Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

Potassium feldspar is a common feldspar mineral with the chemical formula NaAlSi3O8, belonging to the category of sodium aluminum silicate. It usually appears as glassy crystals and can be colorless, white, yellow, red or black. Potassium feldspar is most common in pegmatites and felsic igneous rocks such as granite, and is also found in low-grade metamorphic rocks and some sedimentary rocks.

The hardness of potassium feldspar is about 6-6.5, the density is between 2.61-2.64 g/cm³, and the melting point is about 1100℃. Its theoretical chemical composition is Na2O: 11.8%, Al2O3: 19.4%, SiO2: 68.8%, but this theoretical value is difficult to achieve in nature.

The classification of potassium feldspar usually based on its chemical composition and crystal structure. According to the chemical composition, potassium feldspar can be divided into different subspecies, such as albite, oligoclase and bytownite. According to the crystal structure, it can be divided into monoclinic system and triclinic system. These classifications are instructive for understanding the physical and chemical properties of potassium feldspar and its application in industry.

Potassium feldspar plays an important role in the ceramic industry. It can be used as a flux, a ceramic body ingredient and a glaze. Before firing, potassium feldspar can reduce the drying shrinkage and deformation of the body, improve the drying performance and shorten the drying time. During firing, it can be used as a flux to reduce the firing temperature and improve the light transmittance of the body.

potassium feldspar is also one of the important raw materials in the glass industry. It can increase the alumina content in the glass mixture, reduce the melting temperature, and adjust the viscosity and chemical composition of the glass.

In addition, potassium feldspar is also used in the chemical industry, abrasives and tools, welding rods and other industries. For example, it can be used as a raw material for enamel, the main raw material for refractory materials, and as a filler in detergents, toothpaste, cosmetics and other industries.

The purity of potassium feldspar directly affects its application effect in industrial production. For example, in the ceramic industry, high-purity potassium feldspar can significantly reduce the firing temperature and improve the quality and performance of the product. Therefore, accurately judging the purity of potassium feldspar is of great significance to ensure product quality and production efficiency.

The determination of potassium feldspar purity usually involves the following aspects:

Chemical composition analysis: Through chemical analysis methods such as ICP, XRF, AAS, etc., the main components of potassium feldspar, such as SiO2, Al2O3, Fe2O3, TiO2, K2O and Na2O, can be accurately determined. The content of these components directly reflects the purity of potassium feldspar.

Physical property test: Including tests of physical properties such as hardness, density, melting point, etc., these properties can also indirectly reflect the purity of potassium feldspar.

Mineral composition analysis: Through methods such as X-ray diffraction (XRD), the mineral type and content of potassium feldspar can be determined, which is also a method to judge purity.

The main method of impurity separation

Flotation method: By adding different flotation agents, the surface properties of potassium feldspar and other impurity minerals are changed, thereby achieving separation.

Magnetic separation: Separate iron-containing impurities from potassium feldspar by using magnetic differences.

Chemical impurity removal technology: Dissolve and remove impurities in the ore by acid washing and other methods.

High-temperature chlorination method: Use high temperature and chlorine to separate impurity iron from potassium feldspar.

Microbial method: Use microbial metabolites to react with iron impurities, and then use other methods to remove impurities.

