Subscribe to our newsletter and always be the first to hear about what is happening.

Technical Advantages and Market Applications of AI Intelligent Ore Sorting Machine

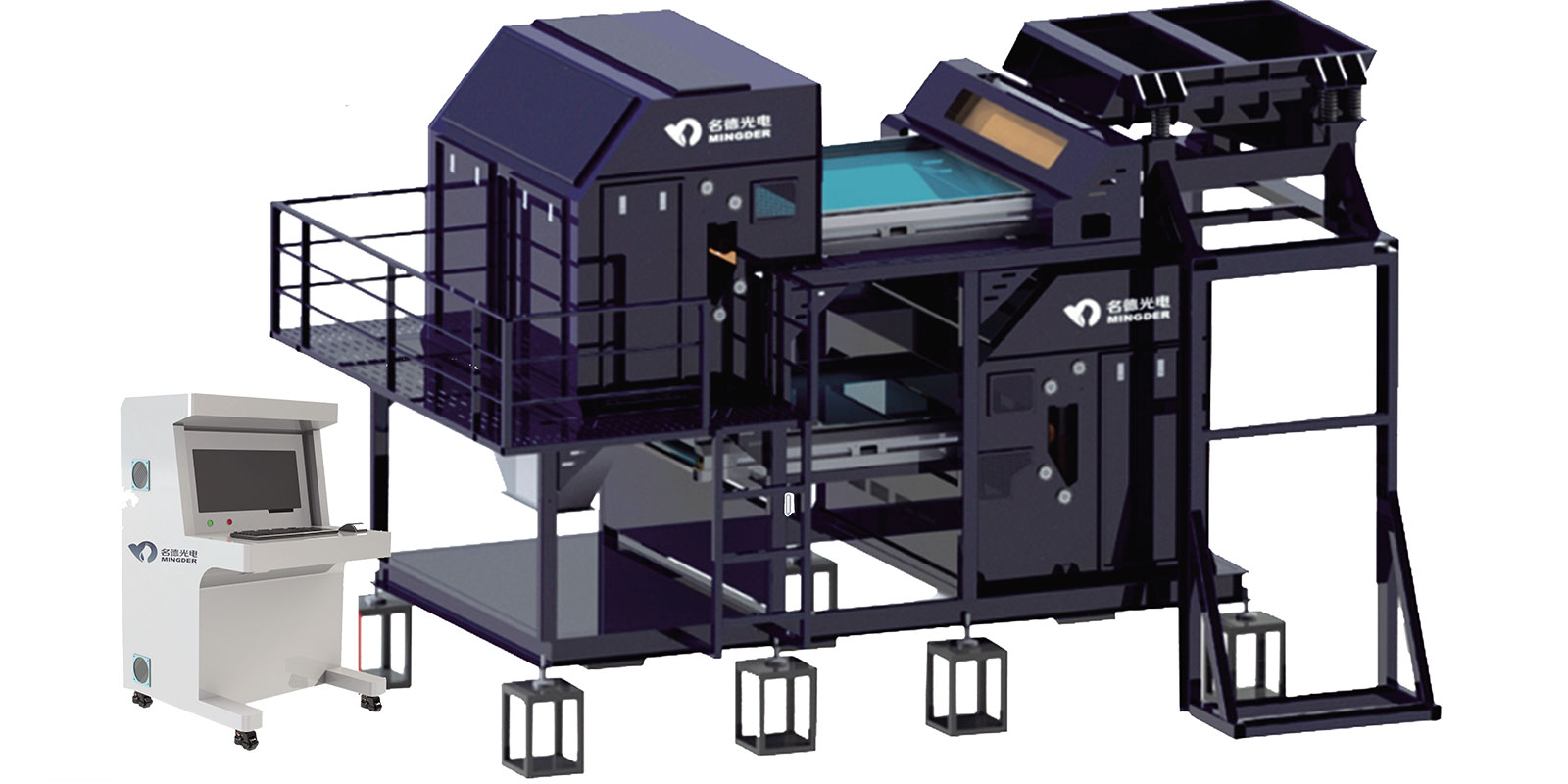

Aug 01, 2024AI intelligent ore sorting machine is a high-tech equipment that uses artificial intelligence technology to sort ore. It integrates cutting-edge mineral processing technology through a high-speed crawler design, and can realize the sorting application of large-particle, high-yield ores. This type of sorting machine is usually composed of a material feeding system, an optoelectronic system, a control system, a sorting system, etc., which can automatically extract the multi-dimensional characteristics of the ore, such as texture, shape, color, texture, gloss, etc., and identify the subtle differences in the sorted ore through multi-dimensional comparison to achieve accurate sorting.

https://www.mdoresorting.com/mingde-ai-sorting-machine-separate-quartzmicafeldspar-from-pegmatite

At present, AI intelligent ore sorting machines have been used in multiple types of ores, including but not limited to talc, wollastonite, silicon slag, gold ore, etc. These devices perform well on ores with complex sorting and small differences in waste rock and concentrate characteristics, helping to improve the comprehensive utilization rate and economic value of the ore. For example, in the intelligent sorting of talc ore, the application of AI technology not only improves the economic benefits of talc ore, but also promotes the transformation and upgrading of the mining industry towards intelligence and greening.

https://www.mdoresorting.com/ai-copper-oxide-ore-sorter-ai-ore-sorting-machine

https://www.mdoresorting.com/ai-copper-oxide-ore-sorter-ai-ore-sorting-machine

With the continuous advancement of science and technology and the increasing demand for high-efficiency, low-cost, and environmentally friendly mineral processing technologies in the mining industry, the market prospects of AI intelligent ore sorting machines are broad. The research and development and application of these devices help to improve the utilization rate of mineral resources, reduce production costs, improve production efficiency, and conform to the development trend of green mining. Therefore, AI intelligent ore sorting machines are becoming one of the key technologies for the modernization and intelligent transformation of mining.

