Subscribe to our newsletter and always be the first to hear about what is happening.

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024Overview of photoelectric sorting technology

Photoelectric sorting technology is a technology that uses optical principles to automatically identify and classify materials. It detects the optical properties of materials, such as color, gloss, transparency, etc., through photoelectric sensors, and then determines whether it has the required characteristics through preset intelligent algorithms, and performs corresponding separation processing. This technology is widely used in industries such as mining, agriculture, food processing, and waste material recycling, especially in improving sorting efficiency and accuracy, reducing labor intensity, and reducing environmental pollution.

Working principle of photoelectric sorting technology

The working principle of photoelectric sorting technology involves several key components: light source system, sensor system, signal processing system, and execution system. First, the light source system provides light of different wavelengths to illuminate the material to be detected, so that the reflected light presents different colors. The sensor system, usually a linear array CCD sensor, captures these lights and converts them into electrical signals. The signal processing system processes these electrical signals, analyzes the characteristics of the materials through image processing algorithms, and classifies them according to preset standards. Finally, the execution system sorts the sorted materials, usually by high-speed airflow or robotic arms to exclude defective products and retain high-quality products.

Application of photoelectric sorting technology in mining

In the mining field, photoelectric sorting technology is mainly used for pre-sorting of ore to improve the overall grade of ore and reduce the cost of subsequent processing. For example, in the process of phosphate ore sorting, photoelectric sorting technology can effectively identify and remove low-grade ore and debris, thereby improving the efficiency of mineral processing and reducing energy consumption. In addition, this technology can also be used to process phosphate resources with fine particle size and complex embedded morphology, so that resources that were originally difficult to develop and utilize economically and efficiently can be fully utilized.

Advantages and challenges of photoelectric sorting technology

The advantages of photoelectric sorting technology lie in its high precision, high efficiency and environmental protection characteristics. It can complete the sorting of a large number of materials in a short time without adding chemical reagents, reducing pollution to the environment. However, the technology also faces some challenges, such as adapting to the sorting needs of more types and complex ore structures, improving the stability and anti-interference ability of the system, and reducing costs.

Future development of photoelectric sorting technology

With the continuous advancement of technology, photoelectric sorting technology is expected to further improve recognition accuracy and stability in the future, expand the scope of application, and play a greater role in mining and other fields. For example, by combining technologies such as artificial intelligence and big data analysis, the photoelectric sorting system will become more intelligent and automated, and can better adapt to different working environments and sorting requirements.

Application of MINGDE Optoelectronic Sorting Technology

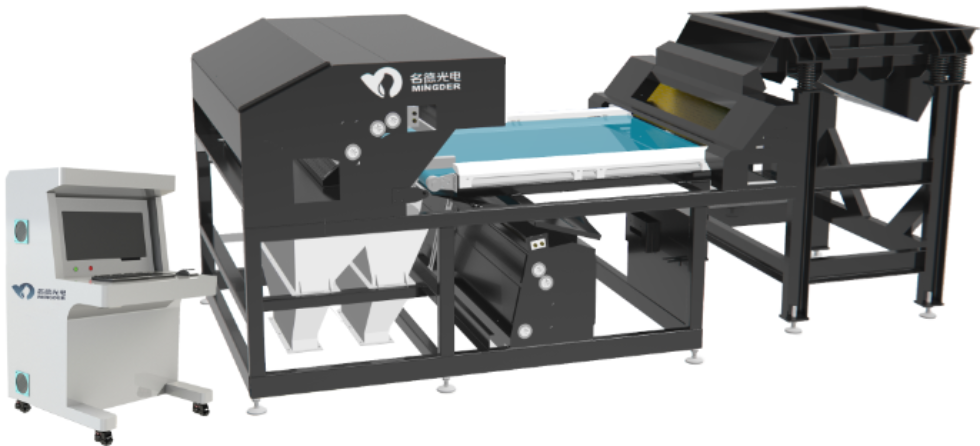

Hefei MINGDE Optoelectronic Technology Co., Ltd., as a leading enterprise in the field of mining sorting in China, has taken the lead in introducing artificial intelligence, big data sorting and other technologies in the field of ore photoelectric sorting, expanding the variety of ore sorting by photoelectric sorting machines, and making the sorting effect more accurate. The heavy-duty machine developed by the company can sort ores with larger particle sizes, which brings about greater output and meets the requirements of mining companies for large-scale ore sorting.

Since its establishment in 2014, the company has been working hard in the field of ore sorting for ten years. The staff visited various mining areas in China on the spot, fully communicated with various mining companies, and deeply understood the various requirements of the mines for sorting equipment. The overall structure of the MINGDE sorting machine adopts a split structure to avoid the influence of feeding vibration on the main part of the machine sorting, ensuring the accuracy of sorting; using a conveyor belt instead of a chute reduces the trouble of frequent replacement of wearing parts of the chute machine. The whole machine is coated with an anti-corrosion coating, which improves the adaptability of the machine to the harsh working environment of high dust, high pollution and high corrosion in the mining industry.

MINGDE Optoelectronic Technology Co., Ltd. has always believed that integrity makes MINGDE a success and MINGDE creates the best corporate mission. We are willing to work together with friends from all walks of life to achieve the long-term development of mining intelligence and automation.