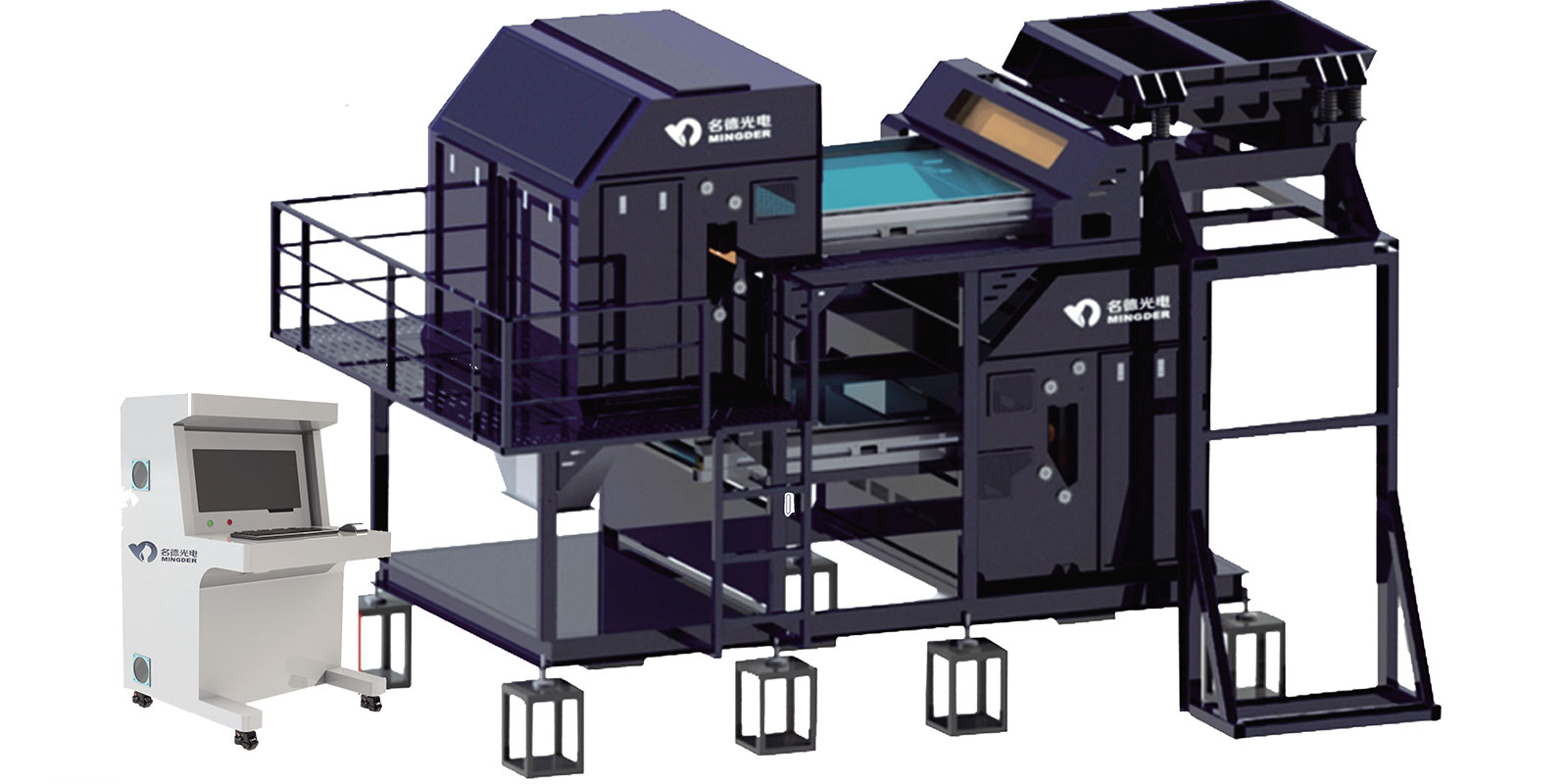

Photoelectric sorting: This is an emerging ore sorting technology that combines photoelectric detection and artificial intelligence algorithms to achieve intelligent ore sorting by identifying multi-dimensional features such as spectral characteristics, texture, and color of the ore. This technology has significant advantages in improving ore sorting efficiency, reducing costs, protecting the environment, and promoting resource recovery.

https://www.mdoresorting.com/wet-intelligent-minerals-separator-ore-sorting-machine-leading-manufacturer-of-china

High efficiency: Photoelectric sorting technology can quickly remove a large amount of useless gangue, reduce the pressure of subsequent mineral processing links, and improve sorting efficiency.

Low cost: Compared with traditional physical mineral processing and chemical mineral processing, the cost of photoelectric mineral processing is lower, and the cost of mineral processing per ton is about $0.15.

Environmental protection: Photoelectric mineral processing technology has zero pollution to the environment and is a greener mineral processing method.

Technological progress: With the development of computer technology and artificial intelligence technology, the intelligence level of photoelectric mineral processing equipment has been continuously improved.

Strong adaptability: By introducing cutting-edge technologies such as artificial intelligence and big data analysis, the intelligence level and adaptability of the photoelectric sorting system have been greatly improved.

High safety: Photoelectric mineral processing equipment does not need to add any chemical agents during operation, avoiding the safety risks that may be caused by chemical agents.

Technological innovation: China is in a leading position in the research and development of core components in the intelligent photoelectric mineral processing equipment manufacturing industry.

Resource recovery: Photoelectric sorting technology has significant advantages in processing low-grade ore resources, and can fully recycle and utilize ore resources that were originally difficult to develop and utilize economically and efficiently.

System stability: Photoelectric sorting technology is still in the development stage, but through continuous technological innovation and optimization, the stability and anti-interference ability of the system are constantly improving.

Cost-effectiveness: The research and development and application of photoelectric mineral processing technology always focus on cost control and cost-effectiveness.

Application and Advantages of MINGDE AI Sorter in Non-metallic Ores

Jun 03, 2024

Application and Advantages of MINGDE AI Sorter in Non-metallic Ores

Jun 03, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

Photoelectric Separation: Helping to Enrich the Grade of Gold Mines

Jul 27, 2024

Photoelectric Separation: Helping to Enrich the Grade of Gold Mines

Jul 27, 2024