AI intelligent ore sorting machines rely on a variety of sensors to obtain key information about ore during the ore sorting process, which is essential for the effective classification of ore. The following are some of the main types of sensors and their functions:

1. High-resolution camera: used to capture the appearance characteristics of ore, such as color, texture, gloss, and morphology. These image data are used to train machine learning models to intelligently identify different types of ores.

2. Spectral sensor: By analyzing the spectral signals emitted or reflected by the ore, the spectral sensor is able to provide information about the chemical composition of the ore. This information helps to distinguish ores with similar appearance but different chemical compositions.

3. X-ray source and transmission plate: For those ores with unclear surface features but density differences, X-ray sensors can penetrate the ore and detect its internal structure, thereby achieving density-based sorting.

4. Sensors or transmission plates: These sensors usually work with light sources and background plates to perform high-definition imaging of the ore and convert these images into electrical signals for analysis by the electronic control system.

5. Other monitoring sensors: used to monitor various data in the mineral processing process in real time, such as slurry concentration, foam layer thickness, bubble size, etc. These data are very important input information for the intelligent control system.

The combined use of these sensors allows the AI intelligent ore sorting machine to sort ore at an automated and intelligent level, greatly improving the sorting efficiency and accuracy. Through the collection and analysis of real-time data, the sorting machine can adapt to the characteristics of different ores, optimize the sorting process, reduce labor costs, and improve the overall economic benefits.

Compared with traditional ore sorting equipment, AI intelligent ore sorting machines show significant technical advantages, mainly in the following aspects:

1. Multi-dimensional feature recognition: AI intelligent ore sorting machines can automatically extract multi-dimensional three-dimensional features of objects, including texture, shape, texture, color and gloss, etc. These features are usually beyond the recognition range of traditional equipment, thereby improving the accuracy and flexibility of sorting.

