Subscribe to our newsletter and always be the first to hear about what is happening.

Sorting and Application of Silica Ore

Jul 16, 2024Silica ore is a non-metallic mineral with silica-rich minerals as the main component, mainly including quartz sandstone, quartzite and other forms. The classification of silica ore is complex and diverse, and can be distinguished according to the environment, composition, structure, etc. of its formation. The application of silica is extremely wide, involving many industries such as glass, ceramics, and refractory materials.

The classification of silica ore can be divided from multiple angles:

1. Classification by organizational structure: It can be divided into crystalline silica and cemented silica. Crystalline silica is mainly composed of quartz particles, while cemented silica is quartz particles combined by siliceous cement.

2. Classification by transformation speed: Silica can be divided into four types according to its transformation speed at high temperature: extremely slow, slow, medium and fast transformation.

3. Classification by density: Silica can also be divided into extremely dense, dense, relatively porous and porous according to its density.

Application of silica ore

Due to its unique physical and chemical properties, silica ore has important applications in many fields:

1. Glass industry: silica ore is an important raw material for glass manufacturing, especially vein quartz, which is the preferred raw material for producing high-quality glass because of its SiO2 content of up to 99%.

2. Ceramic industry: silica ore is used to produce ceramics, especially some ceramic products with special requirements, such as electrical insulation porcelain, chemical corrosion-resistant porcelain, etc.

3. Refractory materials: The high temperature performance of silica ore makes it the preferred raw material for making refractory materials, such as blast furnace refractory materials used in steel smelting.

4. Abrasive industry: silica ore is also widely used in the abrasive industry. Due to its high hardness, it can be used in various grinding and polishing processes.

The mining of silica ore is mainly carried out in open-pit mode, and the ore dressing and purification process includes steps such as scrubbing, magnetic separation, flotation, acid leaching and photoelectric separation. These processes are designed to improve the purity of silica and reduce the impurity content to meet the specific needs of different industries.

Silica ore is usually crushed using jaw crushers and cone crushers. The former is suitable for primary crushing, while the latter is used for secondary or finer crushing. The crushed silica enters the grinding stage. Grinding equipment includes ball mills, high-pressure suspension roller mills and abrasive mills, etc. These equipment can grind silica to the required particle size and improve the quality of silica.

Scrubbing is the use of mechanical force and the abrasive force between sand particles to remove film iron, bonding and muddy impurity minerals on the surface of quartz sand. Magnetic separation can remove magnetic minerals such as hematite, limonite and other impurities from scrubbed silica to the maximum extent.

Flotation is mainly used to remove non-magnetic associated impurity minerals such as feldspar, mica, etc. During the flotation process, the chemical conditions of the flotation environment are adjusted by adding flotation agents such as collectors, frothers and regulators to improve the separation efficiency of silica and impurities.

Acid leaching is mainly used to further reduce the iron content in silica, especially for quartz sand with high purity requirements. Acid leaching can make the purity of silicon dioxide reach more than 99.93%.

https://www.mdoresorting.com/mingde-ai-sorting-machine-separate-quartzmicafeldspar-from-pegmatite

