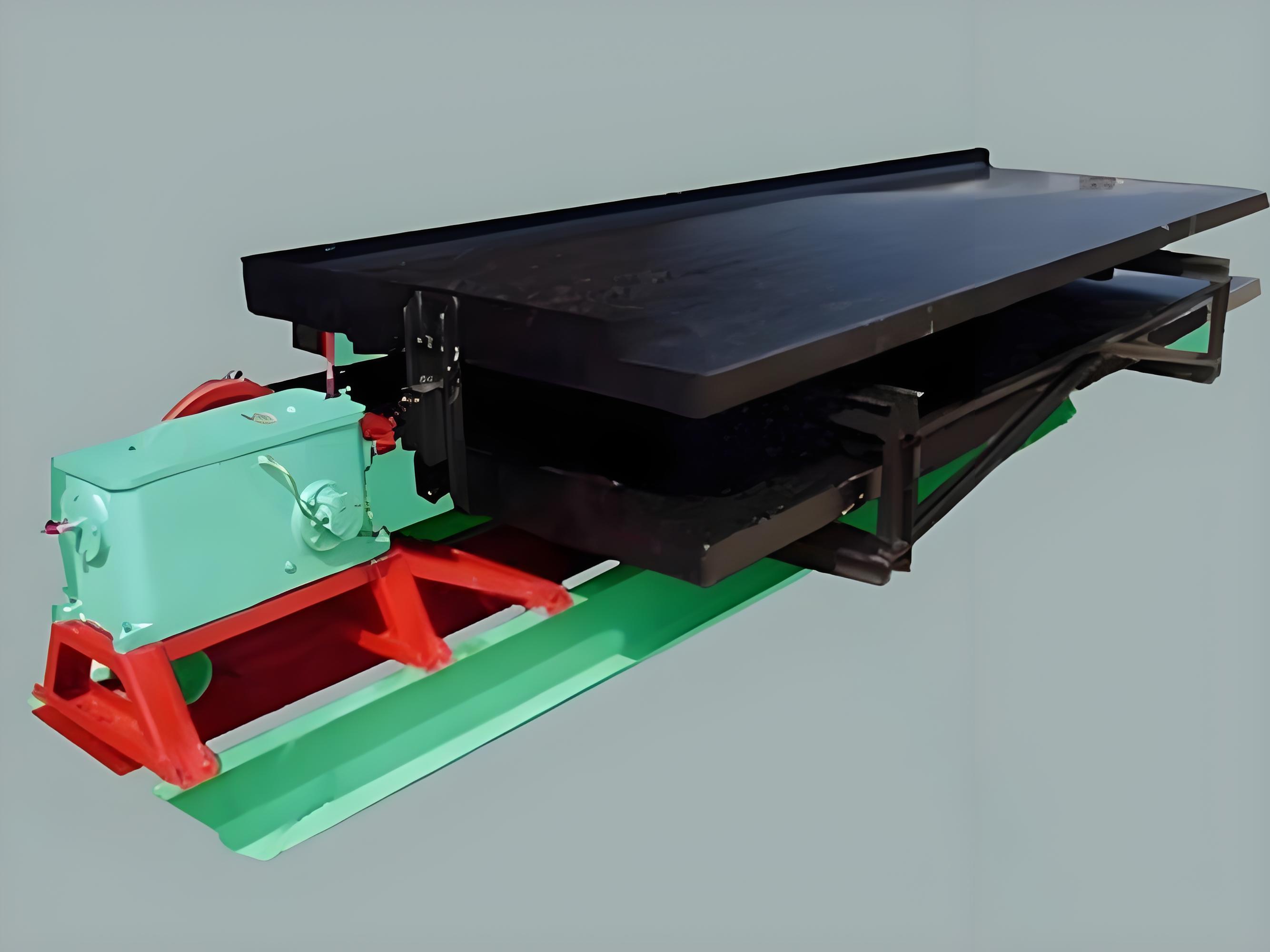

Gravity separation is suitable for coarse gold recovery. It is generally an auxiliary process in gold ore dressing and is used as a pre-selection process before flotation or chemical separation.

Flotation is widely used in rock deposits. There are suction or aeration stirring flotation machines for flotation.

Chemical separation mainly includes amalgamation and chlorination. Amalgamation is mainly suitable for coarse monomer gold, but it is gradually replaced due to its high pollution. Chlorination mainly includes stirring chlorination and percolation chlorination.

The above three separations are conventional gold ore separations. For gold mines with economic mining grade or higher than industrial grade, the separation cost is lower than the economic cost. However, the general situation of gold mines in my country is that there are fewer rich mines and more poor mines. In terms of mining difficulty, there are fewer easy mines and more difficult mines. Most gold mines have a grade of less than 2 grams/ton, which is at or below the critical mining grade. If the above methods are used for direct separation, many gold mines will be lower than the economic mining value.

