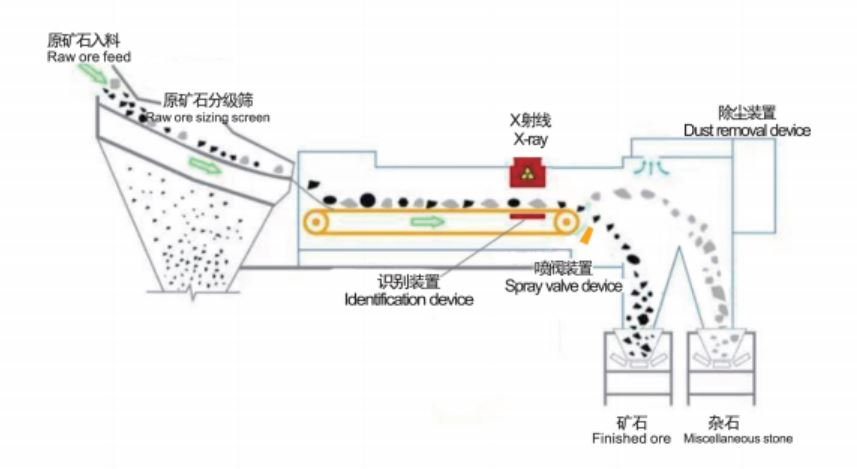

The X-ray intelligent mineral sorting machine uses X-ray rays to scan the selected ore to obtain the atomic number data of the minerals contained in the ore. The data is processed by means such as convolutional neural network, and the recognition model is established to identify Ore and miscellaneous stones, and then drive the actuator to carry out ore sorting.In addition,the visible light or infrared camera can be added for composite identification to further improve the sorting accuracy according to the different characteristics of the ore.

Working principle

Raw ores go into the feed funnel and screen fine particles through vibrating screen. Then the left ores go to the belt. When the ores are under the X-ray, X-rat will penetrate them and form an image according to different density. According the image, control system will give an order to open the electromagnetic valve to blow the miscellaneous stone.

The X-ray intelligence sorting separator can process ore particle size range from 10mm to 300mm, taking the mineral density 1.4g/cm3 as a example, the processing capacity of a single device can reach up to 380t/hour

Technical advantage

1. The high-precision and dual-energy acquisition we developed independently can not only identify minerals with large density and high content, but also identify minerals with small density and low content, which is suitable for many minerals separation.

2. X-ray intelligence sorting separator adopts deep learning and other AI methods to establish a unique mathematical model for each mining to ensure the accuracy of the recognition and the efficiency of sorting separation.

Application

Application

1. X-ray colour sorting separator can sort coal and gangue. The gangue discharge rate is more than 96%, and the carry-over rate is 1-3%; low unit energy consumption, the average power consumption is less than 1kwh/h.

2. Metal ores and non-coal mines can be sorted by X-ray colour sorting separator, such as lead and zinc, copper, nickel, manganese, fluorite, brucite, phosphate rock, solid waste, smelting waste,etc.

3. The X-ray intelligence sorting separator can control scrap rate accurately.

Experiment Data:

Mingde X-ray intelligence color sorter doing 5 groups of selection experiments.

| sample number | category | Zn (%) | Sn(%) | Pb(%) | scrap rate (%) |

| 1 | concentrate | 2.11 | 0.54 | 0.12 | 36.73 |

| tailing | 0.21 | 0.013 | 0.016 | ||

| 2 | concentrate | 2.74 | 1.04 | 0.25 | 41.38 |

| tailing | 0.18 | 0.022 | 0.017 | ||

| 3 | concentrate | 6.21 | 0.76 | 0.17 | 47.33 |

| tailing | 0.21 | 0.015 | 0.019 | ||

| 4 | concentrate | 3.29 | 1.04 | 0.21 | 56.30 |

| tailing | 0.15 | 0.0066 | 0.018 |

Tags :