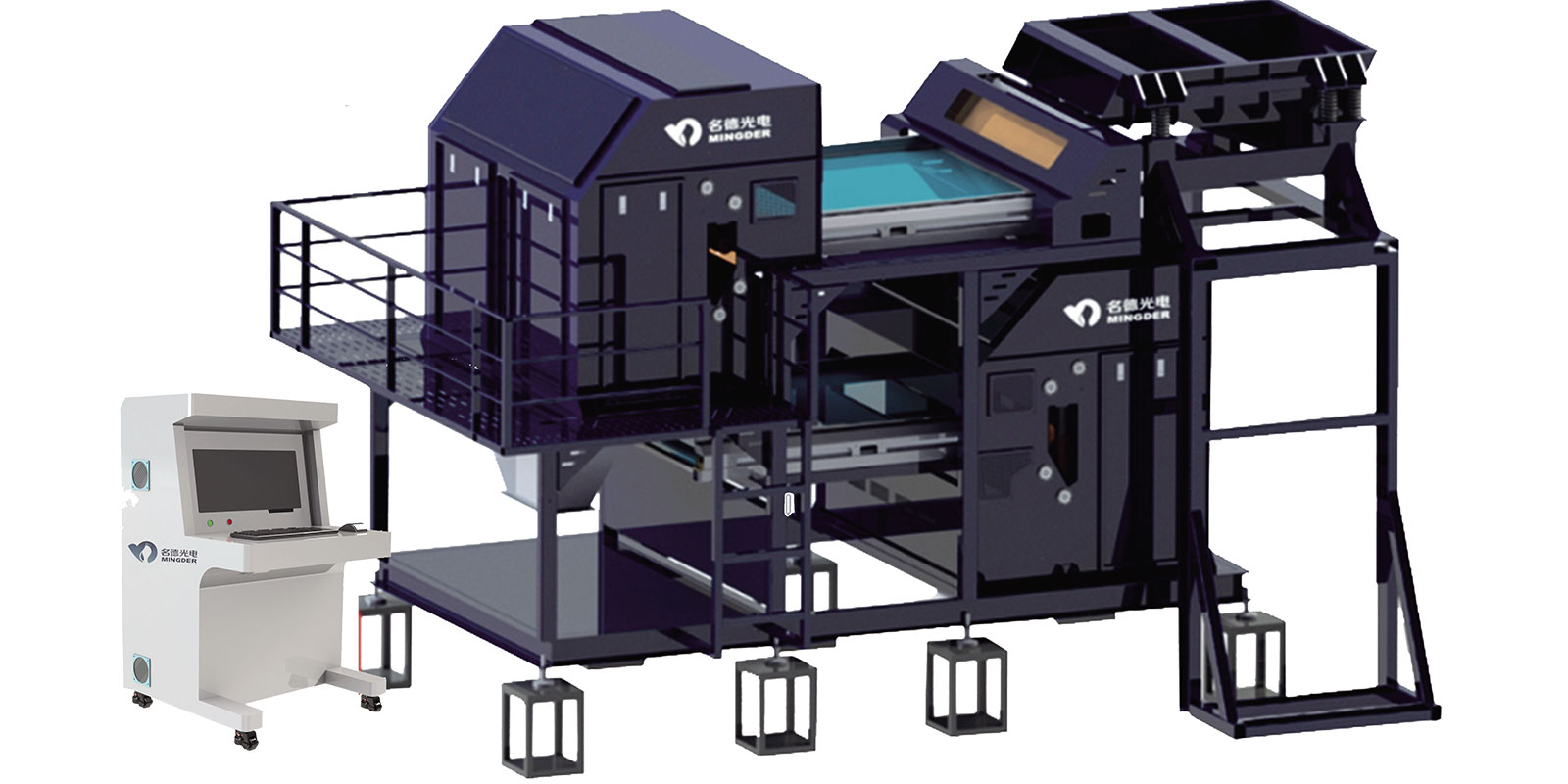

Photoelectric sorting is a technology that uses the surface characteristics of silica ore for identification and sorting. It is suitable for silica ores with obvious or complex color characteristics. Through photoelectric detection technology, heterochromatic granular materials are automatically sorted out, thereby improving the overall quality of silica. It is worth mentioning that Mingde Optoelectronics Technology Co., Ltd. is the first to introduce artificial intelligence technology in the field of visible light photoelectric sorting, which can sort more categories of ores. In silica ore sorting, the color, gloss, texture and texture of the ore surface can be used to distinguish the silicon in the ore from the feldspar of the same color. The sorting effect is more accurate than that of the color sorter.

Pre-sorting usually includes processes such as scrubbing, magnetic separation and flotation, while auxiliary processes include adding pre-sorting processes after crushing, and improving the quality of the ore entering the mill through pre-waste treatment, improving the production efficiency of subsequent processes and reducing production costs.

In summary, silica ore, as an important non-metallic mineral, not only has a wide variety of types, but also has a wide range of industrial application value. The continuous deepening of research on its mining and purification technology will help to better realize its potential in various fields. With the advancement of science and technology, the utilization of silica ore in the future may be more efficient and environmentally friendly.