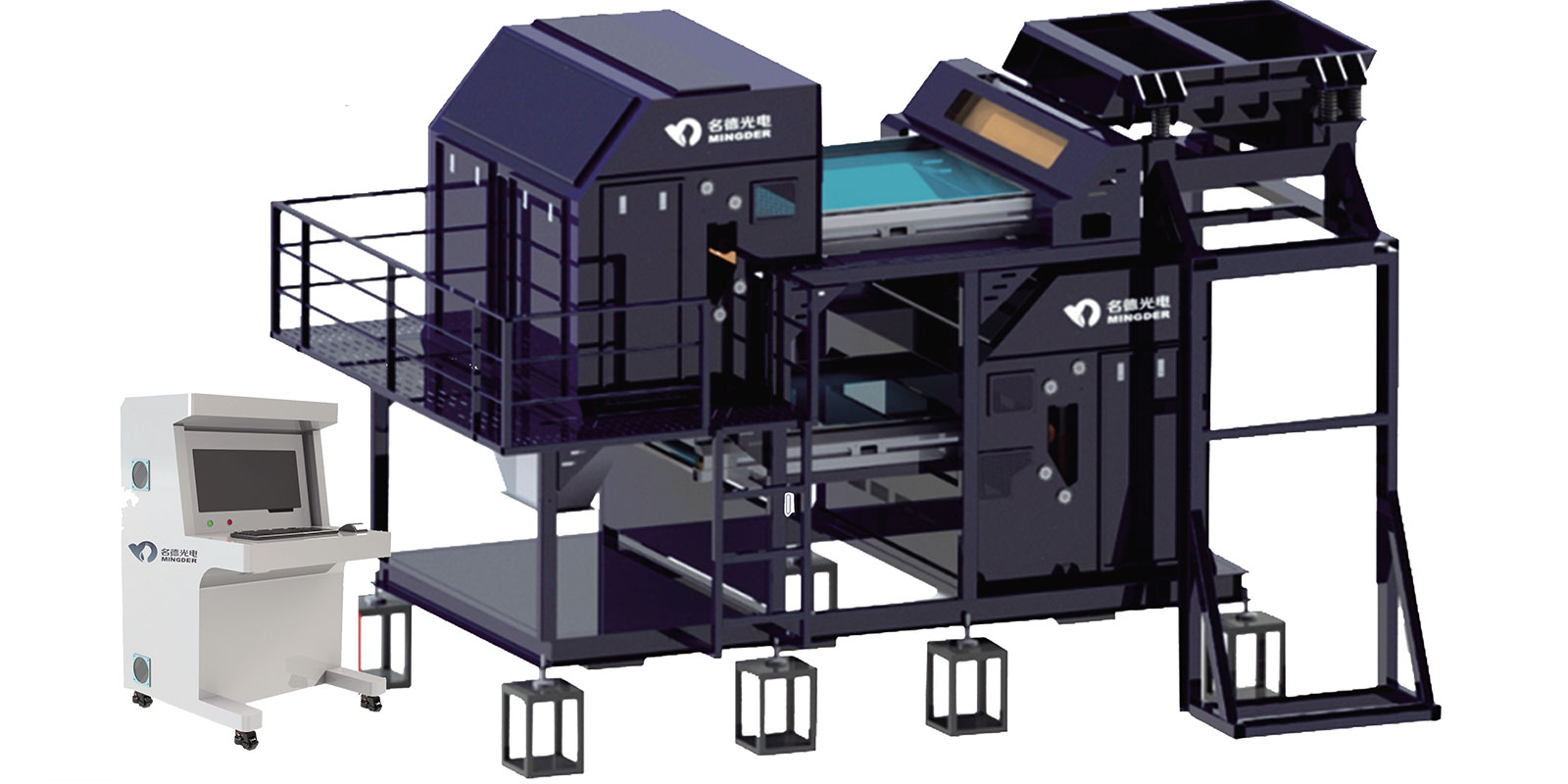

The photoelectric sorting method grasps the pain points and difficulties of domestic gold ore sorting, and uses AI + photoelectric sorting to enrich the gold ore by pre-discarding the gold ore, thereby achieving a higher economic mining grade, and solving the problem of low grade and high sorting cost of domestic gold ore. The working principle is mainly to crush and dissociate the gold ore, and then use the AI sorting machine to establish a multi-dimensional three-dimensional model of the ore. The AI photoelectric sorting machine is used to identify the comprehensive characteristics of the gold ore surface, such as texture, color, gloss, shape, and reflectivity. After the industrial computer is combined with AI technology, the concentrate and waste rock in the gold ore are sorted out, so as to achieve the purpose of gold ore enrichment.

The ore that has passed the AI ore sorting machine only needs normal crushing and dissociation, and the particle size is 0.5cm-10cm, which is about 3-4 times the size of the selected particle size. It can be directly sorted and enriched, and the discarded tailings can be used as materials for various buildings, mine backfill, etc. After enrichment, the gold ore is separated by flotation or chemical separation. Pre-disposal reduces the processing level of the original ore and saves the processing cost of subsequent processes.

For some gold mines below the economic mining grade, AI ore sorting machines can be used to enrich them to the economic mining grade, thereby increasing the utilization value of a large number of low-grade gold mines. AI sorting machines can not only sort gold ore, but also can use AI machines to sort gold associated ores as long as they can be crushed and dissociated, thereby increasing the comprehensive utilization rate of the mine. At the same time, the cost of the AI sorting machine itself

Mingde Optoelectronics AI Ore Sorting Machine has mature technical accumulation for gold ore sorting. It can pre-dispose waste tailings on the premise of enriching gold ore, and the gold grade of the discarded tailings is far lower than the economic mining grade.