2. High efficiency and wide applicability: Due to the ability to recognize richer features, AI intelligent ore sorting machines can handle a wider range of types of ores and complete them in a single sorting step, significantly improving the net selection rate, which is more than 80% higher than traditional color sorters.

3. Data-driven learning ability: AI technology allows equipment to process non-massive data through data migration and image enhancement technology, and maintain high recognition accuracy even when industrial and mineral material data is limited. The equipment can continue to learn based on deep learning models to further optimize the sorting effect.

4. Environmental friendliness and cost saving: AI intelligent ore sorting machine can remove useless materials in the pre-waste stage, reduce the amount of materials and costs of subsequent processes, and reduce environmental damage and waste disposal problems, which will help realize the green and intelligent transformation of mines.

5. Highly integrated intelligent system: Combining advanced technologies such as artificial intelligence, big data, and cloud computing, intelligent mineral processing technology realizes real-time monitoring, data collection, and remote control of the mineral processing process, improving management level and production efficiency.

6. Energy saving and environmental protection: Intelligent mineral processing technology achieves energy saving and consumption reduction by optimizing processes and parameters, reduces tailings discharge, and promotes the recycling of mineral processing wastewater to improve resource utilization.

7. Easy to expand and maintain: With modular design, intelligent mineral processing technology facilitates the expansion and upgrading of later functions to meet the needs of continuous improvement in mineral processing production.

In summary, the technical advantages of AI intelligent ore sorting machine include highly intelligent operation, low energy consumption, a wide range of adaptability, and the ability to customize machine models and supporting equipment according to different types of minerals and industrial and mining production needs. These devices can operate stably in harsh environments such as high dust, high pollution, and high corrosion, meeting the demanding requirements of the mining industry. In addition, they can continuously improve the sorting effect through learning mode, realize remote debugging, intelligent monitoring, remote service, and remote software upgrade, greatly improving the efficiency and accuracy of ore sorting.

These advantages show that AI intelligent ore sorting machines represent a new trend in mining sorting technology and are expected to lead the industry to a more efficient, environmentally friendly and intelligent direction.

Given these technical advantages of AI intelligent ore sorting machines, the machines have a very good response in market applications. According to the latest market application situation, these intelligent sorting systems have achieved optimal configuration and efficient utilization of mineral resources through real-time monitoring, data analysis, and intelligent decision-making. They can improve the utilization rate of mineral resources, reduce production costs, and ensure the safety of the mineral processing process.

The development trend of intelligent mineral processing technology shows that data acquisition and processing technology, artificial intelligence and machine learning technology, automation and robotics technology, and cloud computing and big data technology are being widely used in the field of mineral processing to improve mineral processing efficiency, reduce costs, and reduce resource waste. The integration of these technologies enables AI intelligent ore sorting machines to achieve a higher level of automation and intelligent operation in complex mining environments.

In the market, the application cases of AI intelligent ore sorting machines include successful implementation in copper, gold and iron ore beneficiation plants, which prove the effectiveness of intelligent beneficiation systems in improving the utilization rate of mineral resources and reducing production costs. With the continuous advancement of science and technology, it is expected that AI intelligent ore sorting machines will continue to expand their application scope in the market and become a key tool for mining modernization.

https://www.mdoresorting.com/ai-intelligent-mineral-ore-sorting-machine

https://www.mdoresorting.com/ai-intelligent-mineral-ore-sorting-machine

Hefei Mingde Optoelectronics Technology Co., Ltd. has been deeply engaged in the field of ore sorting for more than ten years. It is a high-tech enterprise specializing in the research and development, design, manufacturing, sales and service of intelligent sorting robots and mining equipment for mining. It is the first to introduce AI intelligent technology in the field of visible light sorting in China, and launched AI intelligent ore sorting machines with practical application value. It has made great progress in ore sorting, greatly expanded the types of ore sorting of traditional color sorters, and has better performance.Thousands of machines have been put into practical application in domestic mining companies in China.