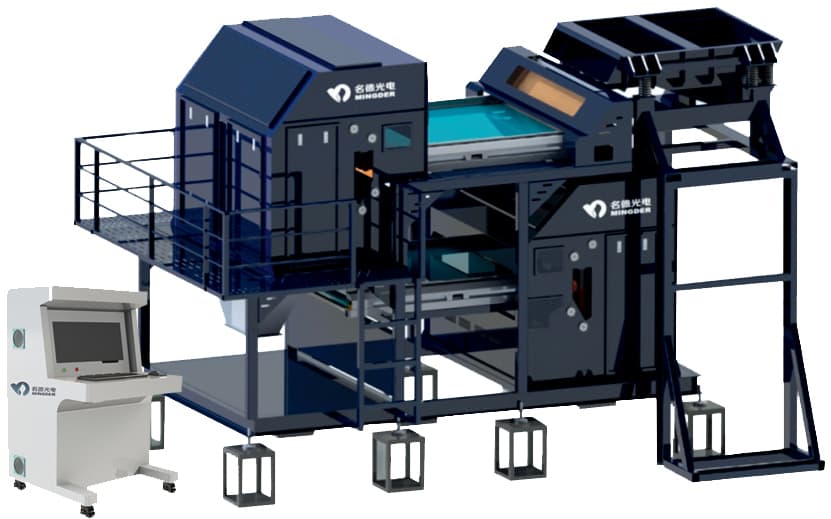

AI Photoelectric Sorting Technology can be compound one -step sorting .It will improve the ore grade and reduce the prduction cost.

Mingde Optoelectronics Artificial Intelligence Sorting equipment take the lead in introducing artificial intelligence methods such as deep convolutional neural networks(CNN) in the field of visible light photoelectic sorting to analyze and process material images,and through CNN partial connection,weight sharing,multiple convolution kernels and other methods,during the training process, the multi-dimensional features of materials are automatically extracted to establish a database,whose sorting effect is far better than traditional photoelectric methods.

Packing :

AI mineral sorting machineBrand :

MingderMOQ :

1Origin :

ChinaColor :

customizedHefei Mingde Optoelectronic Technology Co., Ltd. is a domestic high-tech enterprise.Specializing in R&D,production and sales of industrial and mining intelligent ores sorting machine,which located in a national science and education city-Hefei,owning a production and research base covered an area of 40 acres, with 20,000 square meters of standard workshop and scientific research center.

Technical Advantages:

1.Introduced artificial intelligence methods CNN in the field of visible light photoelectric sorting to analyze and process material images.

2.Al photoelectric sorting technology can automatically extract the multi-dimensional characteristics of materials, like texture, shape, color, quality, Luster, etc., which greatly improves the sorting effect, expands the sorting scene and material types, to meets the market diversification and personalized sorting requirements, and solves the problem of limited color sorting materials in the current color sorter market.

3.Photoelectric sorting requires high real-time performance, while CNN operation is relatively slow. In this regard, we adopt the model compression technology to accelerate CNN operation speed and greatly improve the recognition efficiency.

4.In view of the situation that many mineral materials cannot obtain massive data, our company adopts transfer learning technology and industrial image sample enhancement technology to ensure the recognition accuracy of non-massive data training.

5.The Al sorting machine uses a gigabit camera to transmit image data to a multi- GPU computing platform, which adopts CNN to analyze material types and accurately identify material surface features and texture structures.

Working Principle:

Al ore separation principle of the separator is artificial intelligence using high accuracy intelligent camera for ore, gangue pictures respectively, distinguish between the two surface color, texture, the inherent characteristics of difference, industrial intelligent computer constantly learning and memory, mineral processing, such as computers, the system will automatically by the complex algorithm of discrimination ore, gangue, issuing commands using the aerodynamic force for precise separation in a timely manner.

Our Advantage :

1.It's the machine with multi-function,strong adaptability,and the maximum e-

xtent to shorten the sorting process, reduce user equipment investment, and imp-

rove sorting efficiency.

2.It can improve the sorting effect through learning.

3.High intelligence, remote debugging, smart monitoring, remote service and

software upgrade.

Product feature of AI sorting machine

1,it’s the first to introduce artificial intelligence means of neural network in the field of sorting,which solves the problem that color sorting machine can only separate according to simple criteria.

2, The sorting mode is established according to users’ sorting requirements to meet users’ diversified and personalized sorting requirements.

3,We own the self-developed software system and closed machine structure, the main internal components are all imported,which can adapt to the harsh environment requirements like high dust,high pollution, and high corrosion in the industry and mining area.It has a wider application range and longer life.

4,Flexible track-type material conveying system,with samll drop,large output,and suitable for the sorting of more materials.

5,The vibrating feeding part and the main part of the equipment adopt a split structure to avoid the impact of vibration generated during the feeding process on the host and make the equipment operation more stable.

6, the sorting effect can be continuously improved by learning mode, and the deep learning mode can be developed.

7,High intelligence,remote debugging,smart monitoring,remote service and software upgrading.

Sortable ores

Applicable sorting ore materials

Talc, wollastonite ,calcite, quartzite

Fluorite, Potassium feldspar, Magnesite, Lithium pyroxene

Phosphate ore, Gold ore, High crystal silicon, oxide copper ore

Barite, bauxite ,lead-zinc ore and fluorite, barite lead-zinc ore

Not limited to the above ores, eye visible distinctions are applicable to AI sorting machines!

Tags :